Continuous casting method and device for aluminum alloy compounded ingot

A technology of composite ingot and aluminum alloy, which is applied in the field of aluminum alloy casting to achieve the effects of improving the yield, easy realization and control, and no pores, looseness and impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

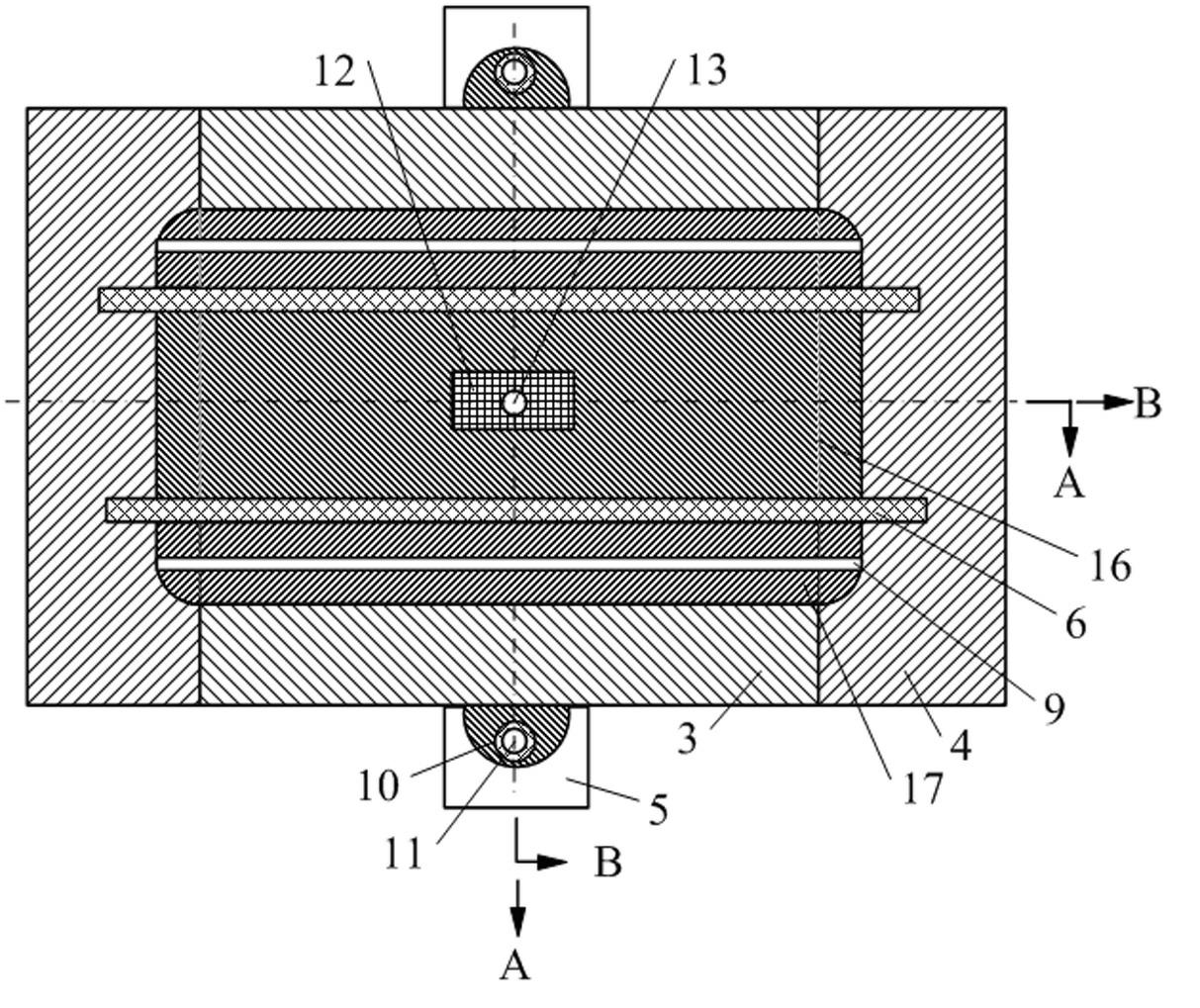

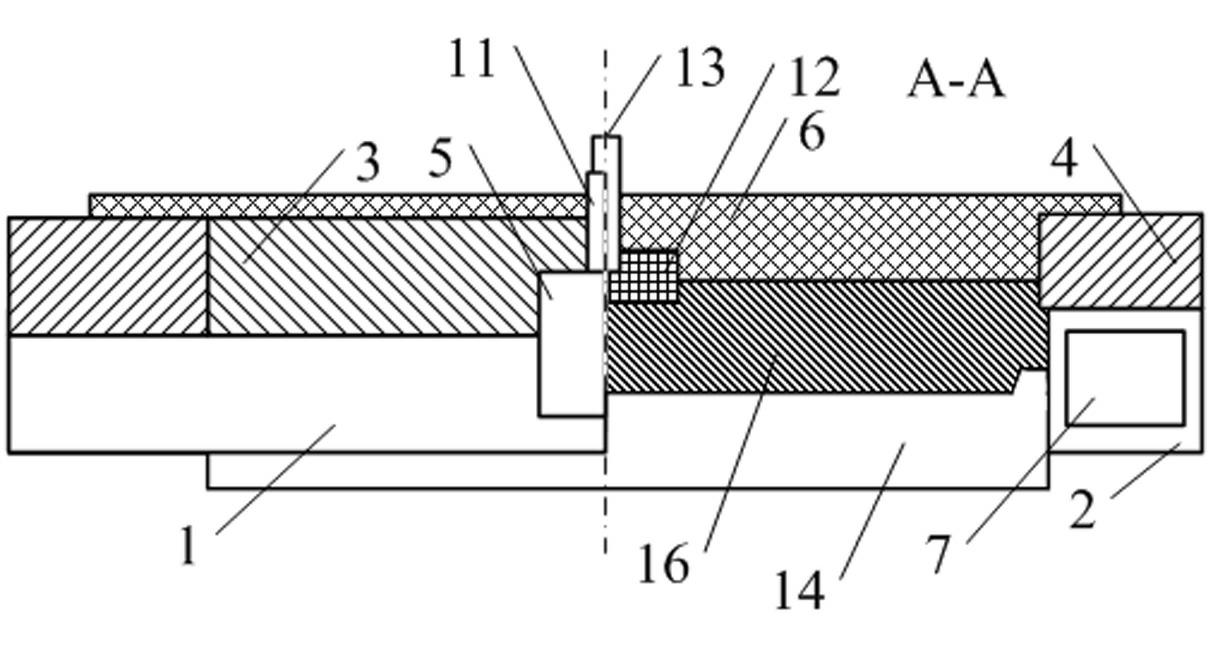

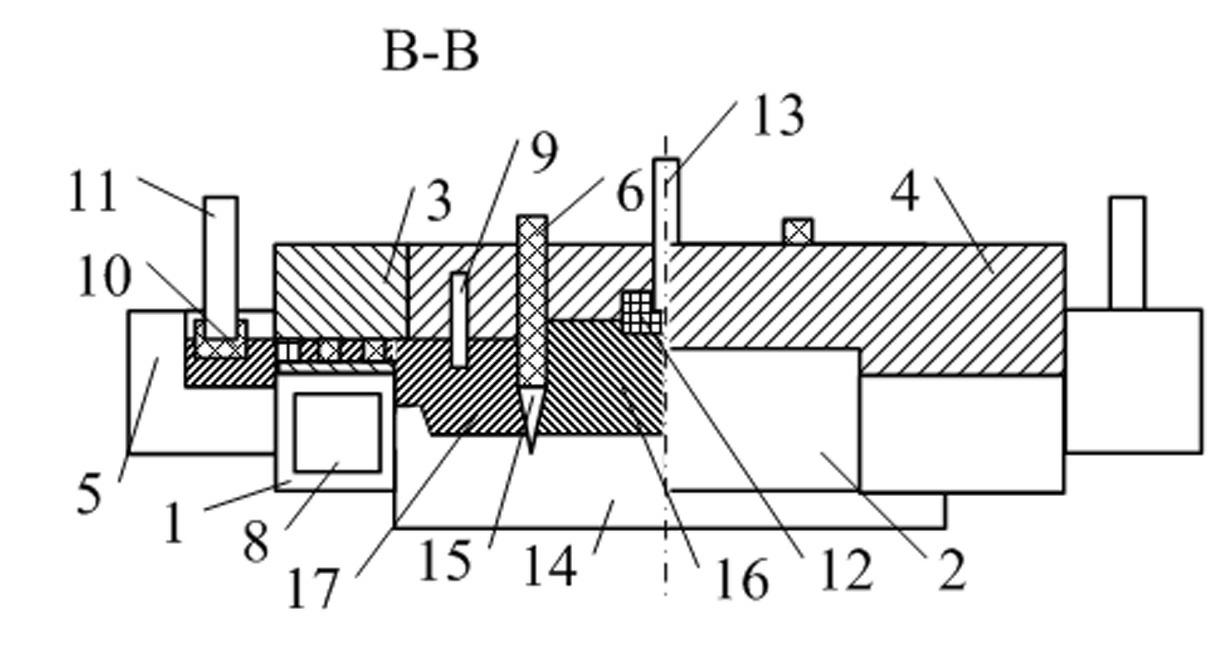

[0057] The continuous casting device structure of aluminum alloy composite ingot is as follows: figure 1 As shown, the A-A section structure is as follows figure 2 As shown, the cross-sectional structure of B-B plane is as follows image 3 As shown, it includes split crystallizer, alloy liquid distributor 3, hot top plate 4 and dummy ingot 14;

[0058] Split crystallizer structure such as Figure 4 with Figure 5 As shown, it is composed of two large surface water tanks 1 and two side water tanks 2;

[0059] In the continuous casting device for aluminum alloy composite ingots, an alloy liquid distributor 3 is connected above each large surface water tank 1, a hot top plate 4 is connected above each side water tank 2, and dummy ingots 14 are located at the bottom of the split crystallizer, each The lower surface of the hot top plate 4 is connected to a side water tank 2 and two large surface water tanks 1 at the same time; the two ends of each alloy liquid distributor 3 ar...

Embodiment 2

[0083] The structure of the continuous casting device for aluminum alloy composite ingot is the same as that in Example 1, the differences are: (1) the top of the large surface water tank is higher than the top of the side water tank, and the height difference between the two is 30 mm; (2) the material of the hot top plate is Calcium silicate board, the height is 180mm, and the height of the alloy liquid distributor is 150mm; (3) The bottom of the front plate of the cooling plate is 20mm lower than the upper edge of the large water tank; the heat insulation layer of the front plate is located in the melt chamber of the surface material of the cooling plate One side; (4) The inner wall of the split crystallizer is made of copper; (5) One end of the alloy liquid distributor extends to the inside of the split crystallizer, and the distance between the extended end and the inner wall of the split crystallizer is 5mm; one end of the hot top plate Extend to the inside of the split cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com