Recovery and treatment technology of dirty oil produced in sewage setting tank in produced liquid treatment

A treatment process and sewage recovery technology, applied in the direction of electric/magnetic dehydration/demulsification, chemical dehydration/demulsification, etc., can solve the problems that affect the normal production and operation of the crude oil dehydration system, and the electric field of the electric dehydrator collapses, etc., to achieve Simple implementation, convenient operation, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

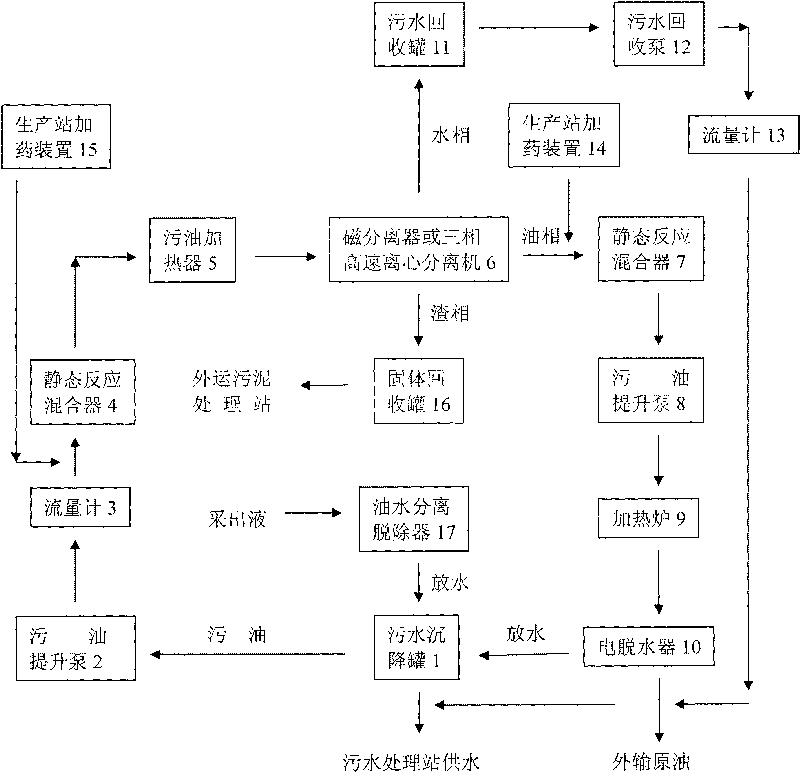

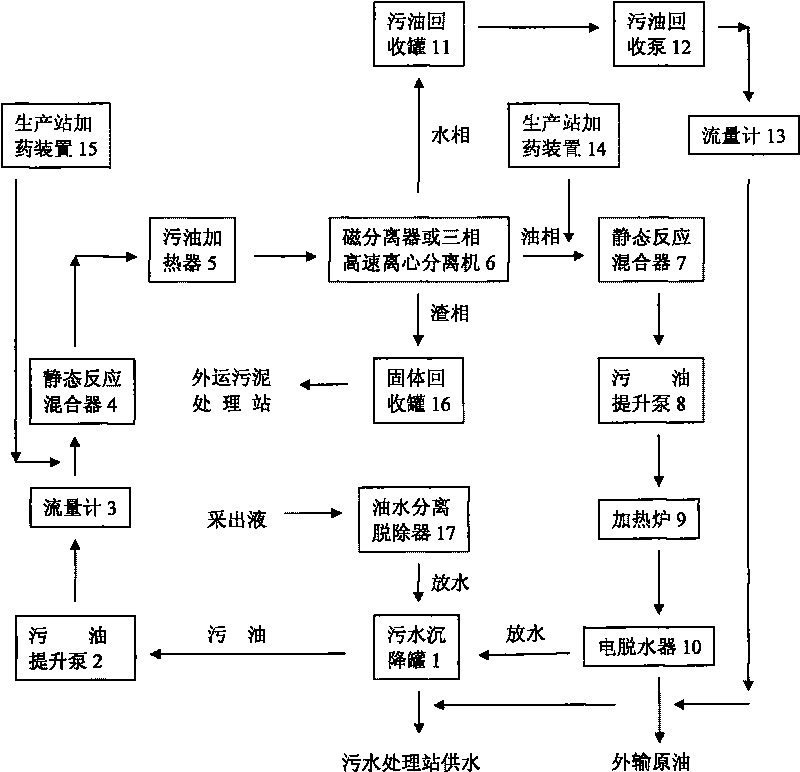

[0011] combine figure 1 Shown, the waste oil recovery treatment process step of the present invention is as follows:

[0012] The production fluid produced by the oil well is treated by the oil-water separator 17 of the oilfield joint station, and the separated sewage after treatment enters the sewage settling tank 1, and the sewage oil produced in the sewage settling tank 1 is lifted by the sewage oil lifting pump 2 through The flow meter 3 enters the static reaction mixer 4, and at the same time, one or two of the dirty oil demulsifiers SO1001, SO1002 or SO1003 are added using the dosing device 15 in the production station, and the dosing amount is usually 30-50 mg / L, alternately add more than two kinds of dirty oil demulsifiers that can destroy ferrous sulfide particles to form a rigid interfacial film on the oil-water interface; after adding the demulsifier, the dirty oil is mixed in the static reaction mixer 4 and then enters the dirty oil heater 5 , heated up to 40-50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com