Method, system and terminal for optimizing gas compressor casing treatment to improve stability margin

A casing processing and stability margin technology, which is applied in the field of compressors, can solve the problems of severe fluctuations in the outlet pressure of the compressor, inability to adapt to the increase in the intake air volume of the compressor, and increased surge margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

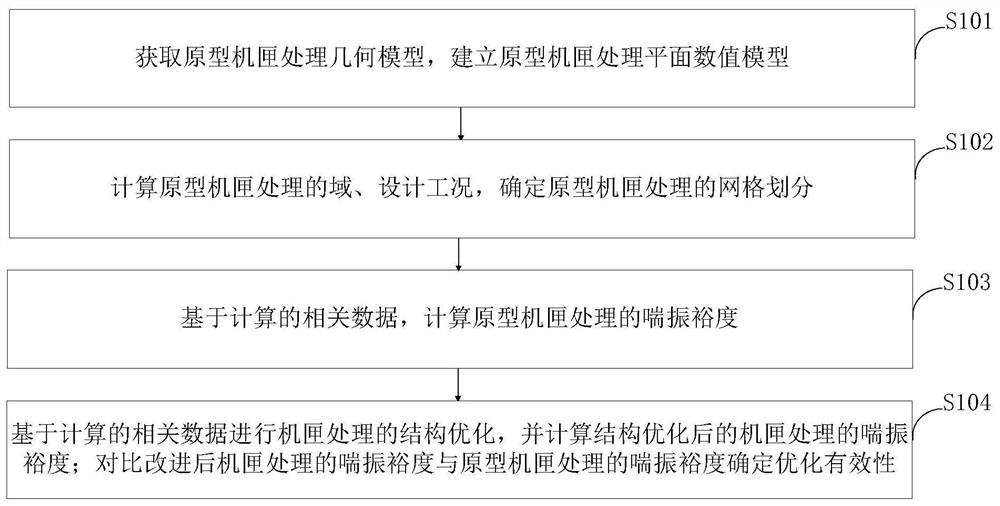

[0104] 1. Prototype casing processing numerical calculation

[0105] (1) Prototype casing processing geometry model

[0106] The prototype case processing model is a structure with an axial chute and a return chamber.

[0107] (2) Establish a plane numerical model

[0108] Prototype case handling structure with axial chute and return chamber.

[0109] 2. Numerical calculation

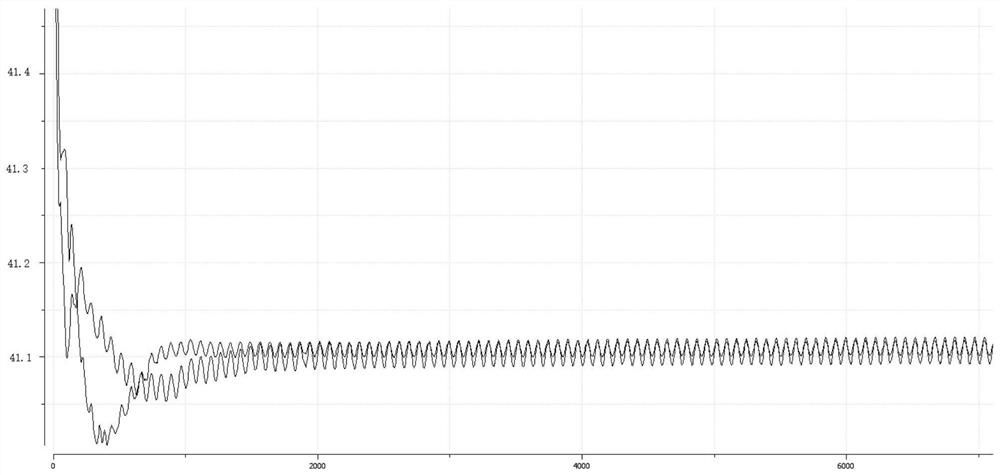

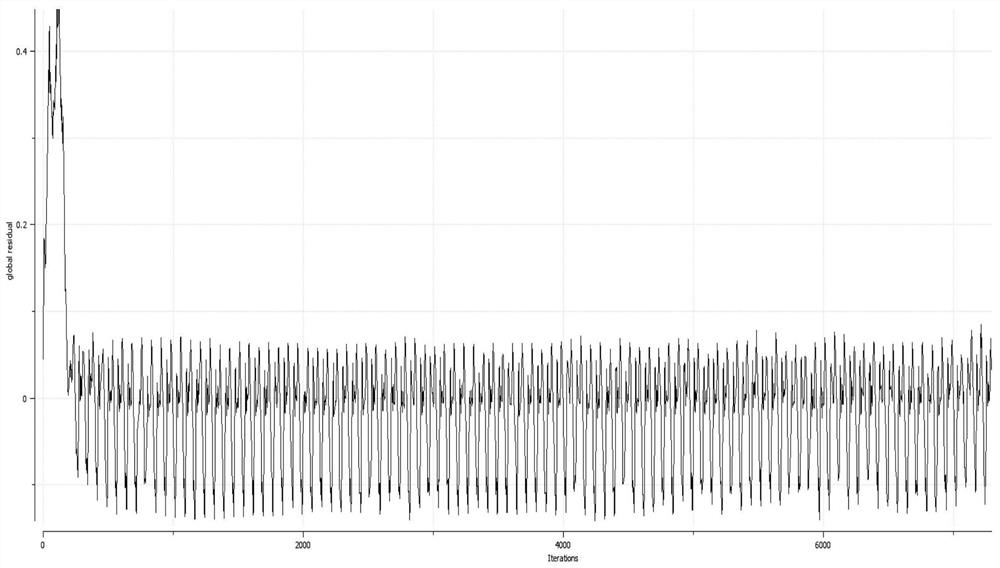

[0110] 2.1 Computational domain

[0111] The CFD method is used to simulate the turbine flow field. In order to reduce the amount of calculation, the periodic boundary processing method is adopted. The calculation domain only includes one flow channel. In addition, in order to ensure the calculation convergence, the outlet position is moved downstream along the Z axis (flow direction of the working medium). Extend 1 times the chord length of the rotor blade.

[0112] 2.2 Grid division

[0113]The calculation grid adopts visual IGG / AutoGrid5 to divide the single-channel grid, and the entire calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com