Method for machining large-depth-diameter-ratio small hole of glass fiber composite-aluminum alloy layered material

A hole processing method and glass fiber technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as drill bit breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

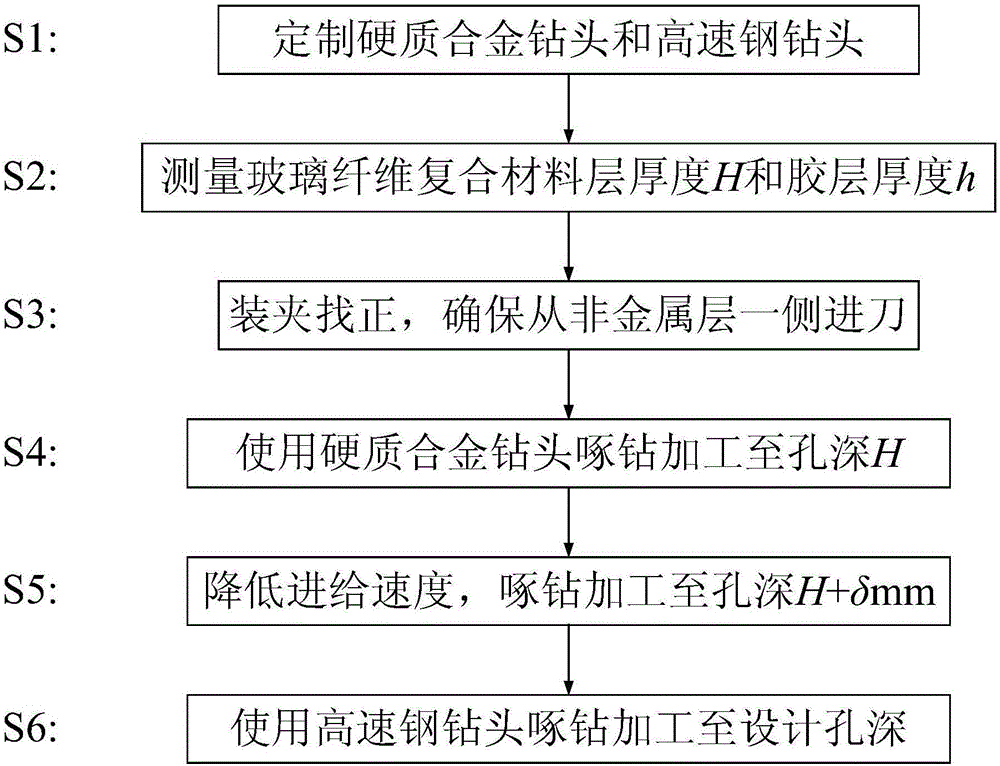

[0025] The workpiece to be processed is a laminated material made of resin-based high-silica glass fiber composite material (thickness 15mm) and forged aluminum 5A06 (thickness 15mm) bonded by epoxy resin adhesive. The theoretical diameter of the hole to be processed is The hole to be processed is a through hole that penetrates the laminated material, the hole depth is 30 mm, and the ratio of depth to diameter is 20. Its processing specific steps are as follows:

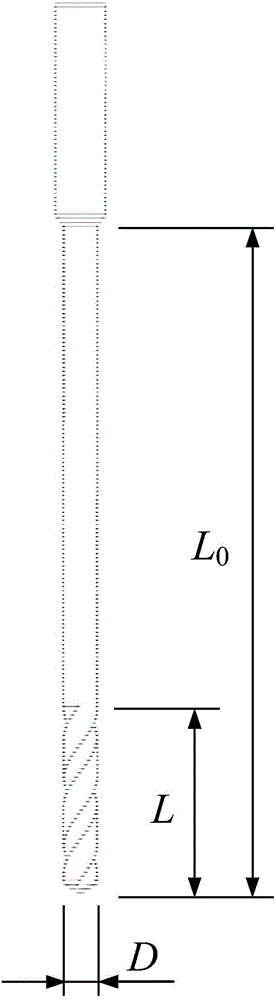

[0026] S1: Prepare tools: According to the size and material characteristics of the workpiece, two special size drills are customized, including: 1) Carbide drills for processing glass fiber composite materials, the diameter of the small diameter of the drill bit is D=1.5mm, and the length of the small diameter blade is L= 10mm, small diameter overall length L 0 = 20mm; 2) High-speed steel drill bit for alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com