Fixed-length cutting device for tubular part

A cutting device and part technology, applied in the field of fixed-length cutting devices for tubular parts, can solve the problems affecting the processing of tubular parts, errors, and inability to guarantee the same length of tubular parts, and achieve the effect of improving work efficiency and continuous cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

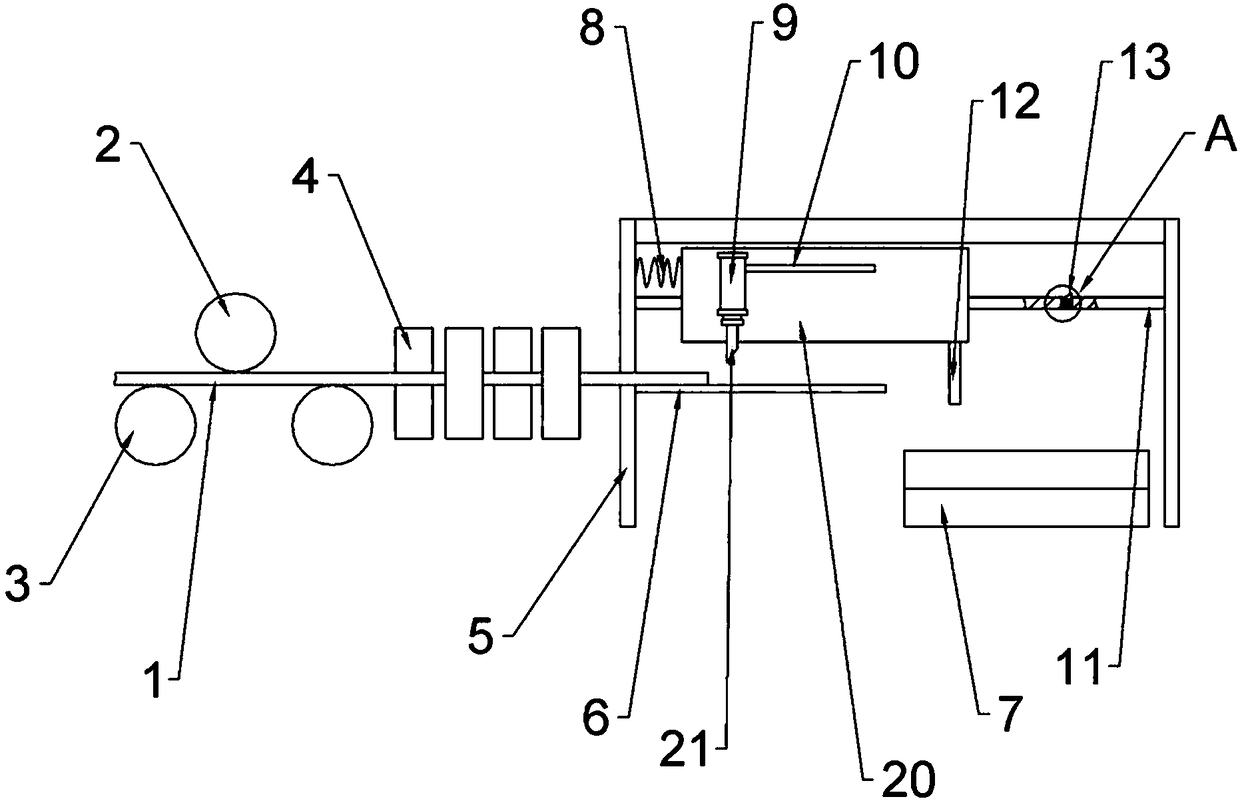

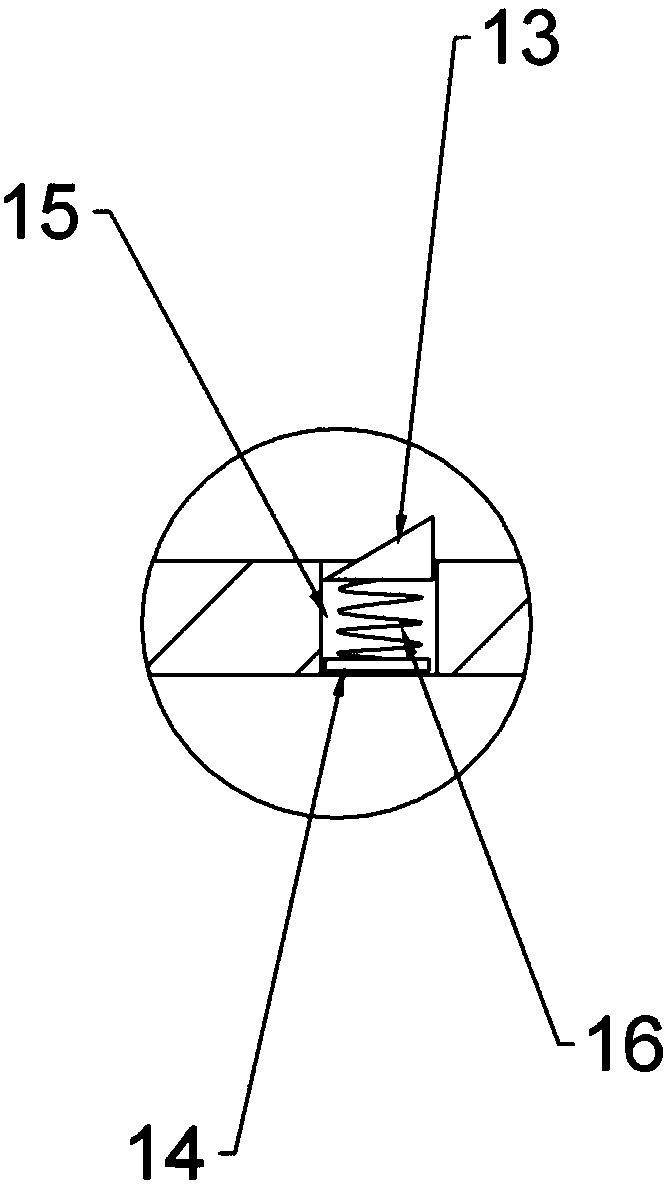

[0021] This embodiment is basically as attached figure 1 and figure 2 Shown: a fixed-length cutting device for tubular parts, including a frame 5, a cutter 21 and a long tube delivery mechanism for delivering the long tube 1, and the long tube delivery mechanism is on one side of the frame 5. The long pipe conveying mechanism includes a plurality of conveying rollers 3 , on which the long pipe 1 is placed to realize transmission, and above the conveying rollers 3 there is also a pressure roller 2 for pressing the long pipe 1 . Cutter 21 is located on frame 5 . A squeeze roller 4 is also arranged between the frame 5 and the long pipe conveying mechanism, and the squeeze roller 4 is used to straighten the long pipe 1 to avoid bending of the long pipe 1 . An elastic member and a slide rail 11 are also provided on the frame 5 , and the elastic member is a spring 8 in this embodiment. The slide rail 11 is slidably connected with a slide seat 20, the slide seat 20 is provided wi...

