Water and fertilizer integrated fertilizer special for winter wheat and application method for water and fertilizer integrated fertilizer

An application method and a special fertilizer technology, applied in the direction of fertilization methods, botanical equipment and methods, applications, etc., can solve the problems of inapplicable spring growth of wheat, unfavorable for saving water resources, spring drought in winter wheat production areas, etc., to improve the resistance Lodging ability, improvement of antioxidant enzyme activity, and the effect of uniform panicle layer in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

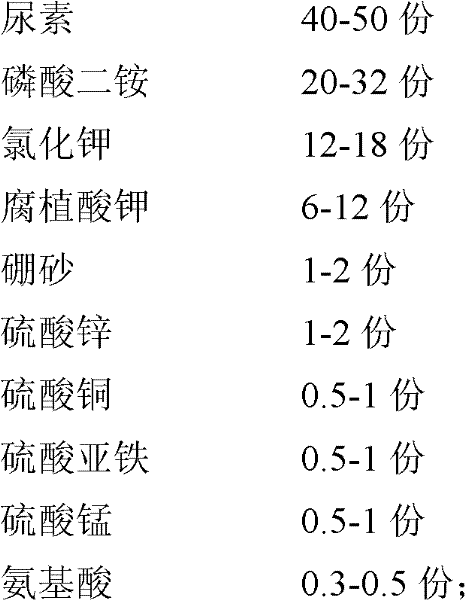

[0041] The invention discloses a special fertilizer A for the integration of water and fertilizer for winter wheat, which is mainly used for nutrient input for spray irrigation and fertilization of wheat from sowing to late jointing stage. Its proportioning raw material parts by weight are as follows:

[0042] 42 parts of urea, 28 parts of diammonium phosphate, 14 parts of potassium chloride, 10 parts of potassium humate, 1.5 parts of borax, 2 parts of zinc sulfate, 0.7 parts of copper sulfate, 0.8 parts of ferrous sulfate, 0.7 parts of manganese sulfate, 0.3 parts of amino acid .

[0043] The finished raw materials above are crushed, all passed through an 80-mesh sieve to form powdery solids, mixed evenly, and packed in bags to obtain the special fertilizer A for the integration of water and fertilizer for winter wheat. The special fertilizer for wheat is suitable for application in the form of spray fertigation after wheat sowing to jointing, and the application method is a...

Embodiment 2

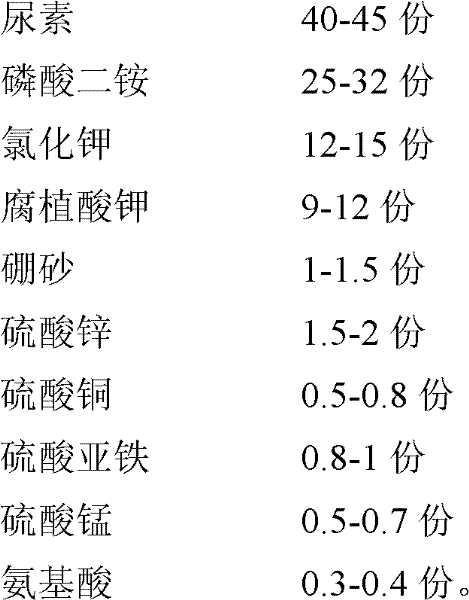

[0048] A special fertilizer B1 for the integration of water and fertilizer for winter wheat, which is mainly used for the nutrient input of spray irrigation and fertilization of wheat from the booting stage to the middle stage of grain filling. Its proportioning raw material parts by weight are as follows:

[0049] 49 parts of urea, 20 parts of diammonium phosphate, 17 parts of potassium chloride, 8 parts of potassium humate, 1.8 parts of borax, 1.2 parts of zinc sulfate, 0.9 parts of copper sulfate, 0.6 parts of ferrous sulfate, 1 part of manganese sulfate, 0.5 parts of amino acid .

[0050] The above-mentioned finished raw materials are crushed and passed through a 80-mesh sieve to form a powdery solid, which is weighed in parts by weight, mixed evenly, and packed in bags to obtain the special fertilizer B1 for the integration of water and fertilizer for winter wheat.

[0051] The special fertilizer for wheat is suitable for application in the form of spray fertilization fr...

Embodiment 3

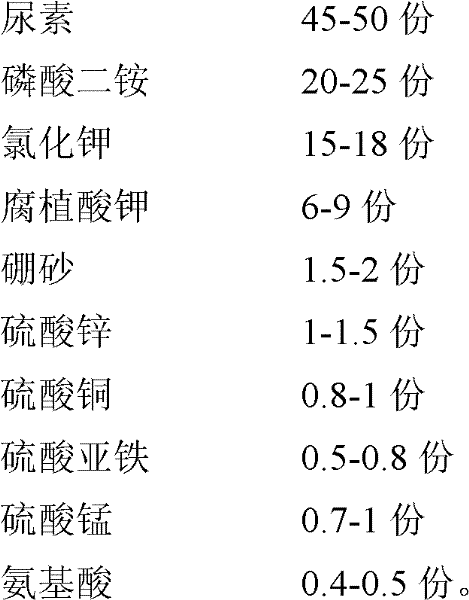

[0055] A special fertilizer B2 for the integration of water and fertilizer for winter wheat, its proportioning raw material weight parts are as follows:

[0056] 47 parts of urea, 22 parts of diammonium phosphate, 18 parts of potassium chloride, 7 parts of potassium humate, 2 parts of borax, 1.1 parts of zinc sulfate, 1 part of copper sulfate, 0.7 parts of ferrous sulfate, 0.8 parts of manganese sulfate, 0.4 parts of amino acid .

[0057] The above-mentioned finished raw materials are crushed and passed through an 80-mesh sieve to form a powdery solid, which is mixed evenly and packed in bags to obtain the special fertilizer B2 for the integration of water and fertilizer for wheat.

[0058] The special fertilizer for wheat is suitable for application in the form of spray fertilization from the late jointing stage to the mid-filling stage of wheat. The application method is as follows:

[0059] In the later stage of wheat jointing to the mid-stage of filling, apply 10-15kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com