Integrated water tank and pipeline-type water dispenser provided with integrated water tank

An integrated, water dispenser technology, applied in the field of water dispensers, can solve the problem of water being difficult to be used efficiently, and achieve the effect of stable liquid level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

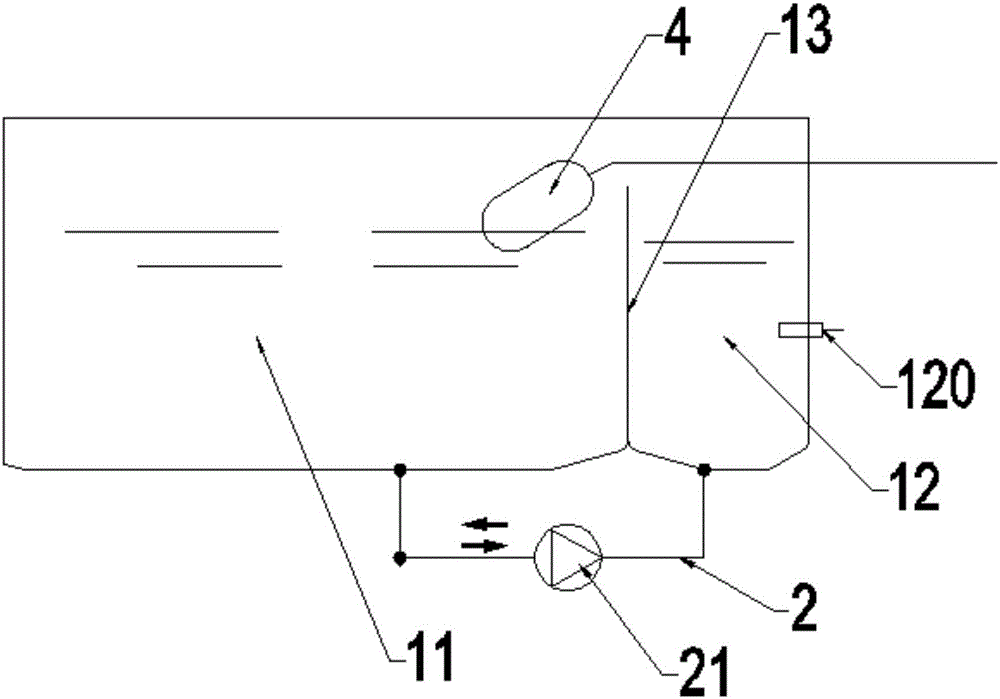

[0024] The integrated water tank includes a water tank body, which is provided with a first partition 13 that separates the water tank body into a raw water tank 11 and a balance water tank 12 . The height of the first dividing plate 13 is less than the height of the water tank body, and the volume of the balance water tank 12 is less than the volume of the original water tank 11. A return pipe 2 is provided between them, and a water pump 21 is provided on the return pipe 2; a water inlet, a water outlet and a water level switch 120 for detecting the water level in the balance water tank 12 are provided on the balance water tank 12. The raw water tank 11 is provided with a float switch 4 for controlling water intake at the water inlet.

[0025] In this embodiment, through the integrated design of the balance water tank 12 and the original water tank 11, the volume of the whole machine can be effectively reduced, and the cost can be reduced. At the same time, the original water...

