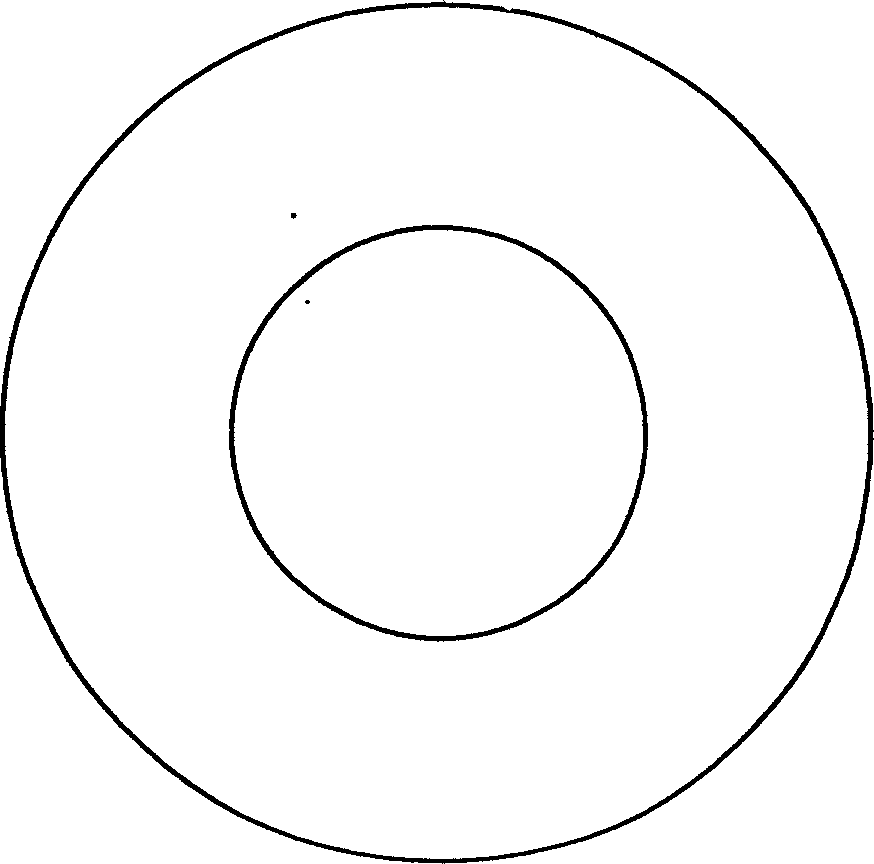

Cubic boron nitride ceramic binder parallel abrasion wheel and its production method

A vitrified bond and cubic boron nitride technology, which is applied in the field of cubic boron nitride vitrified bonded parallel grinding wheels, can solve problems such as difficult roughness requirements, low grinding tool processing efficiency, and high compressor noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

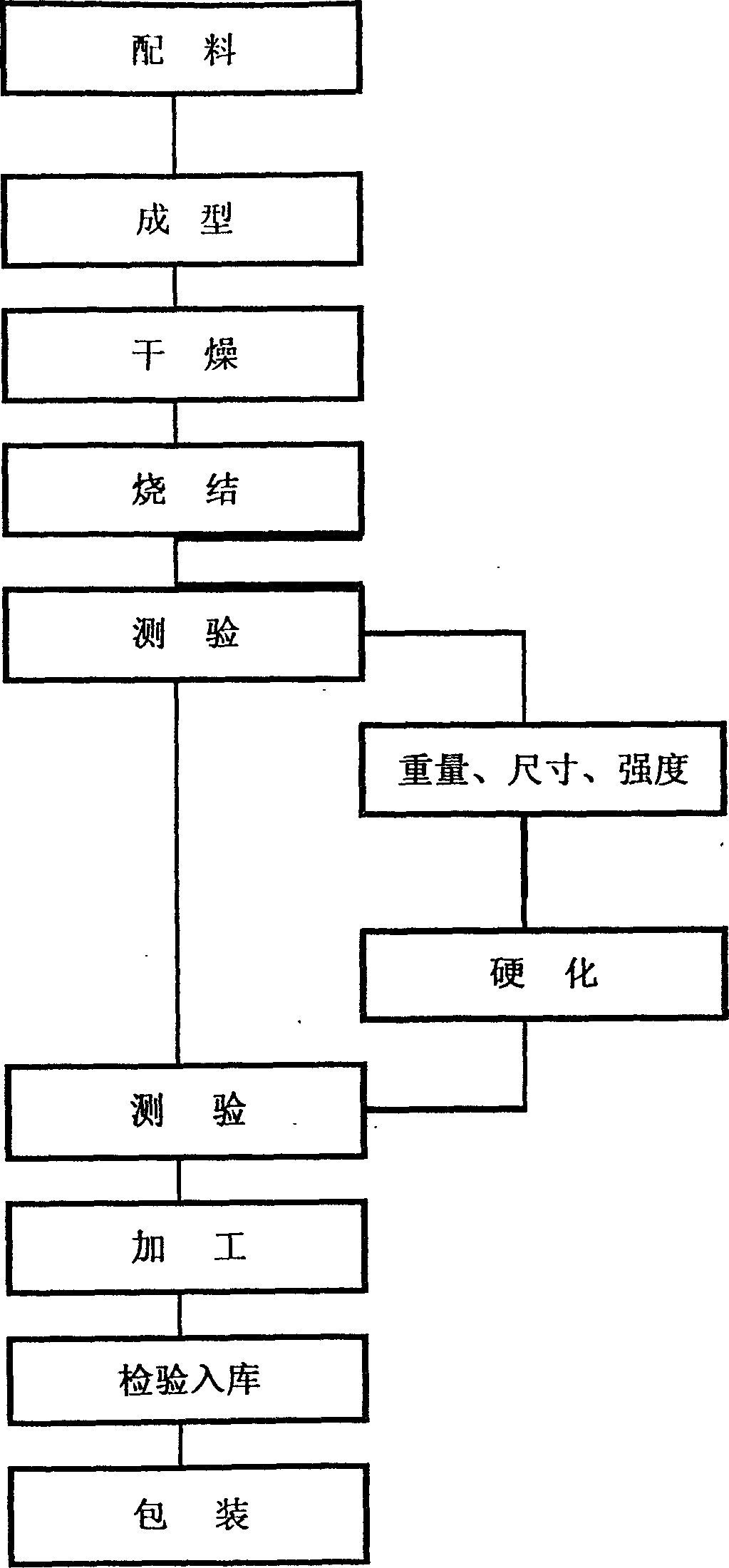

[0007] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0008] According to the above three technical solutions, the cubic boron nitride ceramic bond parallel grinding wheel of the present invention is calculated by weight percentage:

[0009] Cubic boron nitride 44.05%, dextrin powder 1.76%, white corundum 33.04%, wetting agent 3.97%, ceramic bond 17.18%, the total amount is 100%.

[0010] For example, the density is 2.270 / cm 3 , The volume is 37cm 3 The grinding wheel is made of a mixture of 37g cubic boron nitride, 1.48g dextrin powder, 27.75g white corundum, 3.33g wetting agent, and 14.43g ceramic bond for a total of 83.99g.

[0011] The ceramic bonding agent is silicon oxide or aluminum oxide or lithium oxide or magnesium oxide; the wetting agent is prepared by adding 1 g of dextrin powder to every 200 g of water. Cubic boron nitride is a commercially available new type of super-strength wear-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com