Industrial production flow prediction method

A prediction method and process technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of relying on manual experience, low standardization, difficult production operation prediction, etc., to solve production problems, improve production efficiency, The effect of improving the level of standardized work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

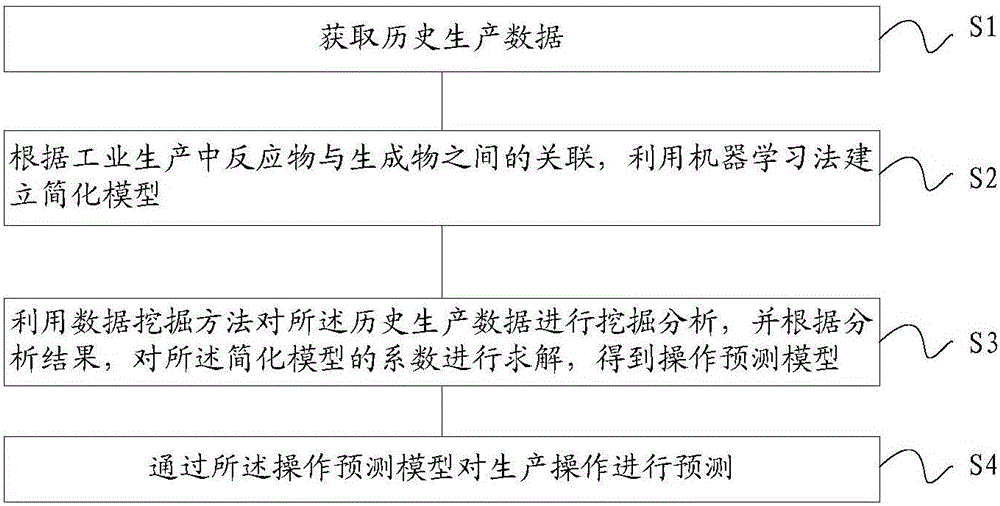

[0059] see figure 1 As shown, a method for predicting an industrial production process provided by an embodiment of the present invention includes:

[0060] S1: Obtain historical production data;

[0061] S2: According to the relationship between reactants and products in industrial production, use machine learning to establish a simplified model;

[0062] S3: Mining and analyzing the historical production data using a data mining method, and solving the coefficients of the simplified model according to the analysis results to obtain an operation prediction model;

[0063] S4: Predict the production operation through the operation prediction model.

[0064] The industrial production process prediction method described in the embodiment of the present invention uses machine learning to establish a simplified model according to the relationship between reactants and products in industrial production; uses data mining methods to mine and analyze historical production data, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com