Slitting preparation method suitable for hot-melt pre-impregnated filament

A prepreg, hot-melting technology, applied in the field of composite material forming, can solve the problems of splitting, narrowing of the width, and difficulty in achieving high-quality slitting, and achieve the effect of avoiding the narrowing of the width of the tow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

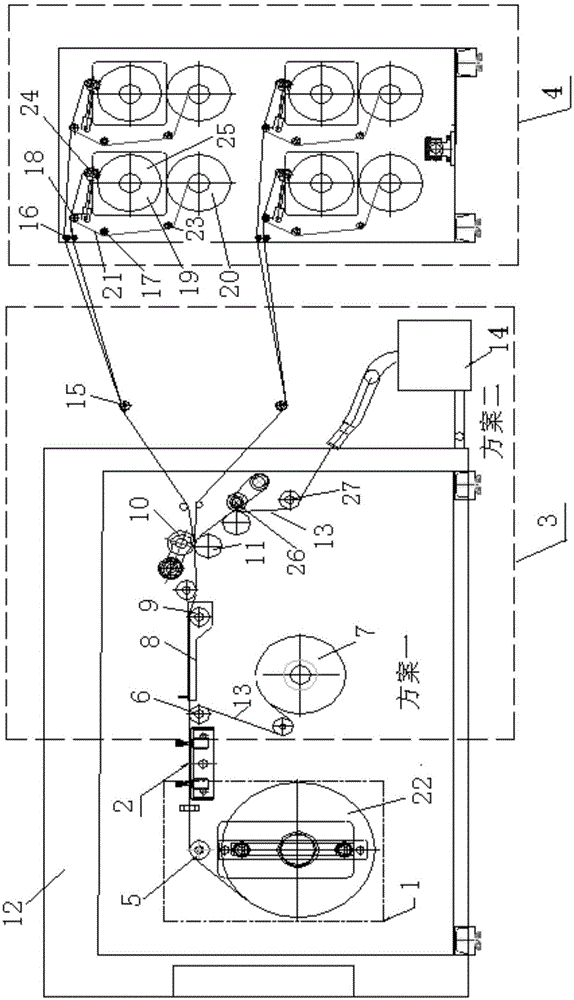

[0017] like figure 1 As shown, a kind of slitting preparation method suitable for high-viscosity hot-melt prepreg according to the present invention, its specific steps are as follows:

[0018] (a) In a low temperature box 12 at 5°C to room temperature (for example: 5°C, 10°C or 25°C), unwind the prepreg tape with paper backing and plastic film from the prepreg tape reel of the unwinding assembly 1 Unwinding at 22, passing through the first guide roller 5, overlapping the hot table 2, and entering the slitting assembly 3 to prepare for slitting;

[0019] (b) In the low-temperature box 12 at 5°C to room temperature (for example: 5°C, 10°C or 25°C), the prepreg tape with paper backing and plastic film passes through the second guide roller 6 of the slitter assembly 3 , separate the paper backing, and the separated paper backing is rewound on the backing winding shaft 7; while the prepreg tape with plastic film continues to pass through the forced cold channel 8, and the prepreg...

Embodiment 2

[0023] like figure 1 As shown, a kind of slitting preparation method suitable for high-viscosity hot-melt prepreg according to the present invention, its specific steps are as follows:

[0024](a) In a low temperature box 12 at 5°C to room temperature (for example: 5°C, 10°C or 25°C), unwind the prepreg tape with paper backing and plastic film from the prepreg tape reel of the unwinding assembly 1 Unwinding at 22, passing through the first guide roller 5, overlapping the hot table 2, and entering the slitting assembly 3 to prepare for slitting;

[0025] (b) In the low-temperature box 12 at 5°C to room temperature (for example: 5°C, 10°C or 25°C), the prepreg tape with paper backing and plastic film passes through the second guide roller 6 of the slitter assembly 3 , continue to pass through the forced cold channel 8, in which the prepreg wire is forcibly cooled to 0°C~5°C (for example: 0°C, 3°C or 5°C); the prepreg tape after forced cooling is flattened The roll 9 is sent to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| winding tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com