Organic-inorganic compound fertilizer for grapes and method for preparing same

A technology of compound fertilizer and organic fertilizer, which is applied in the fields of organic-inorganic compound fertilizers for grapes, organic-inorganic compound fertilizers and their preparation, and can solve the problems of burning seeds or seedlings and easily generating heat without the preparation method of organic-inorganic compound fertilizers for grapes. To achieve the effect of avoiding the nutritional insufficiency of inorganic fertilizers, reasonable nutrient distribution ratio and improving grape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

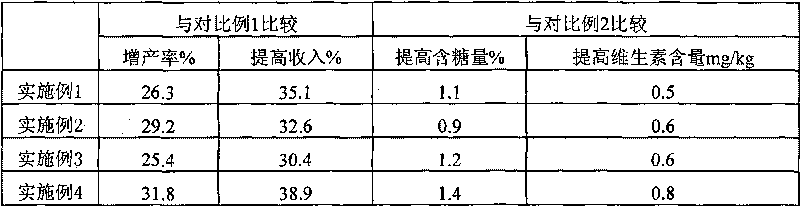

Examples

Embodiment 1

[0054] (1) Preparation of microbial fermentation inoculant:

[0055] 10 parts of horse manure, 85 parts of edible fungus slag, 2.0 parts of ammonium nitrate, 1.5 parts of potassium dihydrogen phosphate, 1.5 parts of magnesium sulfate, mix well, adjust the moisture content to 60%wt%, pH value 7.2, cover with plastic film, stack Make fermentation, wait until the temperature of the pile rises to 50°C, keep it for 7 days, turn over the pile, and ferment for another 5 days. Obtain solid microbial fermentation inoculum.

[0056] (2) Preparation of fermented organic fertilizer:

[0057] 70 parts of edible fungus dregs, 20 parts of soybean meal, and 10 parts of solid microbial fermentation agent are fully mixed and uniform. The water content of the mixture was adjusted to be 62%, the C / N was 27 mass ratio, and the pH was 7.1. Pile the above mixture into a trapezoidal pile with a height of 1.5 meters, punch holes from the top down, with 10 holes per square meter, cover with a plastic ...

Embodiment 2

[0061] (1) Preparation of microbial fermentation inoculant:

[0062] 20 parts of horse manure, 75 parts of edible fungus slag, 1.0 part of ammonium nitrate, 2 parts of potassium dihydrogen phosphate, 2 parts of magnesium sulfate, mix well, adjust the moisture content to 65% wt%, pH value 7.5, cover with plastic film, stack Make fermentation, wait until the temperature of the pile rises to 50°C, keep it for 5 days, turn over the pile, and ferment for another 7 days. Obtain solid microbial fermentation inoculum.

[0063] (2) Preparation of fermented organic fertilizer:

[0064] 60 parts of edible fungus dregs, 15 parts of soybean meal, and 15 parts of solid microbial fermentation agent are fully mixed and uniform. Adjust the moisture content of the mixture to be 58%, C / N to be 25, and pH 7.5.

[0065] Pile the above-mentioned mixed materials into a trapezoidal pile with a height of 1.8 meters, punch holes from the top down, the number of holes per square meter is 15, cover wi...

Embodiment 3

[0068] The preparation of microbial fermentation agent and fermented organic fertilizer is the same as in Example 1, except that the raw material formula of special organic-inorganic compound fertilizer is: 53 parts of fermented organic fertilizer, 14 parts of crushed 80 mesh urea, 8 parts of diammonium phosphate, potassium sulfate 20 parts, 4 parts of magnesium sulfate, 0.6 parts of zinc sulfate, 0.4 parts of boric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com