Turbocharger pressure shell assembly and gas compressor

A turbocharger and component technology, applied in the direction of machines/engines, pump components, mechanical equipment, etc., can solve problems such as lifting, achieve the effects of reducing noise, reducing interference, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

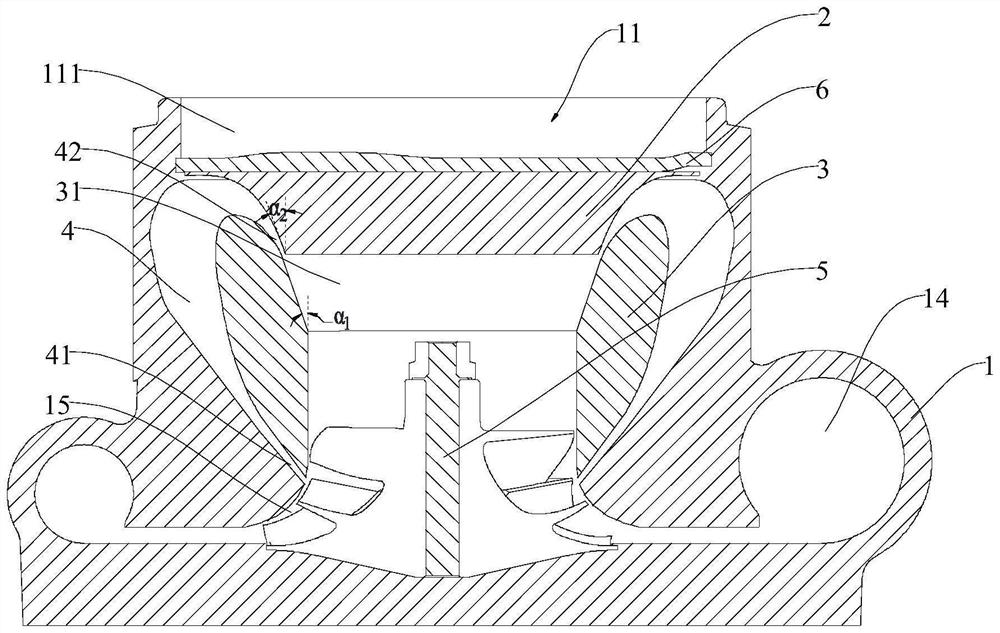

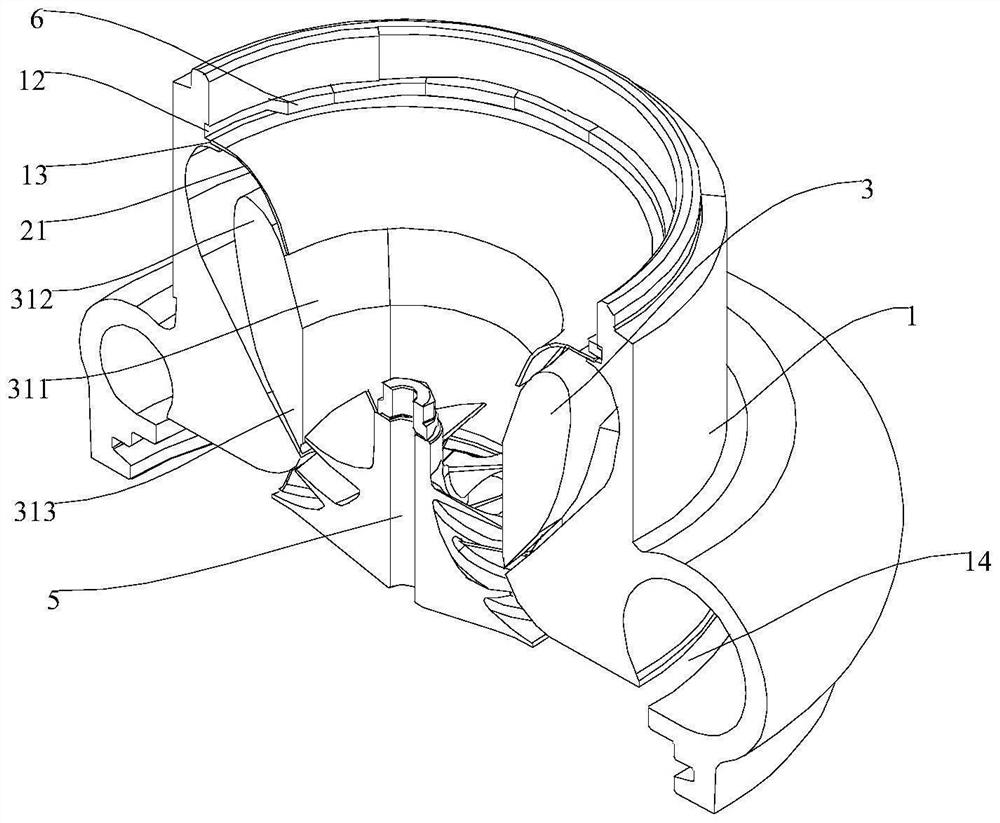

[0023] refer to Figure 1 to Figure 2 As shown, a turbocharger casing assembly of the present invention includes:

The pressure casing 1, the pressure casing 1 includes an air intake passage 11, and the air intake passage 11 includes an air inlet port 111;

A muffler cover 2, the muffler cover 2 is installed at the position of the air inlet 111 of the pressure shell 1;

the connecting part 3, the connecting part 3 is arranged in the intake passage 11;

The casing groove flow channel 4 is formed between the connecting part 3 and the inner wall of the pressure shell 1 and between the connecting part 3 and the muffler cover 2 , the casing groove flow channel 4 It includes a casing slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com