Packaging box strapping tape automatic removal device and method

A packaging box and automatic technology, which is applied in the field of automatic removal device for packaging box ties, can solve the problems of reducing production efficiency, time-consuming and labor-intensive, etc., and achieve the effects of improving production efficiency, simplifying structure, and continuous cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

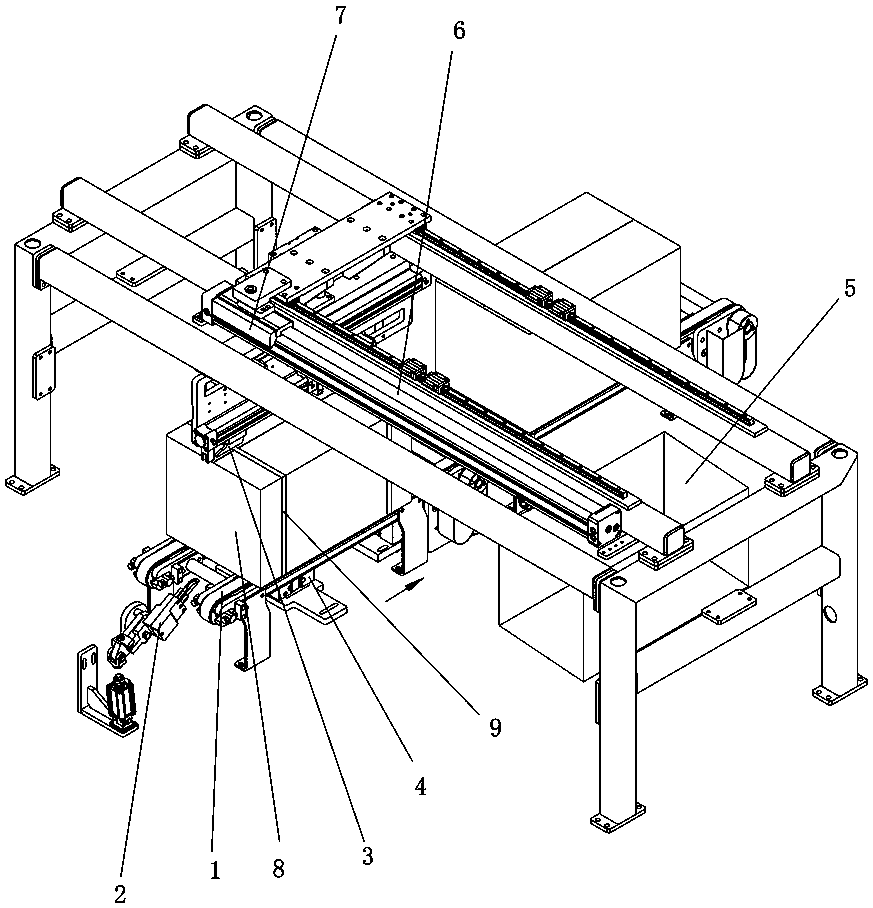

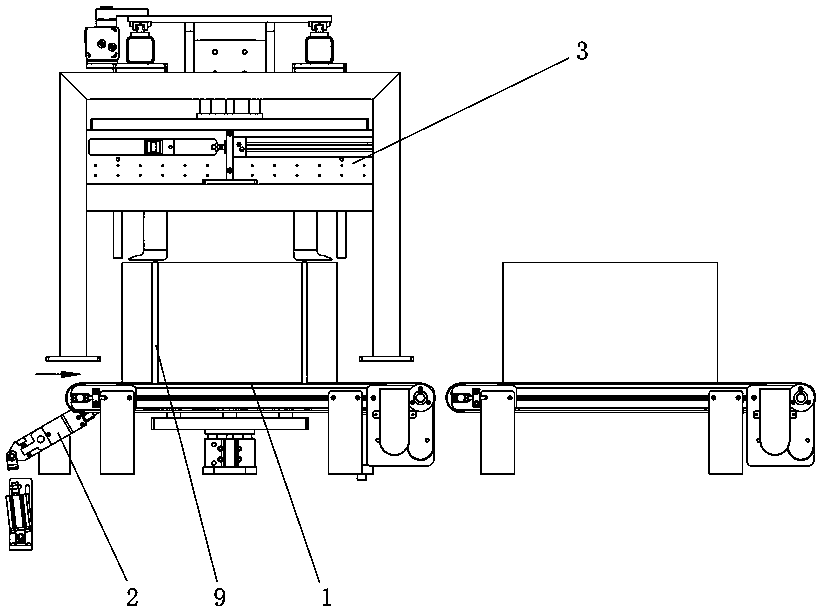

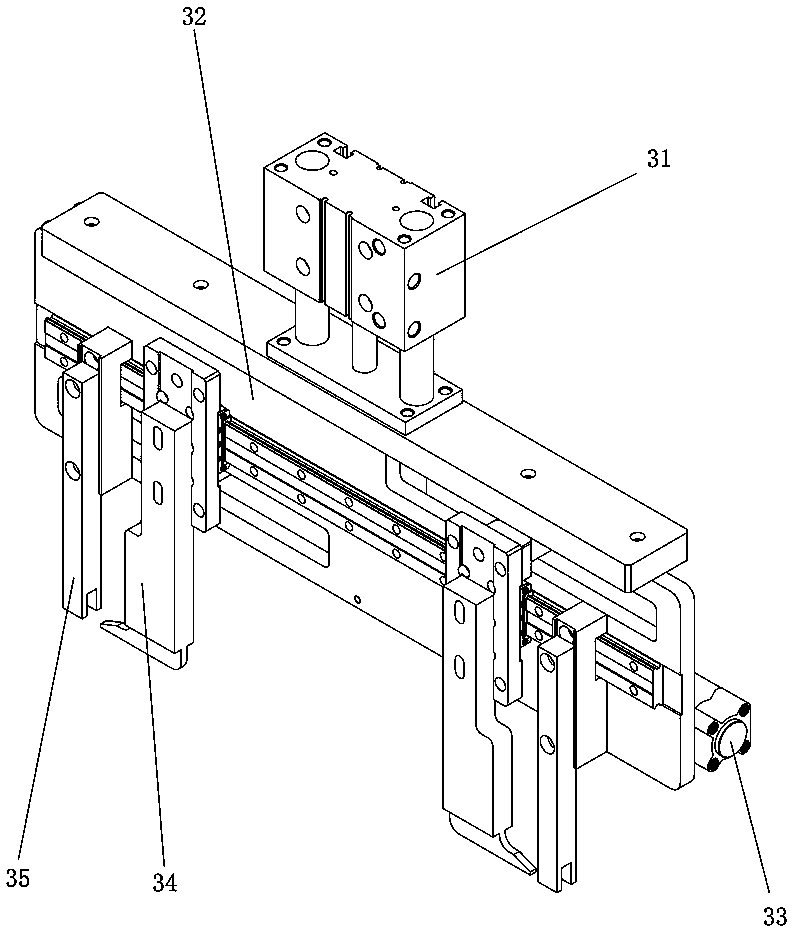

[0032] Figure 1 to Figure 6 It shows an embodiment of the automatic packing box tie removal device of the present invention, the packing box tie automatic removal device includes a box conveying member 1, a cutter assembly 2 and a tie removing assembly 3, along the box conveying member 1 is provided with a cutting station and a removal station successively in the conveying direction. The cutter assembly 2 is arranged at the cutting station and can remove the binding at the bottom of the packaging box 8 when the box conveying part 1 is transported to the removal station. The belt 9 is cut off, and the cable tie removal assembly 3 is arranged at the removal station and can remove the cut cable tie 9. The box conveying member 1 is used to drive the packing box 8 to be transported downstream, and the packing box 8 is transported downstre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com