Method modifying horizontal flow sedimentation tank into sedimentation floatation tank and modified sedimentation floatation tank

A technology of advection sedimentation tank and sedimentation air flotation, which is applied in the direction of separation method, flocculation/sedimentation water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problem of short shutdown time of water treatment system, system demolition and reconstruction, filter Problems such as filter material caking and clogging can be achieved to improve the treatment effect and operation stability, solve production problems, and stabilize the liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

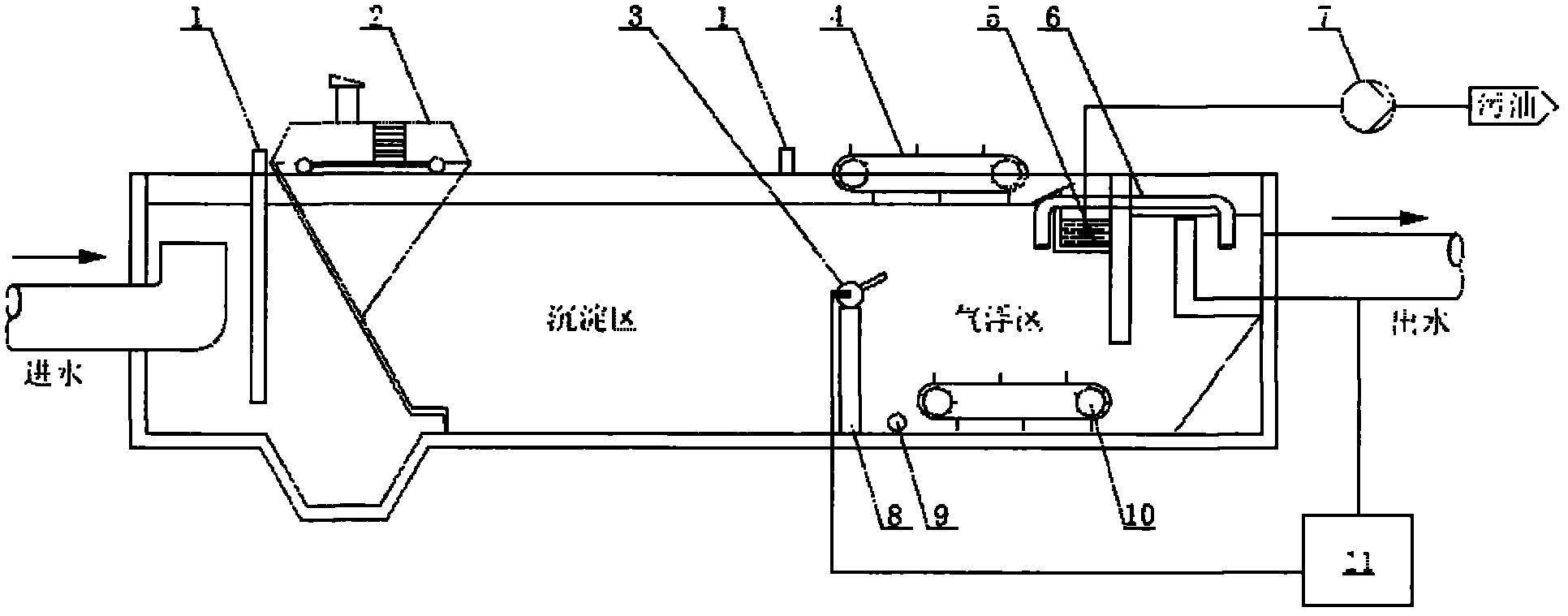

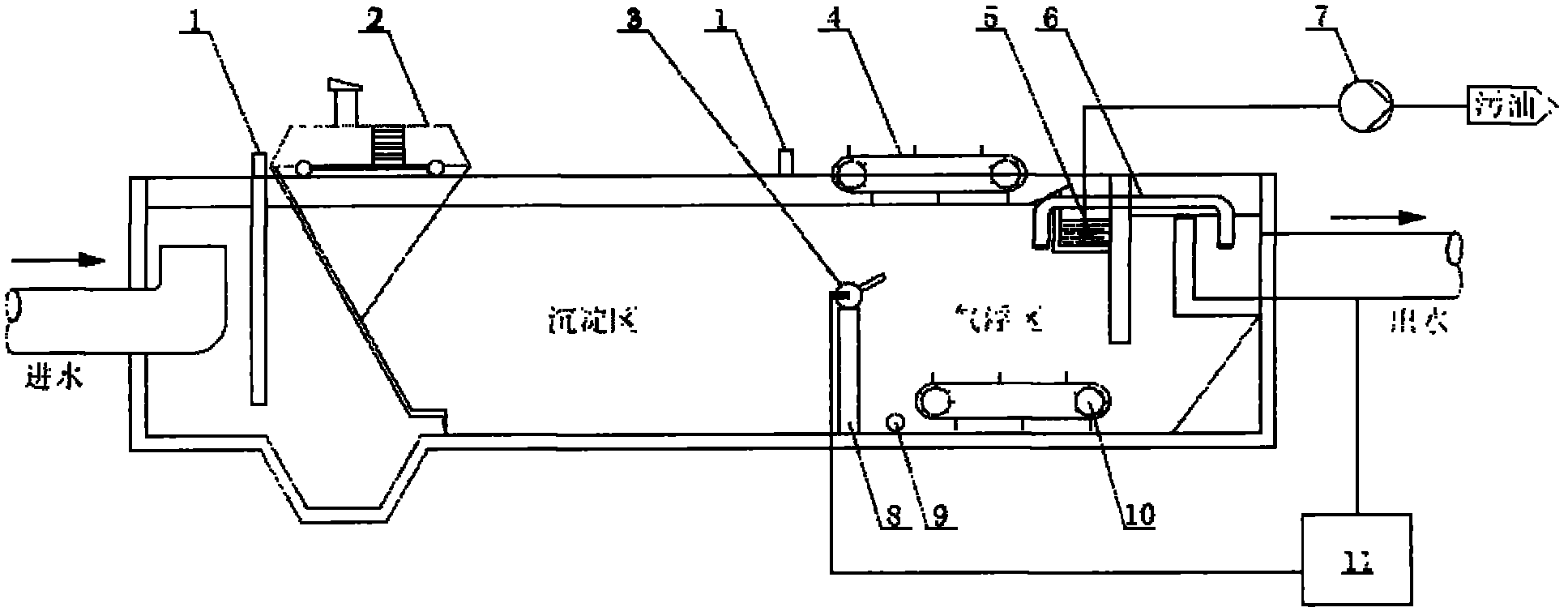

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, the present invention retains the overall structure and sludge discharge equipment and facilities of the original advection sedimentation tank. There is a water outlet, the specific transformation process is as follows: so the various processes can be in no order.

[0026] (1) Use the partition device 8 to divide the advection sedimentation tank into relatively independent sedimentation areas and air flotation areas along the direction of water flow. The specific position of the separation device 8 in the original advection sedimentation tank is located at one-half to three-thirds of the water flow direction of the advection sedimentation tank. In two places, the bottom of the separation device 8 is directly installed on the bottom of the advection sedimentation tank, and the top is 1 to 1.5 meters away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com