Uniform dough cutting mechanism based on cooked wheaten food processing

A cutting mechanism and dough technology, applied in dough forming and cutting equipment, pre-baked dough processing, etc., can solve the problems of pasta sticking knife affecting cutting, manual addition of yeast is cumbersome, and cutting amount cannot be controlled, so as to reduce the processing space, The effect of automatically cutting the dough evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

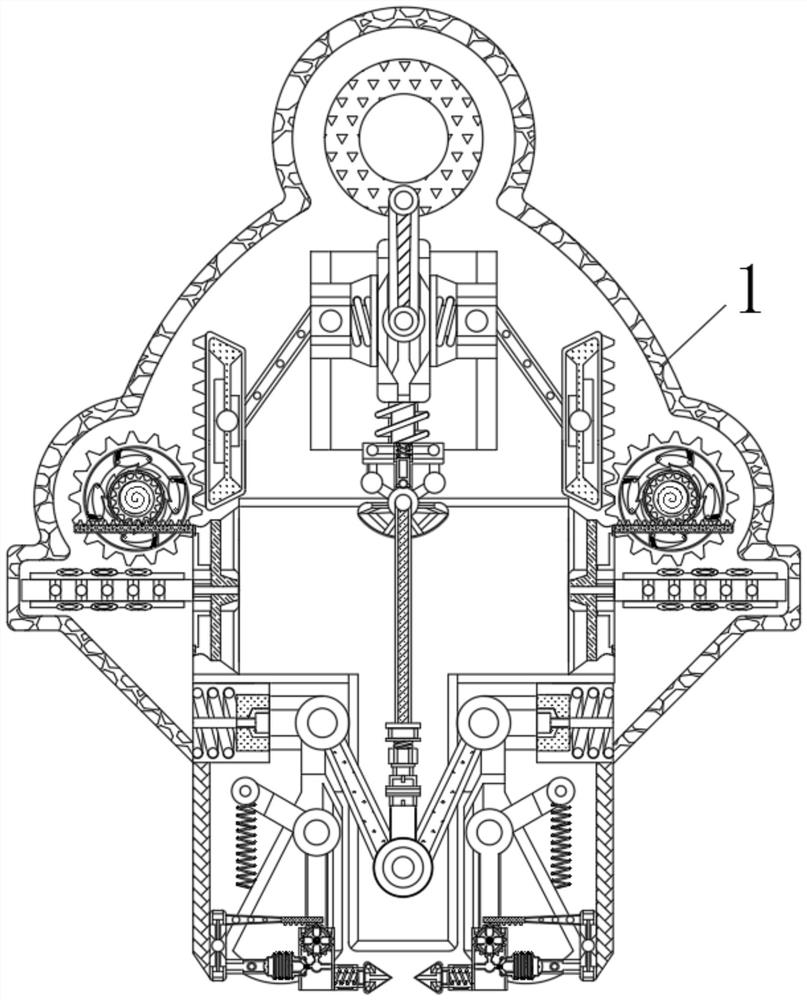

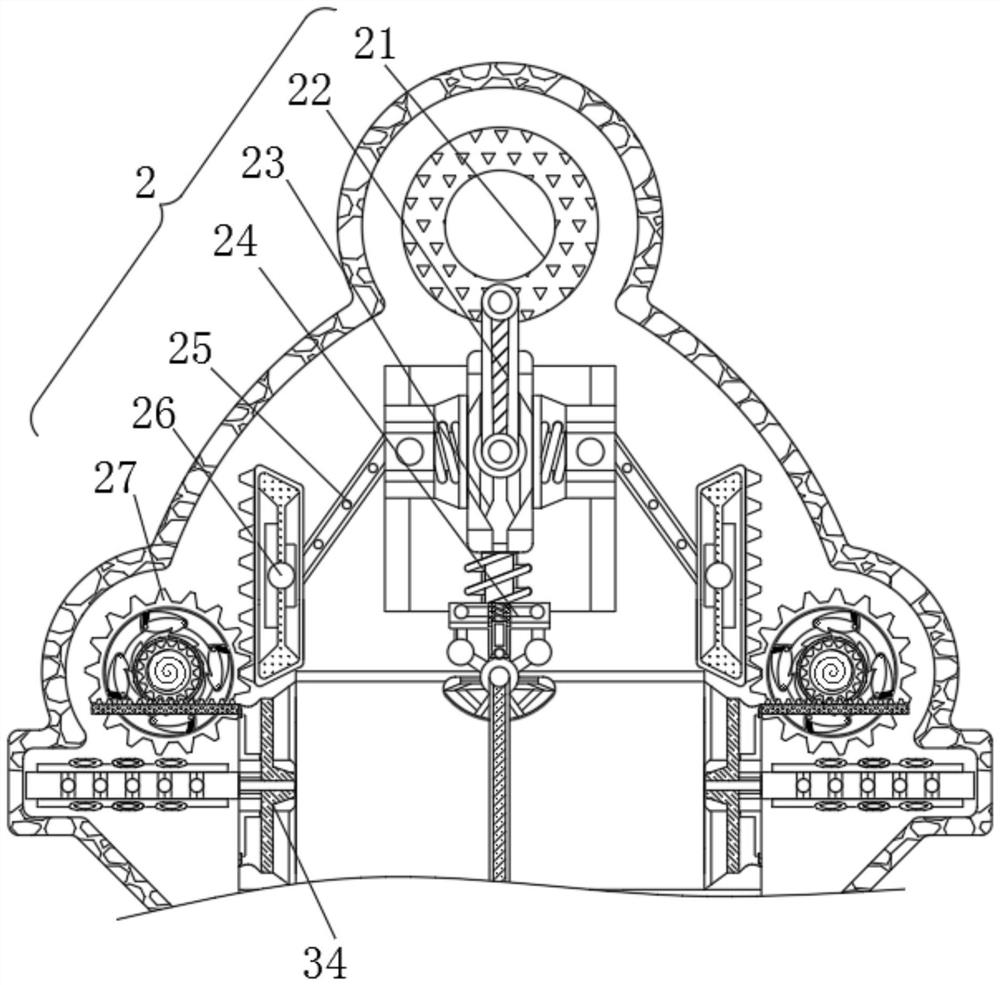

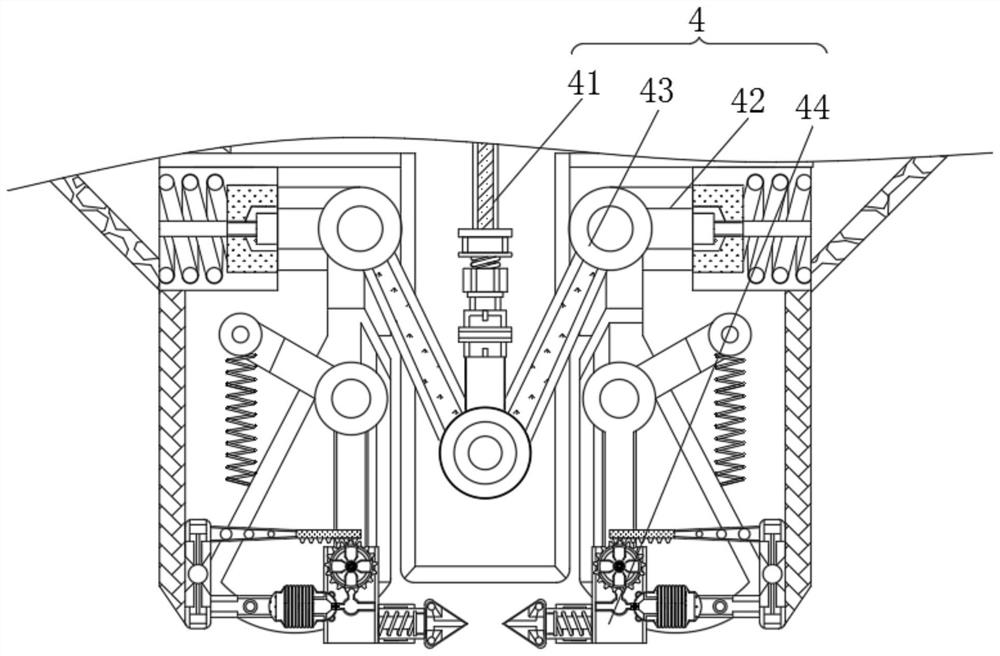

[0028] see figure 1 and figure 2 and image 3 and Figure 5 , a dough evenly dividing mechanism based on pasta processing, including a cutting mechanism 4 and a yeast mechanism 5, the cutting mechanism 4 includes a linkage rod 41, the bottom of the linkage rod 41 is movably connected with a swing cutting rod 43, and the swing cutting rod 43 is away from the linkage rod A linkage slider 42 is movably connected to one end of the linkage slider 41 , a slider spring is fixedly connected to the right side of the linkage slider 42 , and a dough cutter 44 is fixedly connected to the bottom of the linkage slider 42 .

[0029] When the device is used, the driving wheel 21 starts to rotate at this time, the rotation of the driving wheel 21 drives the reciprocating sliding block 23 to move up and down, and the downward movement of the reciprocating sliding block 23 drives the pressing head 24 to move downward, pressing the material. When the head 24 moves downward, the dough is squee...

Embodiment 2

[0033] see Figure 4 and Image 6 and Figure 7 , a dough evenly dividing mechanism based on pasta processing, including a cutting mechanism 4 and a yeast mechanism 5, the cutting mechanism 4 includes a linkage rod 41, the bottom of the linkage rod 41 is movably connected with a swing cutting rod 43, and the swing cutting rod 43 is away from the linkage rod A linkage slider 42 is movably connected to one end of the linkage slider 41 , a slider spring is fixedly connected to the right side of the linkage slider 42 , and a dough cutter 44 is fixedly connected to the bottom of the linkage slider 42 .

[0034] At the same time, during the downward movement of the pressing head 24, due to the reaction force generated by pressing the dough, the reaction spring 51 is compressed, and the reaction spring 51 is compressed, so that the yeast slider 52 squeezes the yeast in the yeast capsule 53, and the yeast capsule The yeast in 53 is squeezed and sprayed into the dough, so as to achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com