Roller type tobacco cutting device

A cutting device, a roller-type technology, applied in the direction of tobacco, tobacco processing, application, etc., can solve the problems of uneven incision, complex equipment structure, and inability to ensure the consistency of the thickness of the cut tobacco.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

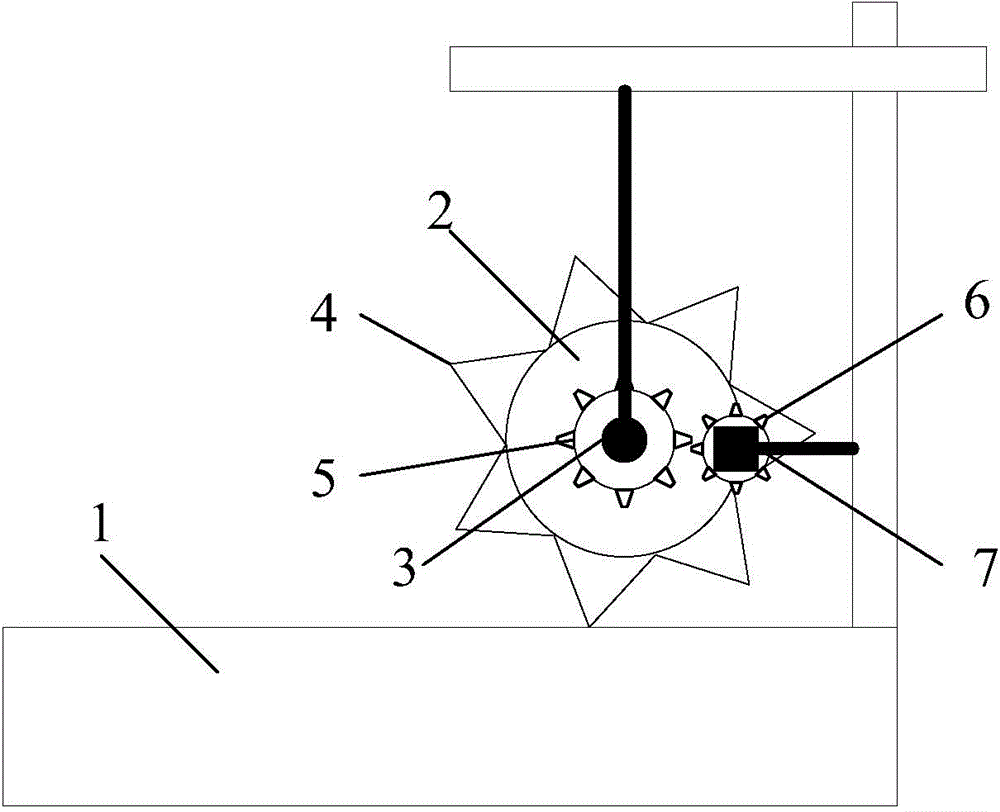

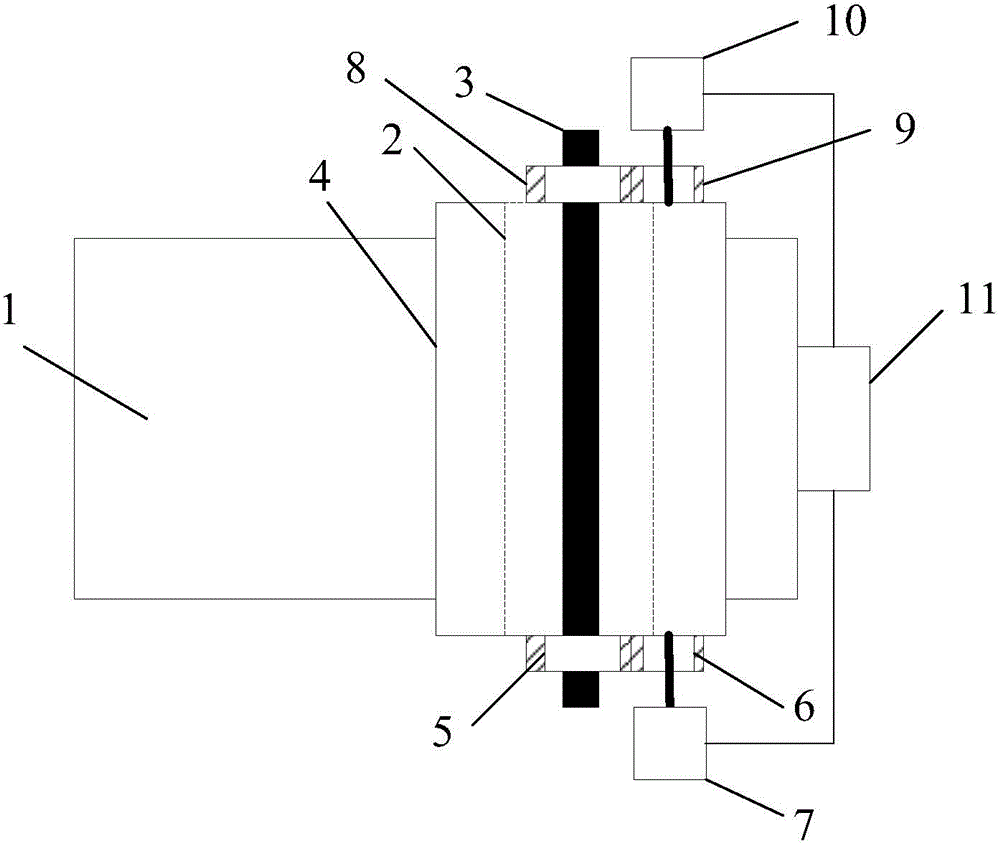

[0027] Embodiments of the present invention propose a roller-type tobacco cutting device, such as figure 1 and figure 2 As shown, it includes: an operating platform 1, which is used to place cut tobacco leaves; a roller 2, which is installed on the frame through a rotating shaft 3, is located at one end of the operating platform 1, and can rotate around the rotating shaft 3; the outer surface of the roller 2 is provided with A plurality of evenly distributed blades 4 parallel to the axis, the distance between two adjacent blades determines the width of the shredded tobacco; the first gear 5 is sleeved on the rotating shaft 3 and is fixedly connected to one end of the roller 2; the second gear 6 is connected to the first The gear 5 meshes, and the diameter of the first gear 5 is 2 to 3 times of the diameter of the second gear 6; the first motor 7 is installed on the frame, and the output shaft is equipped with the second gear 6; the rotation of the first motor 7 drives the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com