An air cooling system for an electric centrifugal air compressor

An air cooling system and air compressor technology, applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of increasing the length of the motor shaft, reducing the critical speed of the rotor system, and increasing the difficulty of installation, so as to improve the system Stability, improved surge margin, and small increase in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

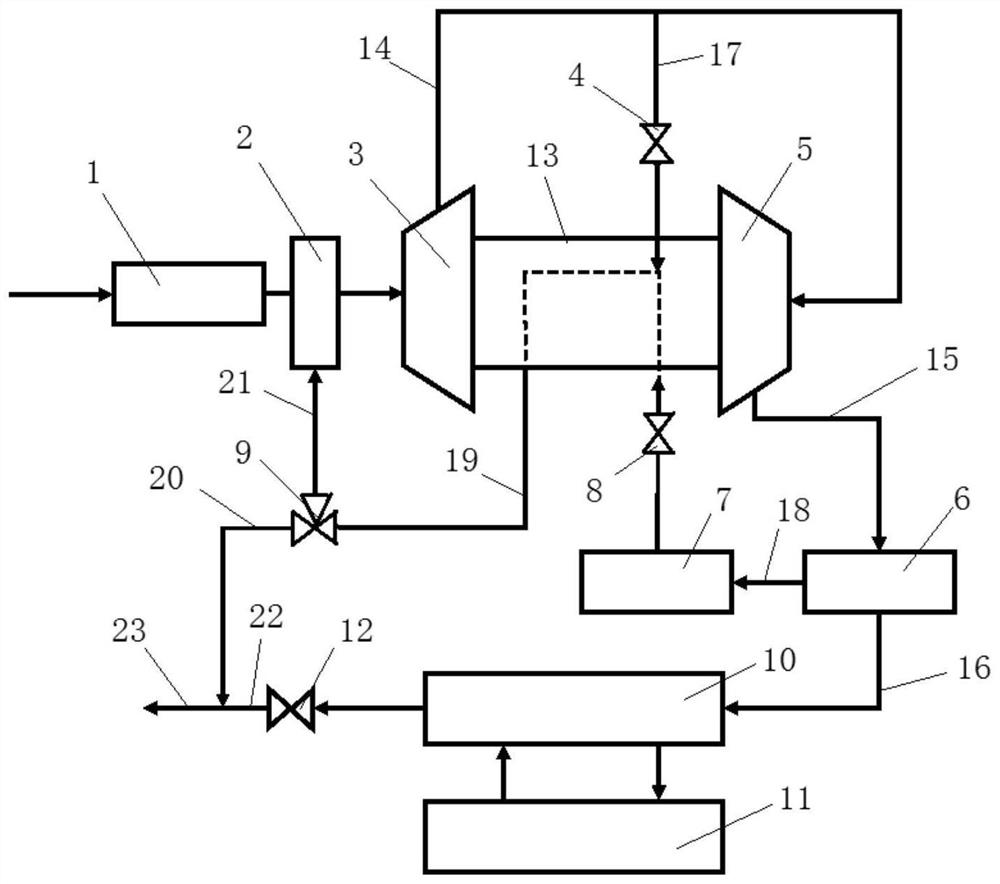

[0023] Such as figure 1 As shown, an air cooling system for an electric centrifugal air compressor includes a mixer 2, a first-stage compressor 3, a valve A4, a second-stage compressor 5, an intercooler 6, a second air filter 7, a valve B8, three Through valve 9, motor 13, compressed air pipe one 14, compressed air pipe two 15, compressed air pipe three 16, cooling air pipe one 17, cooling air pipe two 18, cooling exhaust pipe 19, exhaust pipe one 20, return air pipe 21 And exhaust manifold 23. Fresh air is filtered by the first air filter 1 and enters the mixer 2, and then enters the primary compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com