Continuous casting device capable of achieving continuous feeding and production of high-purity single crystal copper rods

A continuous casting and single crystal technology, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of increased production costs, unqualified single crystal copper grains, waste, etc., to reduce production costs, The method is reasonable and feasible, and the effect of reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

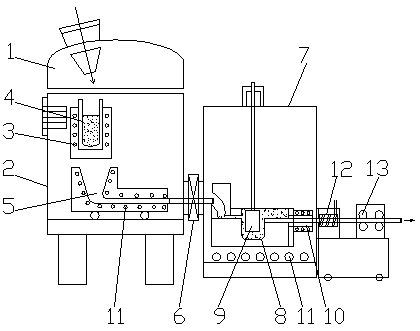

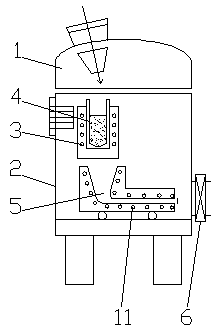

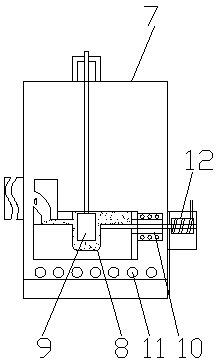

[0022] A continuous casting device for producing high-purity single crystal copper rods by continuous feeding, comprising a vacuum furnace cover 1, a vacuum melting furnace 2, a melting crucible 4, a vacuum gate valve 6, a heat preservation continuous casting pot 7, a continuous casting crucible 8, and a crystallizer 10. Cooling water jacket 12 and traction winding mechanism 13. The vacuum melting furnace 2 communicates with the inlet end of the heat preservation continuous casting pot 7 through the vacuum flapper valve 6, and the outlet end of the heat preservation continuous casting pot 7 is connected with the cooling water through a seal. The sleeve 12 is connected with the traction and winding mechanism 13; after the raw copper plate is melted in the melting crucible 4, the protective gas is introduced, the vacuum fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com