Viscous food slicer

A slicing machine and food technology, applied in metal processing and other directions, can solve the problems of slow speed, destroying the flavor of yellow cake, unable to meet the needs of yellow cake, etc., achieving the effect of simple structure and avoiding sticking to the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation, structure, features and functions of the viscous food slicer according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

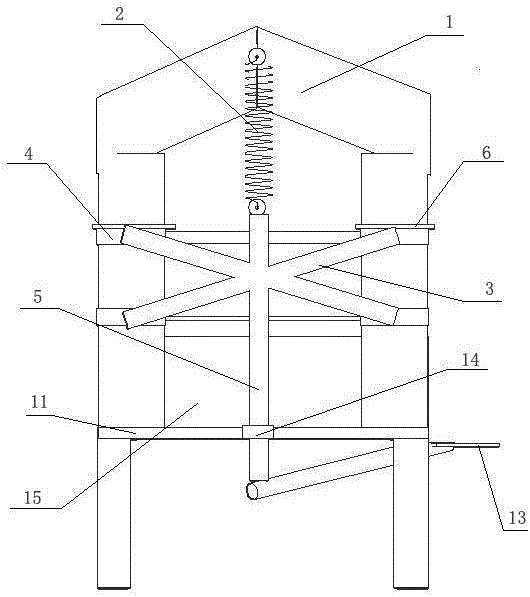

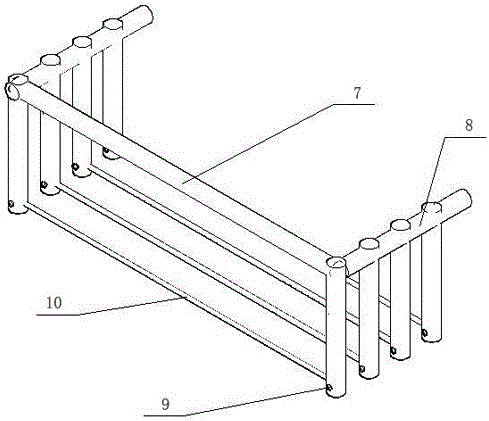

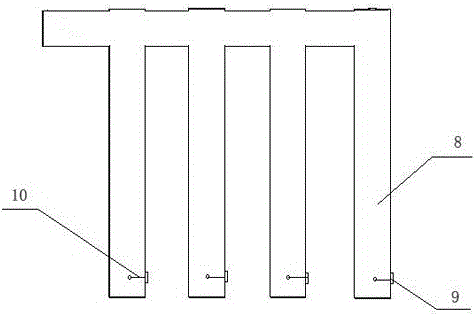

[0023] see Figure 1 to Figure 5 , the viscous food slicer of the present invention comprises a frame 1, a moving support frame 3, a moving sleeve 4, a knife rest 8, a steel wire 10, a corresponding hole 12, and a baffle plate 15, and is characterized in that: the top of the frame 1 passes through in a triangle The two columns are connected, the bottom of the column is connected to the top of the workbench 11, the moving sleeve 4 is installed on the surface of the column of the frame 1, and the position is limited by the limiter 6, the back of the moving sleeve 4 is fixed on the mobile support frame 3, and the return spring 2 is installed At the top of the mobile support frame 3, the other end is connected to the top of the support frame, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com