Double-vertical explosive welding charging method of large-area thin plate

An explosive welding, large-area technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

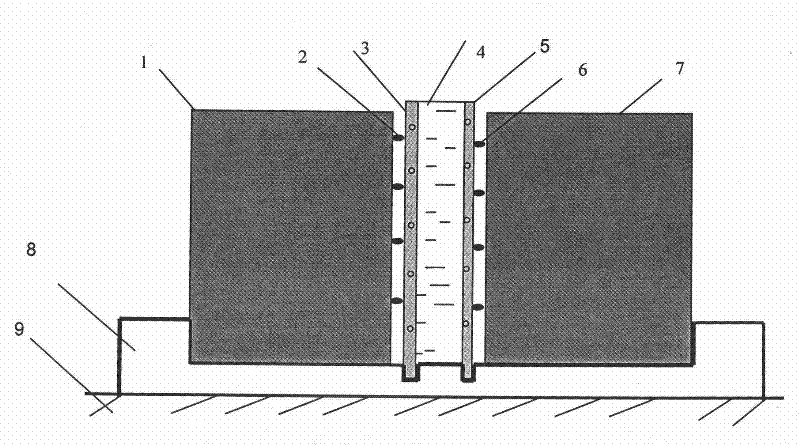

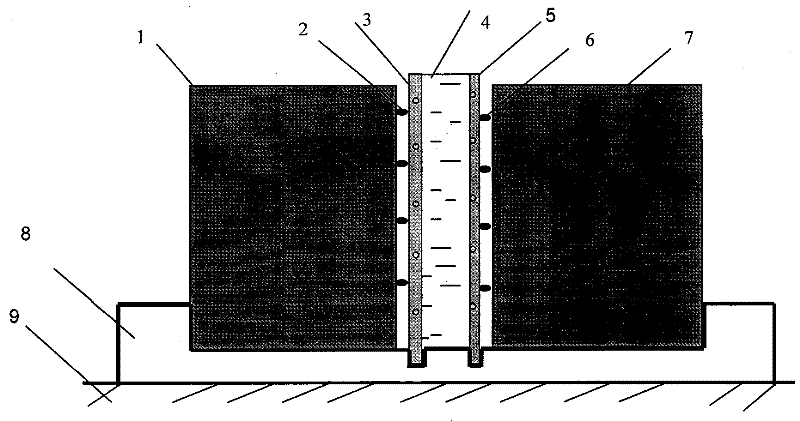

[0026] 1. The doubler plate is 5mm wider than the base plate, the groove depth of the fixed block is 5mm, and the groove width is 2mm.

[0027] 2. The double board is 10mm longer than the base plate, and 5mm is left on each side for drilling and fixing.

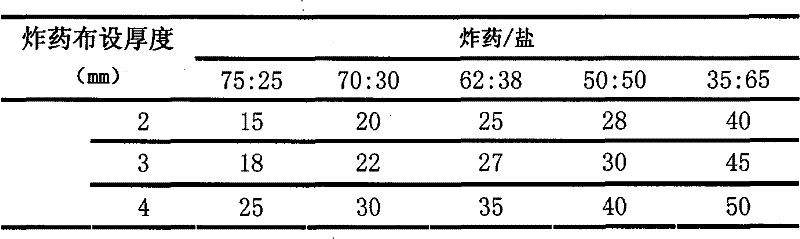

[0028] 3. Use 65# powder as the explosive, and the charge thickness is 4cm, so the distance between the two grooves is 4cm.

[0029] 4. The distance between the base plate and the base plate is 4mm, and the gap is made of stainless steel balls with a diameter of 4mm, which are spot welded on the base plate, so the distance between the two grooves and the two sides of the fixed block is 24mm.

[0030] The final explosive welding composite rate is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com