Embodiment 2

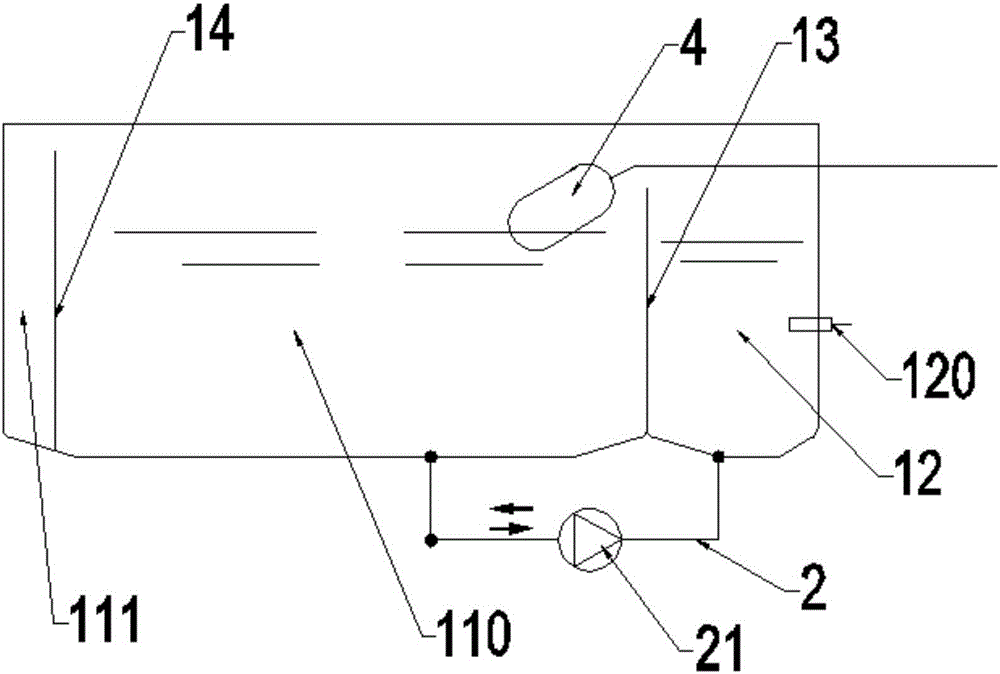

[0028] Same as embodiment 1, the difference is that a second partition 14 is arranged in the water tank body, the second partition 14 is located in the raw water tank 11 and separates the raw water tank 11 into a water storage chamber 110 and an exhaust chamber 111, the exhaust chamber 111 is provided with an air inlet and an exhaust port, so the water tank body is divided into three parts: the exhaust chamber 111, the water storage chamber 110 and the balance water tank 12 by the first partition 13 and the second partition 14, and the volume of the balance water tank 12 It is one-third of the volume of the water storage chamber 110 . By setting the exhaust chamber 111 in the water tank, when the water tank is connected to the heating body 5, the steam is partially liquefied through the exhaust chamber 111 and becomes a gas-liquid mixture and then discharged through the exhaust port. The exhaust chamber 111 is also integrated in the water tank. On the water tank body, the stru...

Embodiment 3

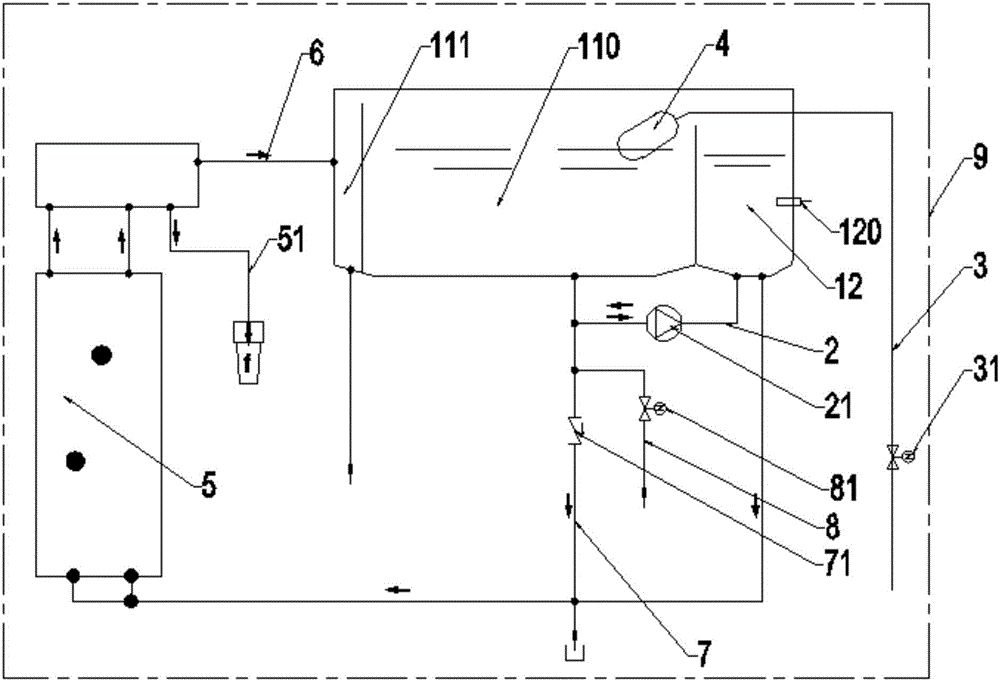

[0030] The pipeline water dispenser includes the integrated water tank in embodiment 1 or 2. The water inlet of the balance water tank 12 is connected with a water inlet pipe 3, and the water inlet pipe 3 is provided with a water inlet solenoid valve 31.

[0031] Also includes heating body 5, heating body 5 is connected with the water outlet of balance water tank 12, is provided with hot water outlet on heating body 5, and hot water outlet place is provided with hot water outlet pipe 51; The distance from the bottom is greater than the distance from the top of the first partition 13 to the bottom of the balance water tank 12 .

[0032] The water flow first enters the balance water tank 12 through the water inlet. Because the volume of the balance water tank 12 is smaller than the original water tank 11, the balance water tank 12 is easily filled with water, so that the water level switch 120 in the balance water tank 12 is closed. When the machine heats hot water, the user Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com