Lifting type rail insulation operation platform

An operating platform and lifting technology, which is applied in the direction of hoisting devices, overhead lines/cable equipment, etc., can solve problems such as the inability to adjust the working height up and down, achieve the effect of ensuring uninterrupted power supply, ensuring safe and normal power supply, and solving practical problems in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

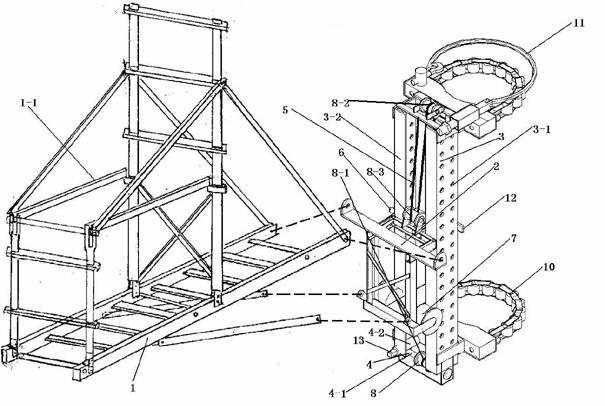

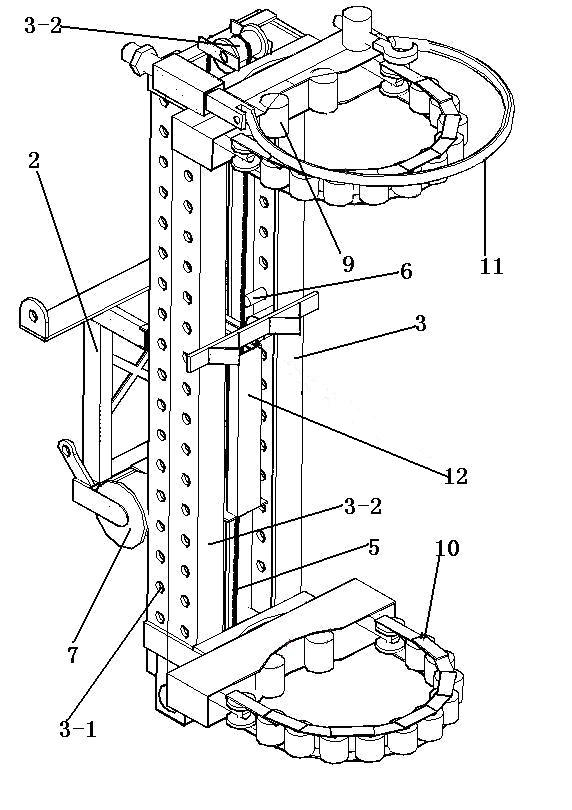

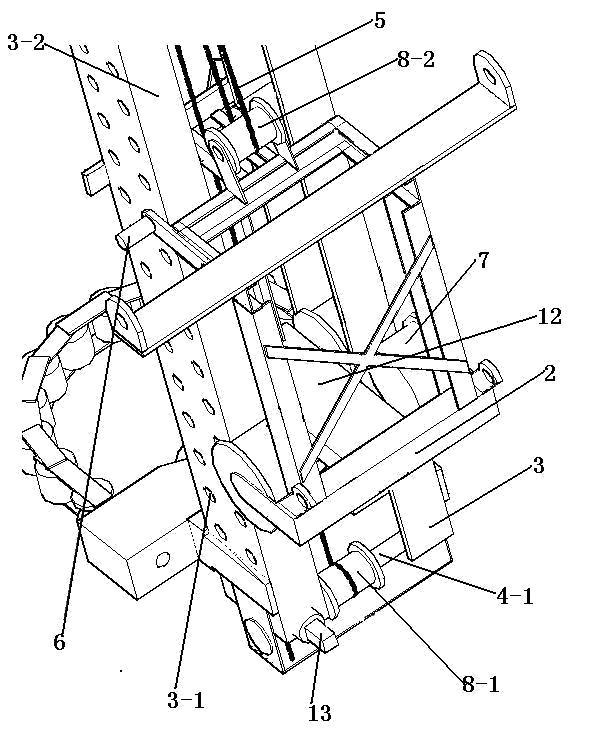

[0022] Such as figure 1 As shown, the present invention provides a lifting type fence insulation operation platform, the platform includes a moving device and an insulating platform body 1 provided with a fence 1-1; the moving device includes an up and down lifting device, a left and right moving device and an insulating platform support 2; The up and down lifting device includes a guide rail 3, a worm gear device 4, a pulley block, a lifting rope 5 and a lifting limiter 6; see figure 2 and image 3 , the front of the guide rail 3 faces the insulation platform body 1, and the back faces the pole column, and two columns of through holes 3-1 arranged at equal distances are correspondingly provided on the other two sides; the worm gear device 4 is arranged at the bottom end of the guide rail 3, the The worm wheel 4-2 is also provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com