Packaging film cutting device

A film device and packaging film technology, applied in packaging and other directions, can solve the problems of increasing production costs, limiting the packaging speed and efficiency of packaging equipment, etc., and achieve the effect of convenient spacing adjustment and continuous cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

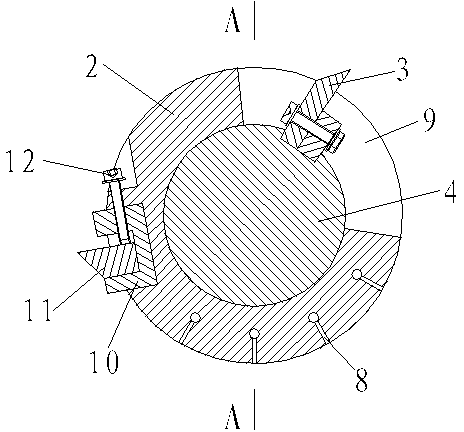

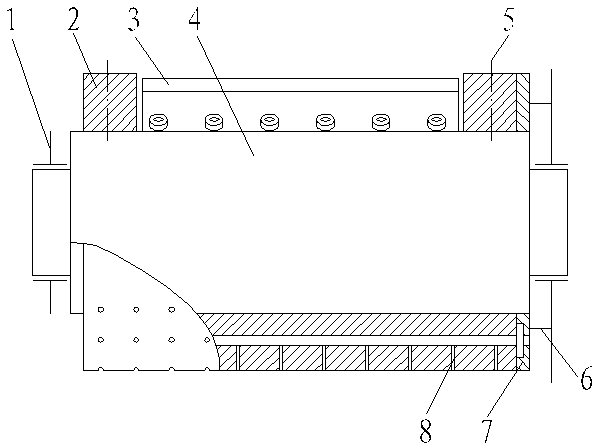

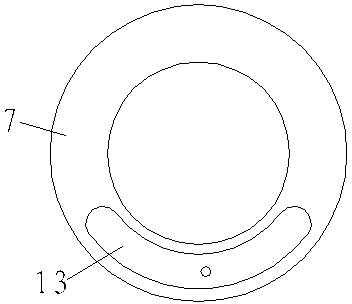

[0016] Such as figure 1 , 2 , 3, in the inner hole of the tubular outer roller body 2, the inner roller body 4 is matched, the inner and outer roller bodies can rotate relatively, and the outer roller body is provided with a long slot hole 9, and the dotted line knife 3 passes through the fixed The elongated fixing plate on the inner roller body is fixedly installed on the inner roller body, and stretches out the outer roller body through the slotted hole, and the cutting knife 11 is fixedly installed on the outer roller body by the U-shaped strip fixed on the outer roller body. When it is necessary to adjust the distance between the cutting knife and the dotted line knife, loosen the fixing screw 5 used as a positioning device, rotate the inner roller body, and make the arc length between the cutting knife and the dotted line knife reach the required length, and then go up Tighten the screws to make the relative positioning of the outer roller body and the inner roller body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com