A casing processing structure and a compressor for improving the surge margin of a single-stage centrifugal compressor

A centrifugal compressor and casing treatment technology, applied in the field of compressors, can solve problems such as not being able to adapt to the increase in air intake volume of compressors, and achieve the effects of simple structure, easy maintenance, and improved surge margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

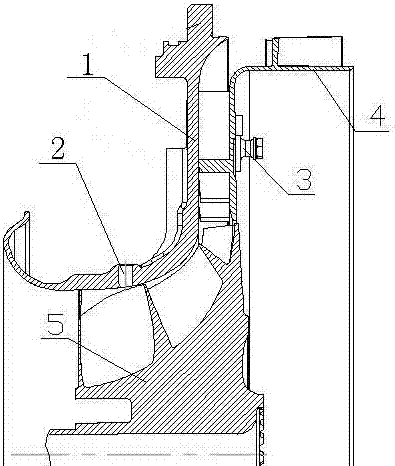

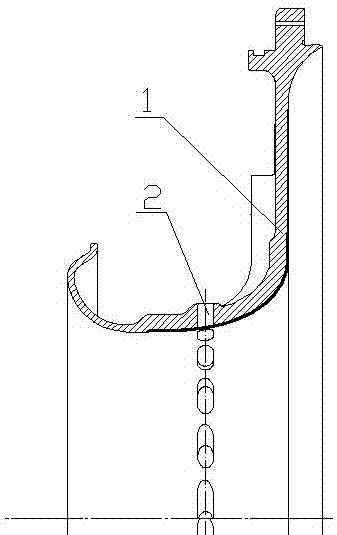

[0024] Such as figure 1 As shown, for a single-stage centrifugal compressor, this embodiment provides a casing processing structure that improves its surge margin. The single-stage centrifugal compressor includes an air inlet, an impeller 5, a diffuser 4, an air outlet, and a casing, and the air-inducing casing 1 is connected with the diffuser 4 by bolts 3; figure 1 , cutting off a part of the casing along the centerline direction of the impeller to obtain figure 1 The schematic diagram of the structure is shown.

[0025] The impeller 5 is provided with many pairs of large blades and small blades, and the large blades and small blades all include blade tips, and the blade tip includes a blade tip leading edge and a blade tip throat, and the outermost edge of the blade is close to the casing inlet. The position is called the leading edge of the blade tip, and the part with the smallest cross-sectional area of the blade is called the blade tip throat; the air inlet, the impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com