Continuous metallurgical composite production process for copper-clad aluminum rows

A copper-clad aluminum row and production process technology, which is applied to metal/alloy conductors, metal rolling, electrical components, etc., can solve problems such as uneven shrinkage of rectangular rows, uneven copper layer coverage, and affecting mechanical properties, and achieve continuous Uninterrupted production, saving manpower, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

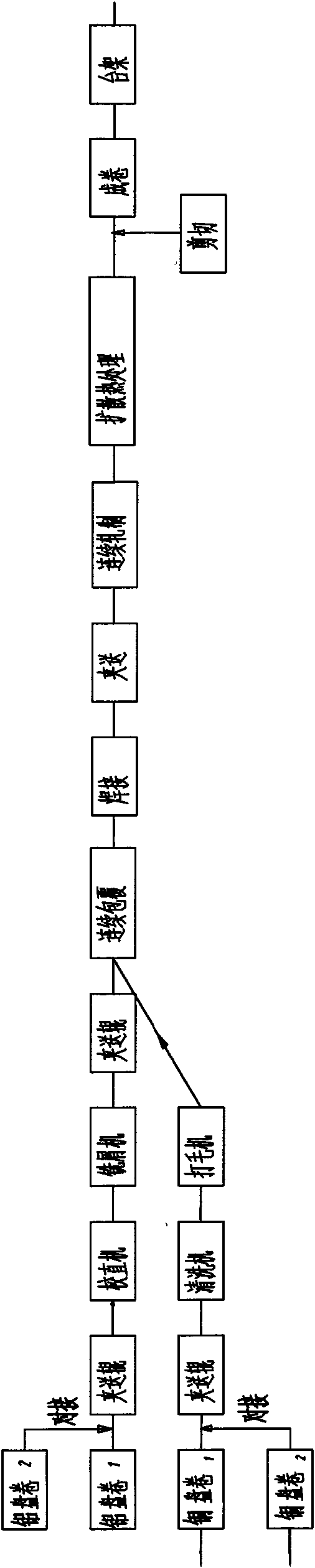

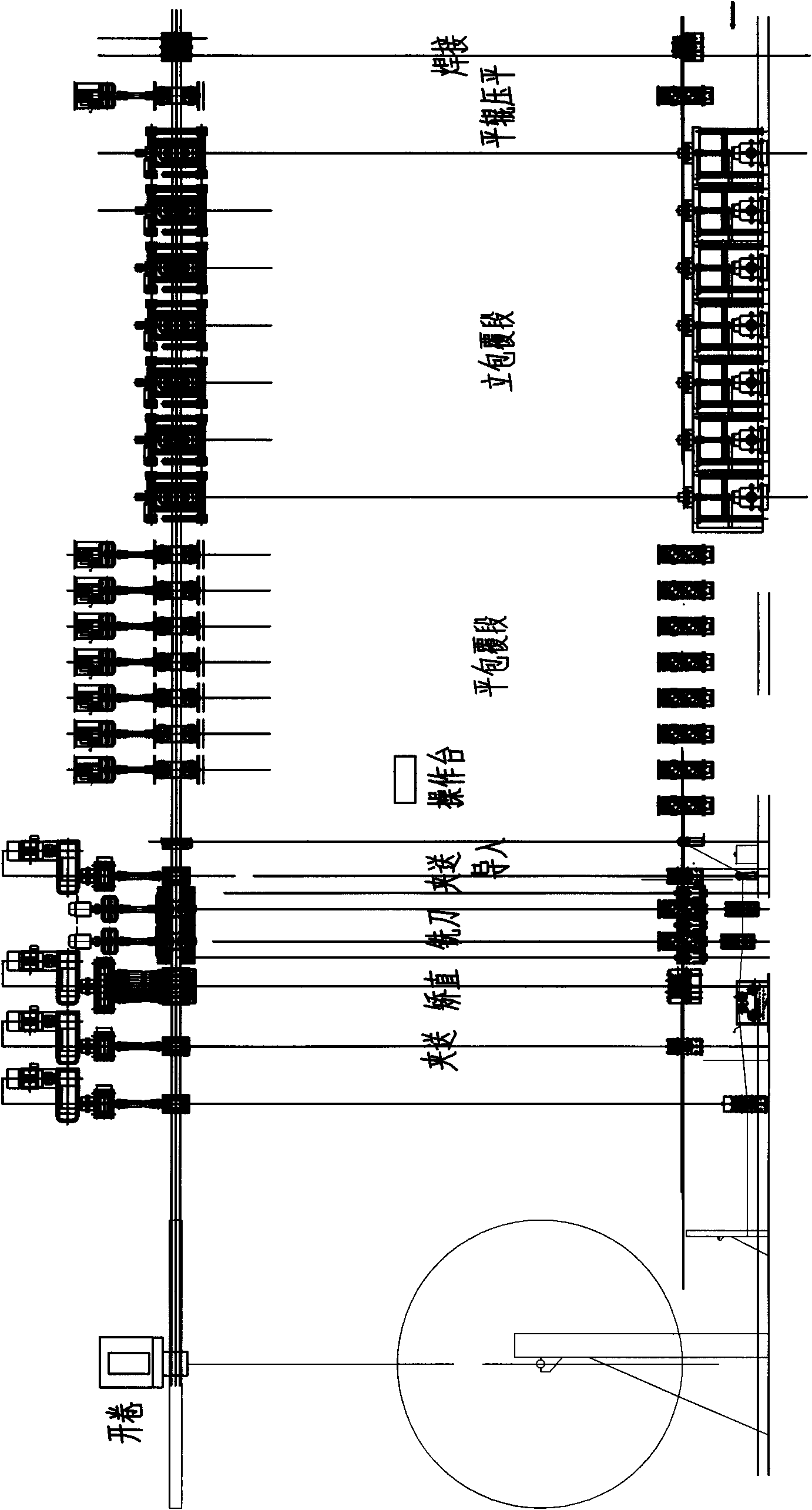

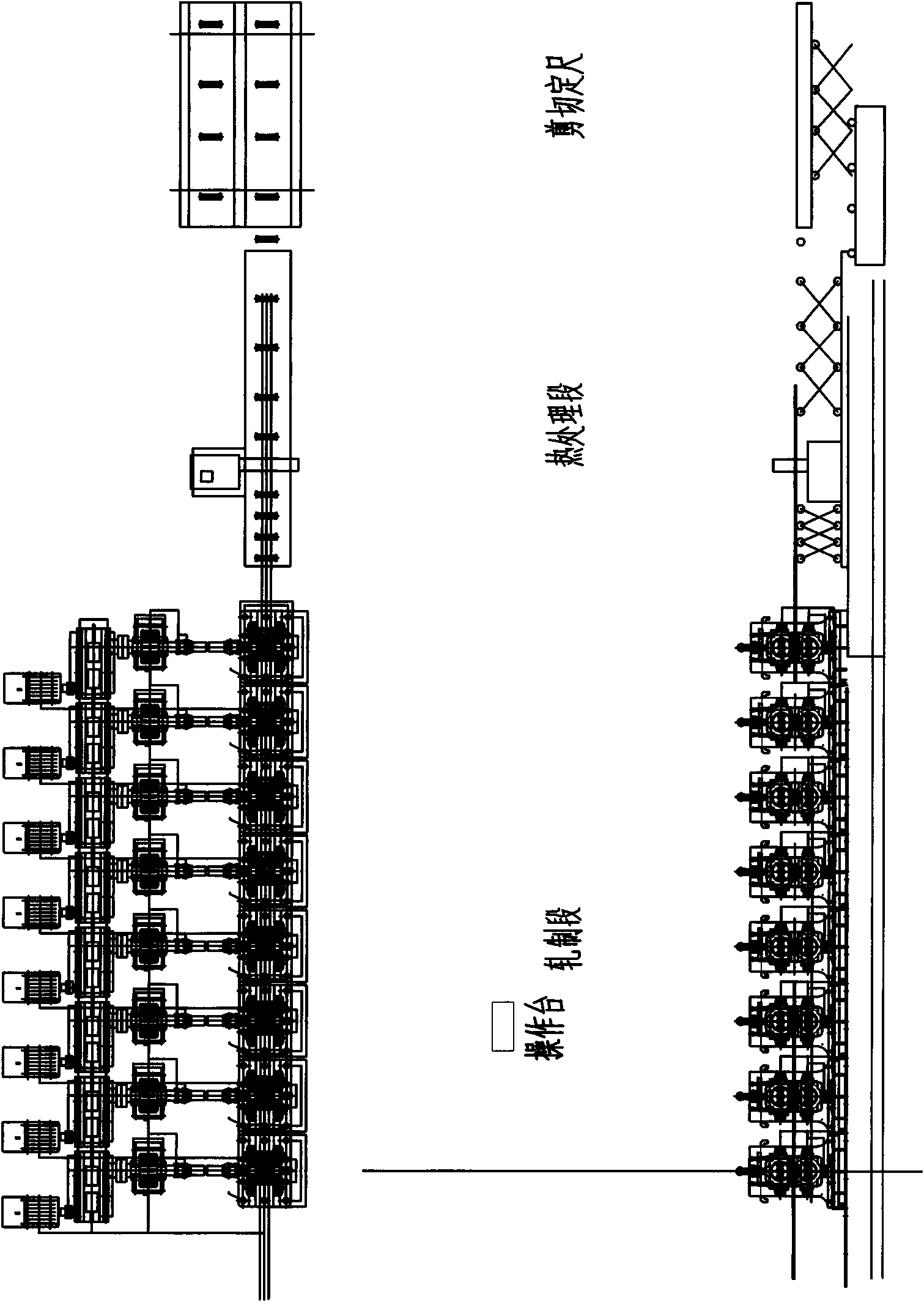

[0035] Taking the small-sized aluminum row blank (below 60*8 mm) as an example, the process flow is as follows figure 1 and shown in Figure 2. First use the coil, before the first coil 1 is used up, the head end of the coil 2 is welded or squeezed to the end of the coil 1, the time required is 3-4min, and the running speed of the whole line is decelerated at this time to 1-2m / min, after the welding is completed, the running speed of the whole line will return to 8-9m / min.

[0036] The docking method of the copper strip is the same as that of the aluminum row. Before the coil 1 of the copper strip is finished, the head end of the copper coil 2 is connected with the end of the copper coil 1 by argon arc welding or extrusion, and the whole line runs The center line is at a height of 1.2m, and the copper skin elevation is below the operating center line. The centerline of the copper skin and the centerline of the aluminum row are in a vertical plane.

[0037] In the role of pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com