Cutting jig for PU panel

A jig and cutting technology, which is applied in the field of mechanical processing, can solve problems such as plate cracking, saw blade deformation, and affecting efficiency, and achieve the effects of cleaning the processing environment, preventing environmental pollution, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

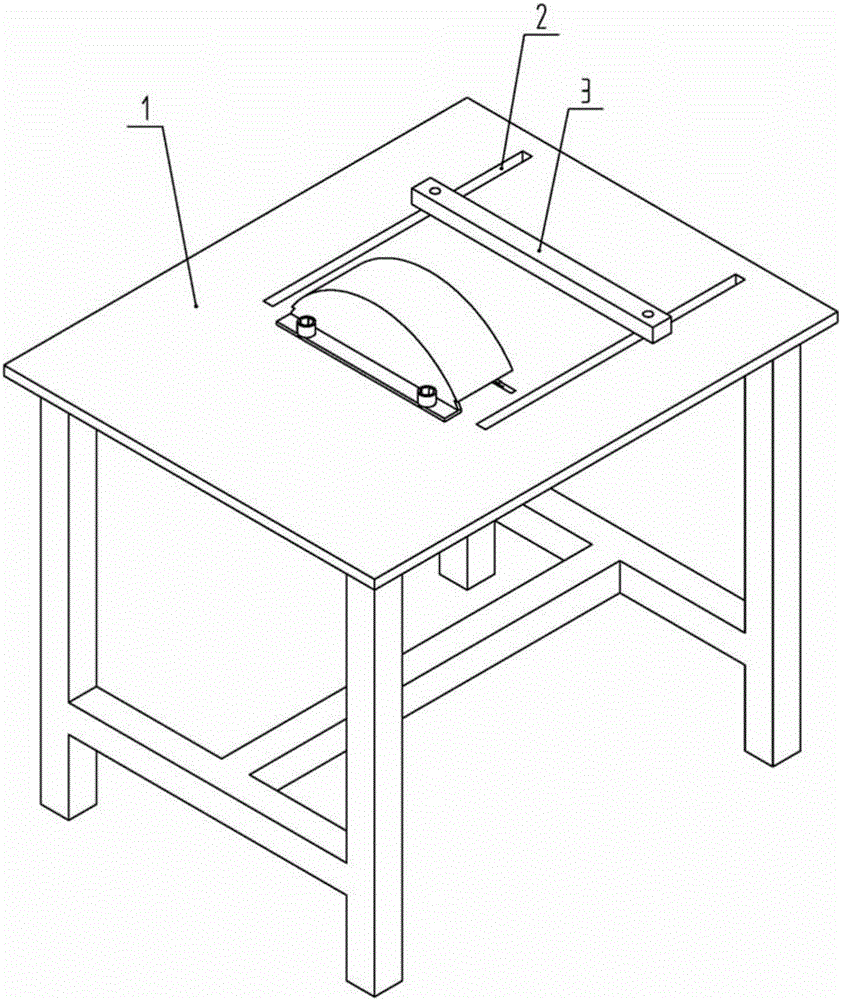

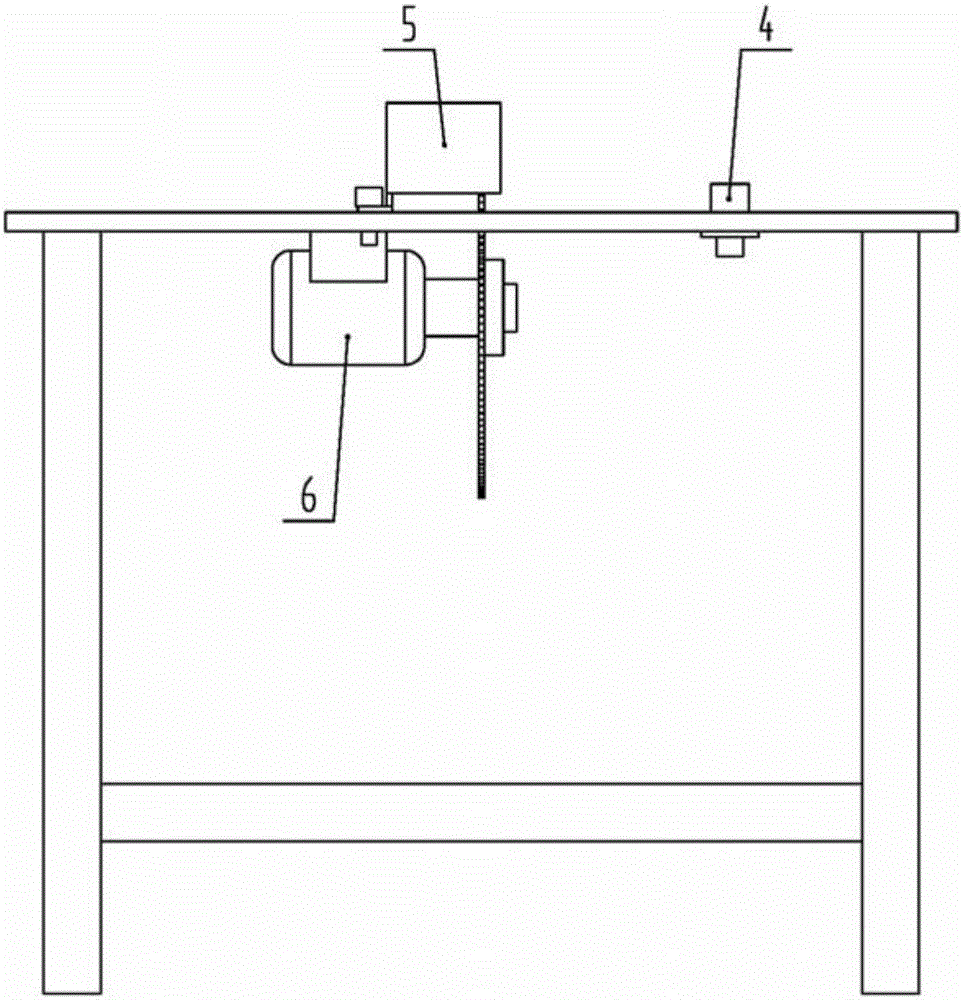

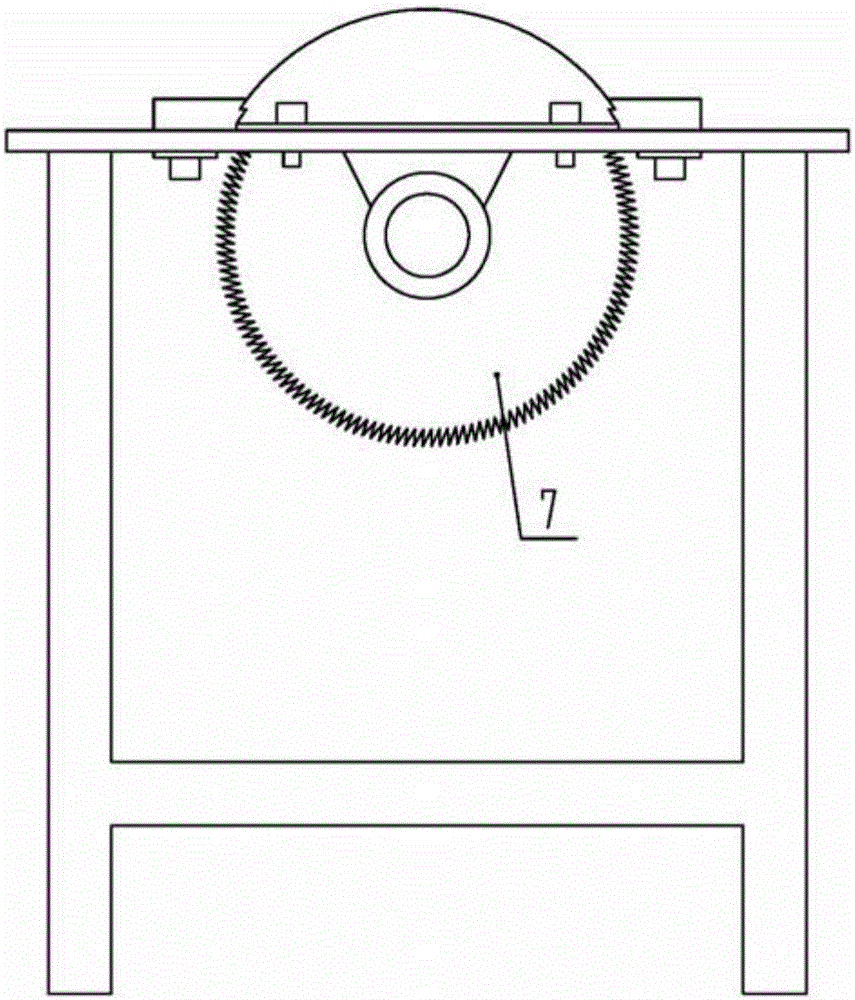

[0025] Such as Figures 1 to 5 As shown, a PU cutting fixture includes a machine platform 1, a driving device 6 installed on the bottom of the machine platform 1, a saw blade 7 installed on the output end of the driving device 6, and a backer capable of sliding on the surface of the machine platform 1. 3, and the dust washing device for dust collection. There is a saw groove on the table of machine 1 that allows the saw blade 7 to protrude. A pair of long grooves 2 perpendicular to the saw blade 7 are provided on the table of machine 1. Guide bolts 4 are installed at both ends of the backing 3, and the backing 3 passes through The guide bolts 4 at both ends are slidingly installed with the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com