Axial flow-centrifugation integral bladed disc type combined compression system

An integral blisk and combined compression technology, applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve the problems of rotor torque transmission and operation reliability reduction, increase of rotor system parts, engine design difficulties, etc. Vibration margin, improve reliability, widen the effect of operating envelope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

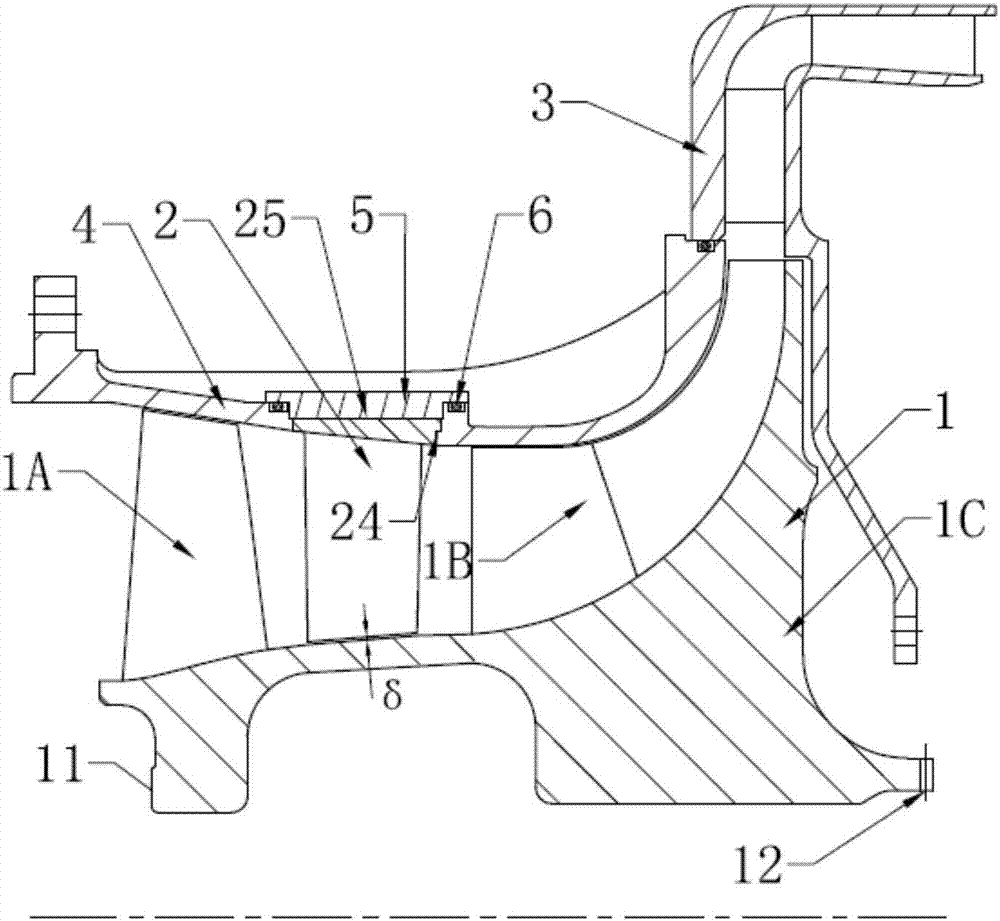

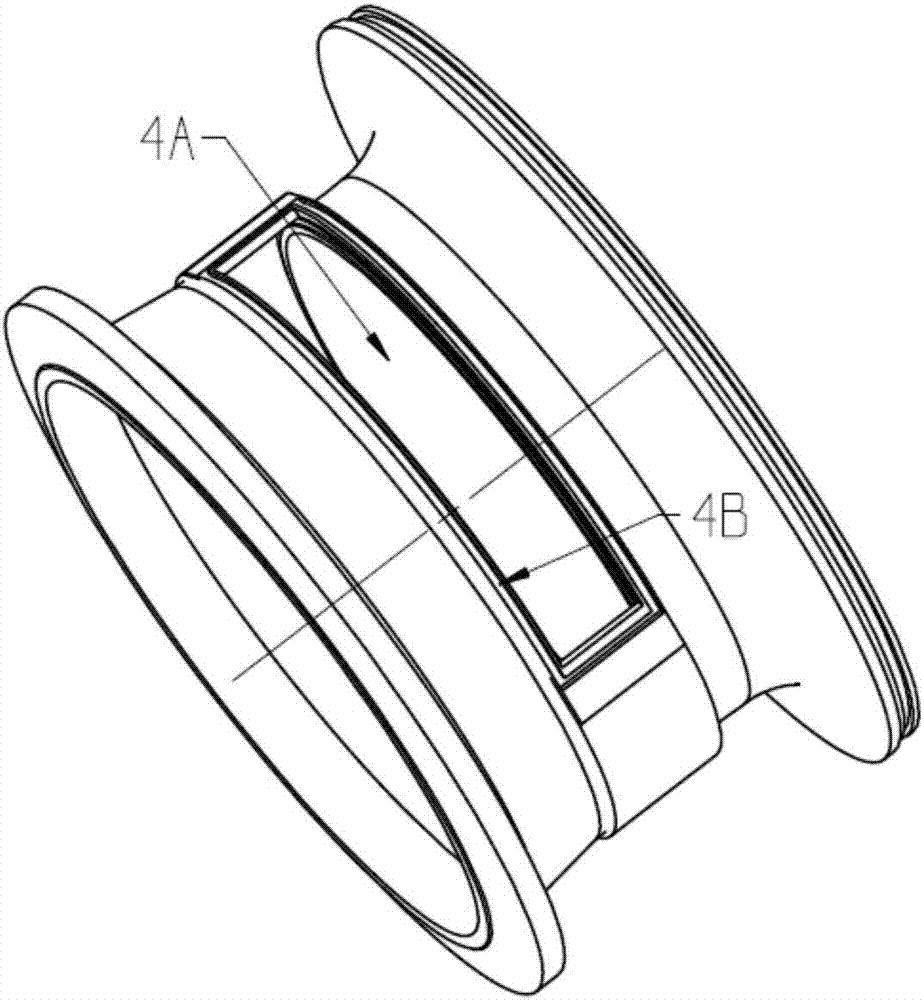

[0020] Such as figure 1 , 2 As shown, the axial flow-centrifugal integrated blisk type combined compression system of the present invention includes a first-stage axial flow compressor, a first-stage centrifugal compressor and a stator casing. The axial compressor includes an axial rotor and an axial stator 2 , and the centrifugal compressor includes a centrifugal impeller and a radial-axial diffuser 3 . Among them, the axial flow rotor is arranged upstream of the axial flow stator 2, the centrifugal impeller is arranged downstream of the axial flow stator 2, the axial flow stator is located between the axial flow rotor and the centrifugal impeller, and the radial-axial diffuser 3 is arranged in the centrifugal downstream of the impeller. The axial f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com