Method for reducing SO3 concentration in diluted phosphoric acid

A technology of dilute phosphoric acid and phosphoric acid, applied in the field of dilute phosphoric acid, can solve problems such as influence, and achieve the effect of reducing the cost of the concentration process and saving the cost of the extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

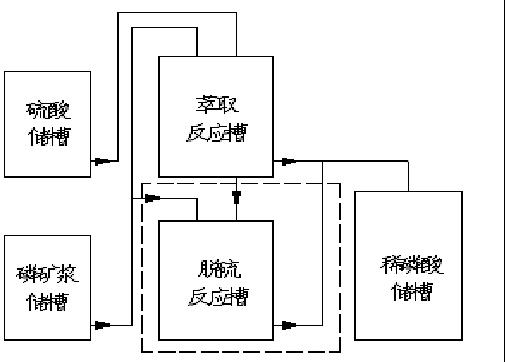

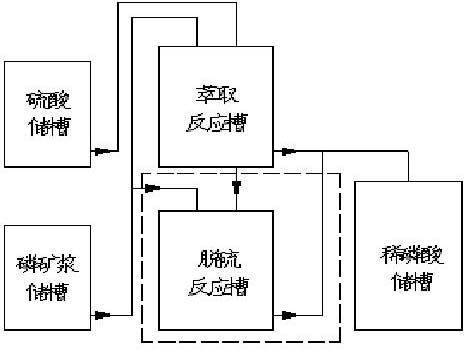

[0020] Guizhou Kailin (Group) Co., Ltd. has an annual output of 700kt of extracted phosphoric acid100%P 2 o 5 , as attached figure 1 , add a desulfurization tank between the phosphoric acid extraction tank and the dilute phosphoric acid storage tank, with a volume of 460m 3 , with 9 stirring paddles, double-layer paddles, rotating speed 69r / min, motor power 45kW.

[0021] Pass the filtered dilute phosphoric acid through the acid outlet pipe by 100m 3 / h is stably added to the desulfurization tank, and the ore pulp is also pumped into the desulfurization tank; before feeding, the filtered dilute phosphoric acid and the ore pulp are analyzed, and the dilute phosphoric acid SO 3 The concentration is 3.3%, the specific gravity is 1.31, the acid temperature is 60°C, the CaO content of the slurry is 46.12%, and the specific gravity is 1.85. According to the calculation formula, the addition amount of ore pulp is 3.55m 3 / h, that is, the acid ore ratio of the production process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com