Method for producing high-purity concentrated hydrochloric acid by adopting hydrogen chloride gas containing chlorosilane

A hydrogen chloride gas, concentrated hydrochloric acid technology, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride and other directions, can solve the problems of easy blockage of the absorber circulating pump and pipeline, inability to use analytical recovery, and inability to run for a long time, to reduce HCl emissions, The effect of increasing production stability and operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

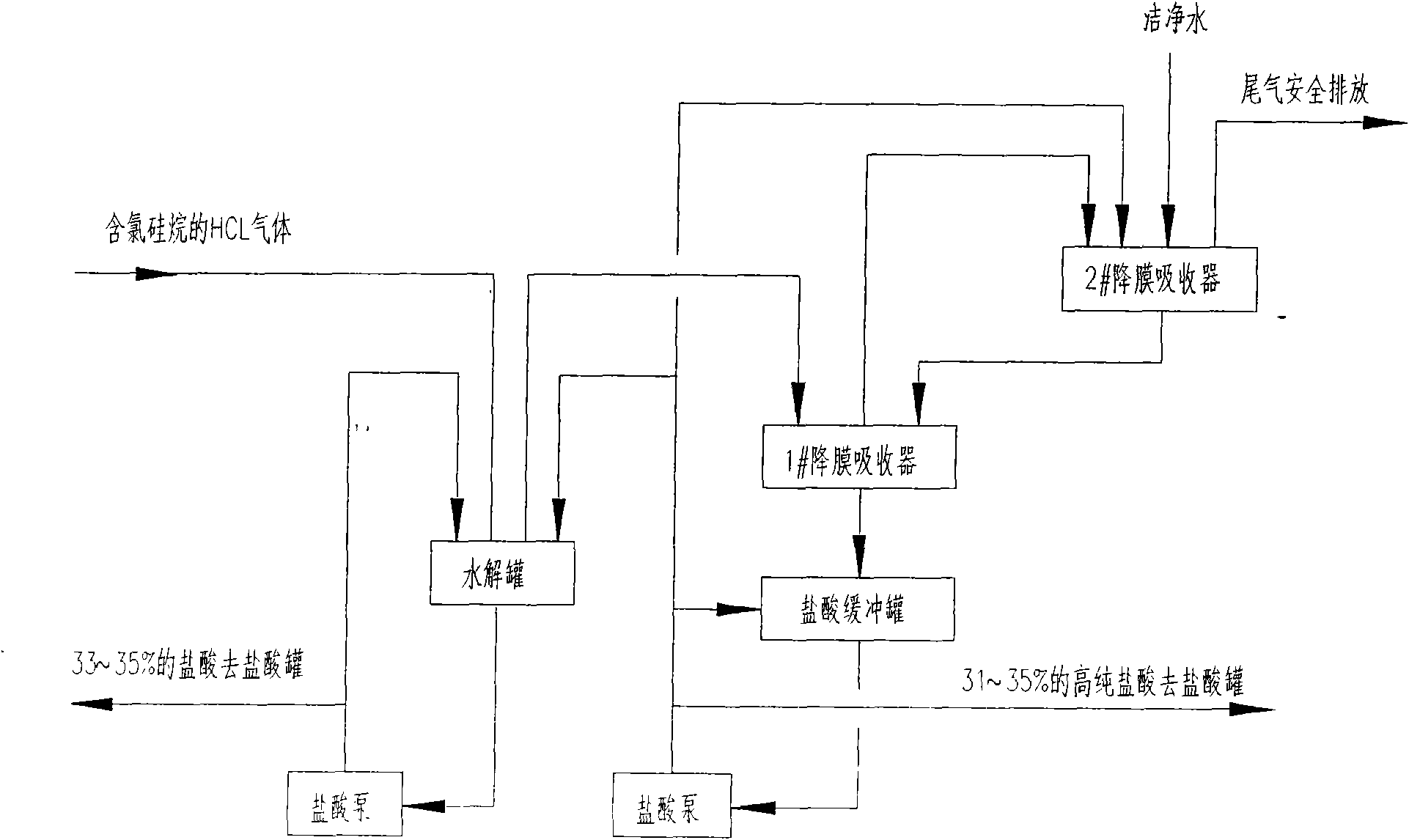

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] The main equipment is as follows:

[0027] 1) Two hydrolysis tanks, one open and one ready (beneficial for regular cleaning of silica gel), are made of carbon steel inner glass-lined and carbon steel cooling water jacket, which mainly play the role of anti-corrosion and cooling. A gas distributor of PTFE material is arranged in the hydrolysis tank.

[0028] 2) Two series falling film absorbers (1# and 2#, with absorption and cooling function), the material is carbon steel plus graphite.

[0029] 3) 4 fluoroplastic circulating pumps (both open and ready) and a finished hydrochloric acid buffer tank (made of carbon steel and glass-lined inside)

[0030] The HCl tail gas containing chlorosilane first enters the hydrolysis tank, and is evenly distributed in the hydrolysis tank by the gas distributor in the hydrolysis tank. It can be directly passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com