Embodiment 2

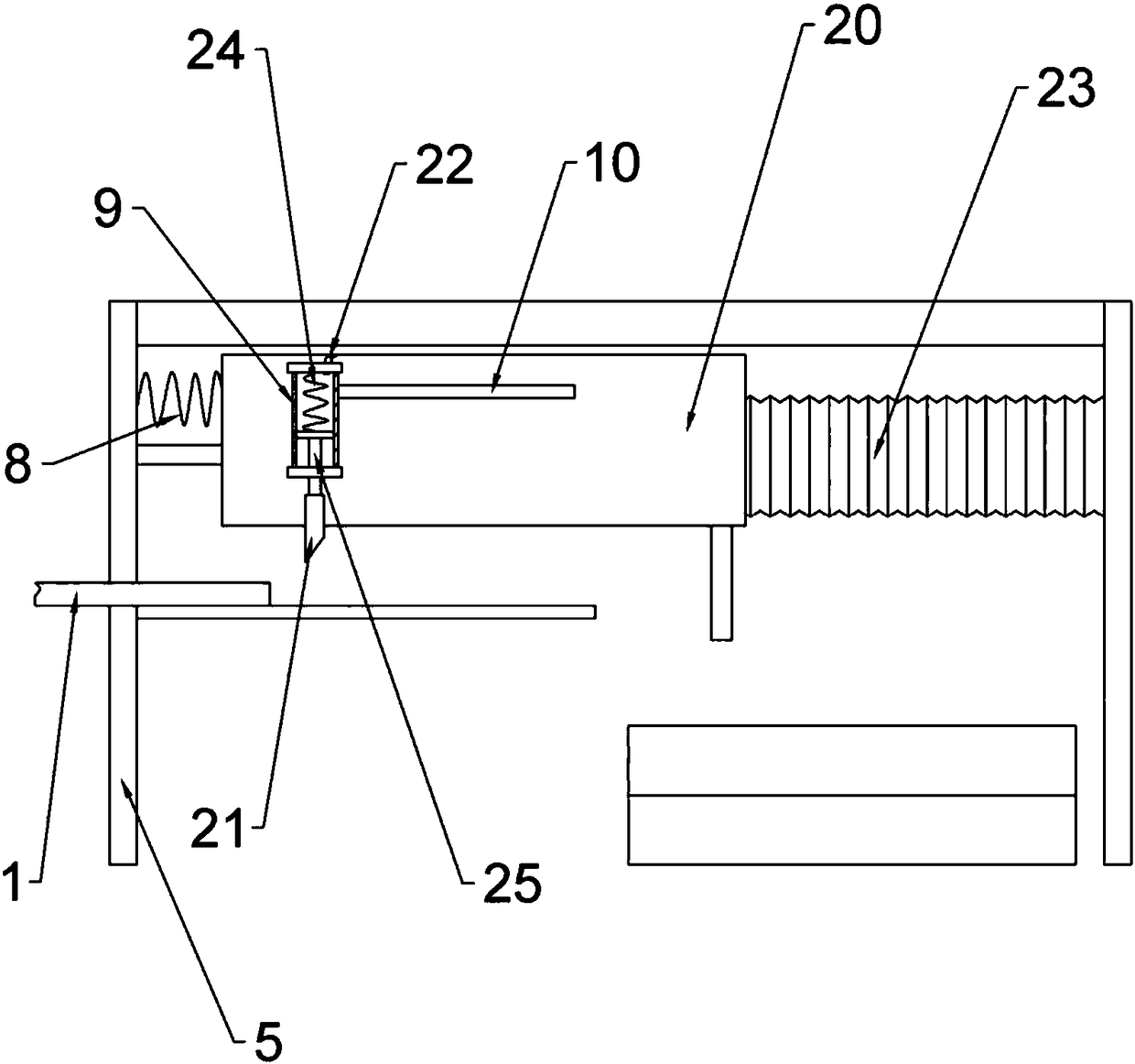

[0025] Such as image 3 and Figure 4As shown, the difference between this embodiment and Embodiment 1 is that it further includes an elastic bellows 23 , one end of the elastic bellows 23 is sealed and fixedly connected with the sliding seat 20 , and the other end is sealed and fixedly connected with the frame 5 . Cylinder 9 comprises cylinder body, and sealing slide is connected with piston in the cylinder body, and piston is provided with piston rod 25, is provided with extension spring 24 on piston and cylinder 9 top walls, and piston rod 25 lower ends are connected with cutter 21. The cylinder body communicates with the elastic bellows 23 through a communication pipe 22 . Because the two ends of the elastic bellows 23 are respectively sealed and fixed to the sliding seat 20 and the frame 5, when the sliding seat 20 slides to the right under the drive of the long tube 1 and the baffle 12, the elastic bellows 23 will be squeezed, The air pressure in the elastic bellows 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com