Preparation method of hydroxy phosephorite hollow microball

A technology of hydroxyapatite and hollow microspheres, which is applied in the field of preparation of hydroxyapatite microspheres, can solve the problems of complex process, high crystallinity of microspheres, difficulty in wide-range adjustment, etc. The effect of large specific surface area and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

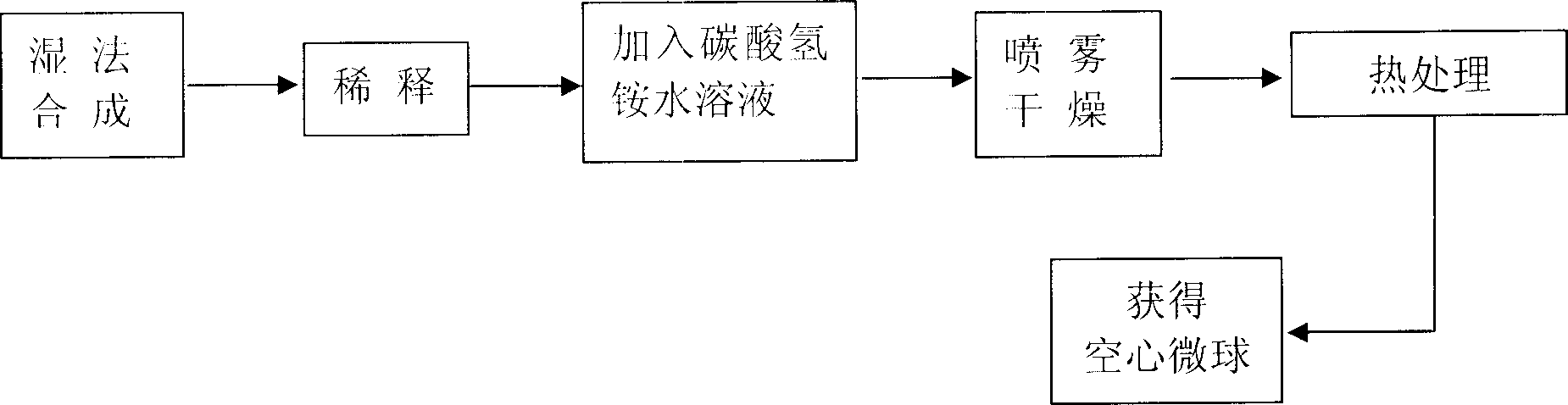

Method used

Image

Examples

Embodiment 1

[0033] (1) Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) as raw material, according to the ratio of calcium to phosphorus molar ratio of 1.67, the hydroxyapatite slurry is prepared by the chemical precipitation method in the wet method, wherein Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The ratio of the mass (g) to the volume (ml) of the final obtained slurry is: 2.98: 1: 17, and the specific chemical reaction formula is:

[0034]

[0035] (2) Dilute the hydroxyapatite slurry with distilled water at a ratio of 5:1 by volume ratio, and add ammonium bicarbonate at a concentration of 0.03 g / ml based on the volume of the diluted hydroxyapatite slurry , mix and stir evenly;

[0036] (3) Under the magnetic stirring speed of 400 rev / min, the above mixed solution is sprayed under the condition that the nozzle diameter is 1mm, the inlet air temperature is 180°C, the exhaust air temperature is 90°C, and the feeding a...

Embodiment 2

[0042] (1) Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) as raw material, according to the ratio of calcium to phosphorus molar ratio of 1.67, the hydroxyapatite slurry is prepared by the chemical precipitation method in the wet method, wherein Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The ratio of the mass (g) to the volume (ml) of the final obtained slurry is: 2.98: 1: 17, and the specific chemical reaction formula is:

[0043]

[0044] (2) Dilute the hydroxyapatite slurry with distilled water at a ratio of 5:1 by volume ratio, and add ammonium bicarbonate at a concentration of 0.01 g / ml based on the volume of the diluted hydroxyapatite slurry , mix and stir evenly;

[0045] (3) At a magnetic stirring speed of 350 rev / min, spray the above-mentioned mixed solution with a nozzle diameter of 1 mm, an inlet air temperature of 180°C, an exhaust air temperature of 90°C, and a feed rate of 20ml / min. dry;

[0...

Embodiment 3

[0049] (1) Calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 O) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) as raw material, according to the ratio of calcium to phosphorus molar ratio of 1.67, the hydroxyapatite slurry is prepared by the chemical precipitation method in the wet method, wherein Ca(NO 3 ) 2 4H 2 O and (NH 4 ) 2 HPO 4 The ratio of the mass (g) to the volume (ml) of the final obtained slurry is: 2.98: 1: 17, and the specific chemical reaction formula is:

[0050]

[0051] (2) Dilute the above-mentioned hydroxyapatite slurry with distilled water at a ratio of 5:1 by volume ratio, and add ammonium bicarbonate at a concentration of 0.05 g / ml based on the volume of the diluted hydroxyapatite slurry , mix and stir evenly;

[0052] (3) At a magnetic stirring speed of 500 rev / min, the above-mentioned mixed solution is sprayed with a nozzle diameter of 1mm, an inlet air temperature of 180°C, an exhaust air temperature of 90°C, and a feed rate of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com