Aromid fiber blend yarn and processing method thereof

A kind of technology of aramid fiber and processing method, applied in spinning machine, fiber processing, open-end spinning machine, etc., can solve the problem of easy clogging of nozzles of air-jet spinning equipment, affecting the performance of fabrics, and large shrinkage of yarn in boiling water, etc. problems, to achieve good wear resistance, good electrical insulation properties, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Specifications: 21S aramid fiber blended yarn.

[0020] Blending ratio: antistatic synthetic fiber (polyester) 2%, aramid fiber 33%, acrylic fiber 65%.

[0021] Fiber length: 51MM.

[0022] Uses: Yarn for woven fabrics, as protective clothing for workers in electric welding places.

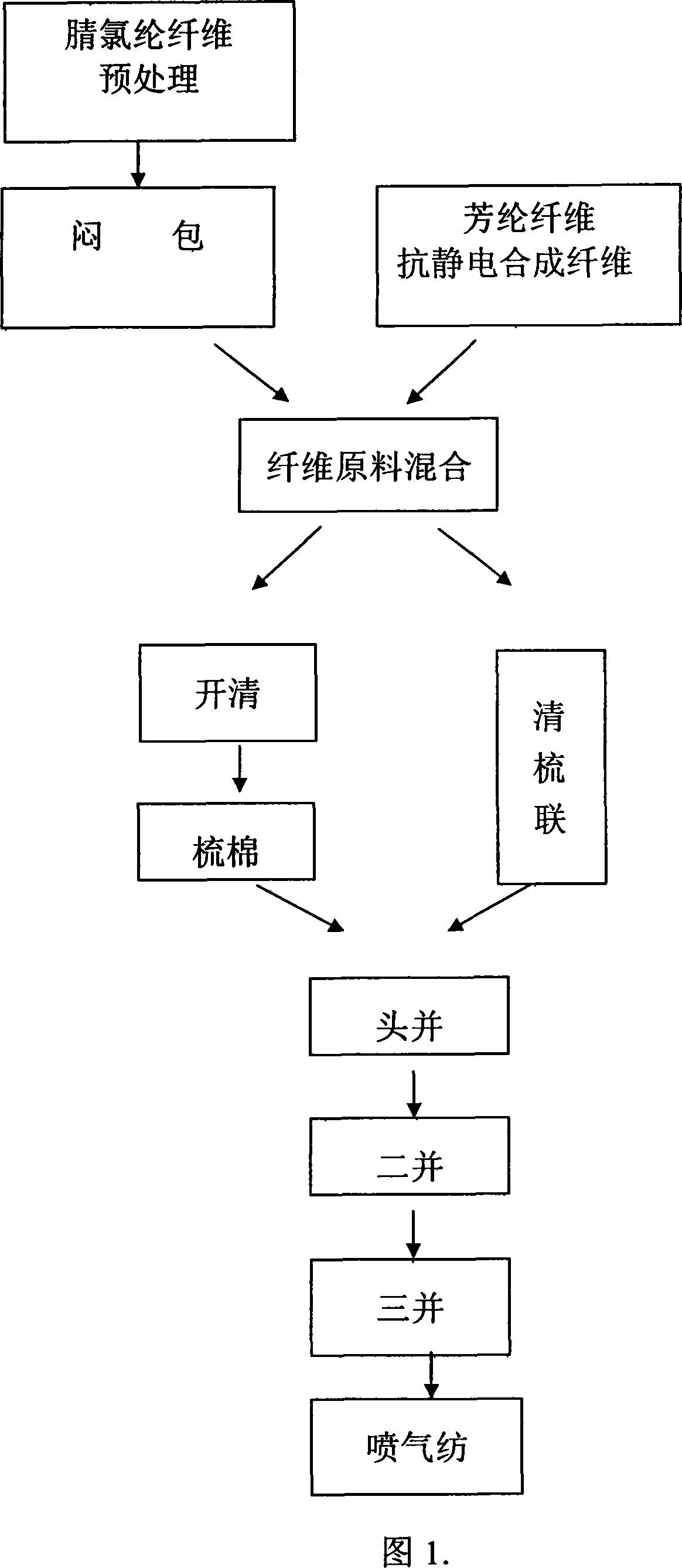

[0023] The production process is shown in Figure 1. Spray the acrylic fiber fiber with the antistatic agent solution of concentration 5% (weight) first and carry out pretreatment, and the solution spraying amount is 10% of fiber weight, and stuffy bag is piled up for 24 hours after packing, then with antistatic synthetic fiber and aramid fiber Mix raw materials according to the blending ratio; after opening and cleaning (A200 cotton grabbing machine—→A006B cotton box blending machine—→A036 cotton opener—→A092A cotton box feeding machine—→A076C single beater lapping machine) —→A186D carding machine—→A272 type drawing frame head paralleling—→A272 type drawing frame two paralleling—→A272 ty...

Embodiment 2

[0025] Specifications: 28S aramid fiber blended yarn.

[0026] Blending ratio: antistatic synthetic fiber (acrylic fiber) 4%, aramid fiber 46%, acrylic fiber 50%.

[0027] Fiber length: 38MM.

[0028] Uses: Yarn for woven fabrics, fabrics for home decoration curtains.

[0029] The production process is shown in Figure 1. Spray the acrylic fiber with the antistatic agent solution of concentration 8% (weight) earlier and carry out pretreatment, and the solution spraying amount is 15% of fiber weight, stuffy bag is piled up for 24 hours after packing, then with antistatic synthetic fiber and aramid fiber Mix raw materials according to the blending ratio; after opening and cleaning (A200 cotton grabbing machine—→A006B cotton box blending machine—→A036 cotton opener—→A092A cotton box feeding machine—→A076C single beater lapping machine) —→A186D carding machine—→A272 type drawing frame head paralleling—→A272 type drawing frame two paralleling—→A272 type drawing frame three parall...

Embodiment 3

[0031] Specifications: 40S aramid fiber blended yarn.

[0032] Blending ratio: antistatic synthetic fiber (acrylic fiber) 3%, aramid fiber 62%, acrylic fiber 35%. Fiber length: 51MM.

[0033] Uses: Yarn for woven fabrics, home decoration curtain fabrics, home decoration fabrics for high temperature occasions.

[0034] Production process: first spray the acrylic fiber with a concentration of 10% (weight) antistatic agent solution for pretreatment, the spraying amount of the solution is 20% of the weight of the fiber, pack it and stack it for 24 hours, and then mix it with the antistatic synthetic fiber and aramid fiber according to the blending ratio for raw materials mixing, through the cleaning and carding unit (A006C cotton grabbing machine—→TF30 heavy object separator—→FA103 double-axis flow cotton opener—→FA028A multi-compartment blending machine—→FA111A single hand cleaning Cotton machine—→FA151 dust removal machine—→ZFA177A feeding box—→FA221B carding machine)—→FA311 typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com