Order-driven Single-piece small-batch combined flow production method for processing workshop

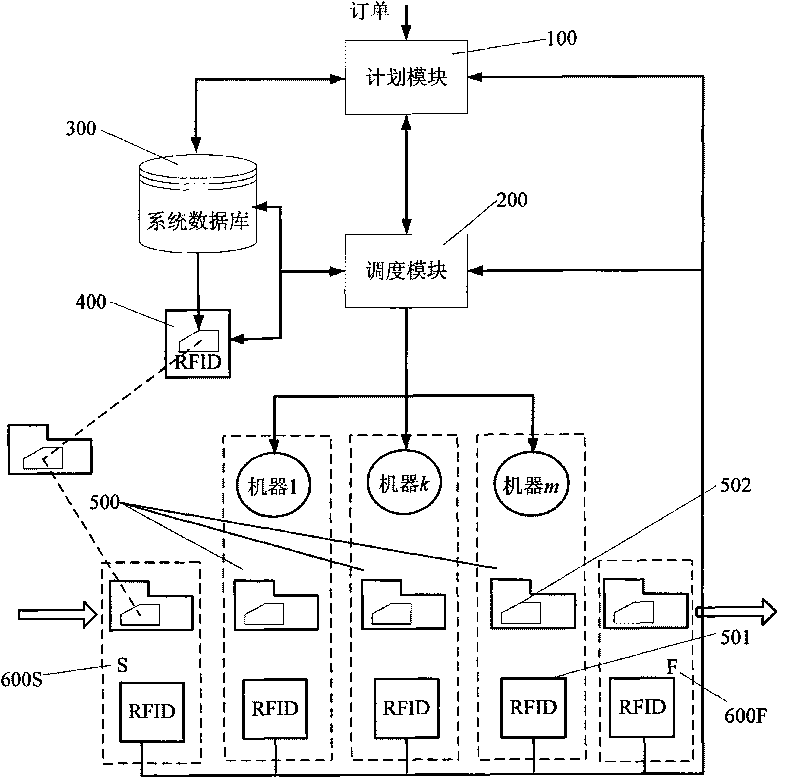

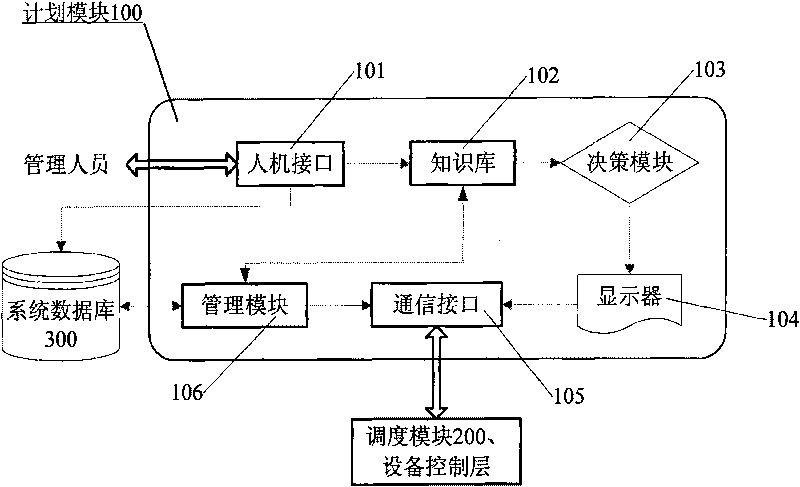

A technology for processing workshops and production methods, applied to computer parts, collaborative devices, instruments, etc., can solve problems such as difficulty in parts distribution, lack of effective integration of information resources, and inability to locate and track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Example 1: Production example of 6 workpieces and 6 machines

[0096] There is an existing order for 6 workpieces. The order is non-preemptive processing and is processed by 6 machines. The order is processed normally. Each workpiece has the same processing priority. The performance index is the maximum processing completion time.

[0097] 6 workpiece numbers are J 1 , J 2 , J 3 , J 4 , J 5 , J 6 , while the workshop M 1 , M 2 , M 3 , M 4 , M 5 , M 6 A total of 6 machines process these 6 workpieces, and the processing time and processing sequence are shown in Table 1.

[0098] Table 1 embodiment production process data sheet

[0099]

[0100] As can be seen from Table 1, different workpieces J j The process route is different, the sequence of the processes contained in each workpiece is different, and the processing time varies with the processing unit. The processing time matrix T and processing constraint matrix M obtained by decomposing Table 1 are: ...

Embodiment 2

[0118] Example 2: Example of flexible production

[0119] In the flexible Job Shop scheduling problem, the processing paths of different workpieces are uncertain. Once the processing paths of the workpieces are determined, the flexible Job Shop scheduling problem can be transformed into a general Job Shop scheduling problem. Therefore, when solving the flexible Job Shop scheduling, a step-by-step solution method can be used. First, the processing paths of different workpieces are determined, and then the Job Shop scheduling problem is optimized under a certain processing path.

[0120] The determination of the processing path of each workpiece, that is, to determine on which machine each process of each workpiece is processed, belongs to the problem of resource allocation. Under a certain processing path, the scheduling problem of Job Shop belongs to the problem of task or job sequence. Therefore, flexible Job The shop scheduling problem also needs to solve the resource alloca...

Embodiment 3

[0125] Example 3: Insert Rush Order Example

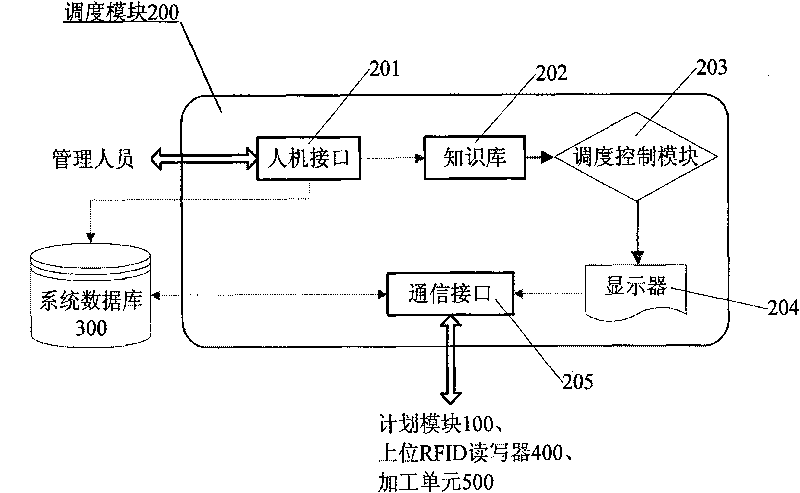

[0126] There is an emergency order, and the planning module 100 evaluates the emergency order and indicates that urgent processing is required. For this purpose, the scheduling priority, process planning and constraints are sent to the scheduling module 200 through its communication interface 105; The urgent order of the planning module 100, according to the information of the parts to be processed and the equipment status information, calls the algorithm of the intelligent algorithm library (such as genetic algorithm) to optimize and decompose the task, generate a scheduling plan and write it into the RFID tag 502; An RFID tag 502 of production information is attached to the urgent workpiece to be processed.

[0127] Assume that 3 artifacts J of normal level are currently in progress i (i=1, 2, 3) 3 machines M k (k=1, 2, 3) flexible machining operations, now an emergency workpiece J with a higher priority needs to be inserted 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com