Super/transonic compressor with front sharp and blunt trailing edge bodies and design method thereof

A technology of compressor and trailing edge body, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of increasing the processing difficulty and manufacturing cost of compressor blades, affecting the strength and vibration characteristics of the compressor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

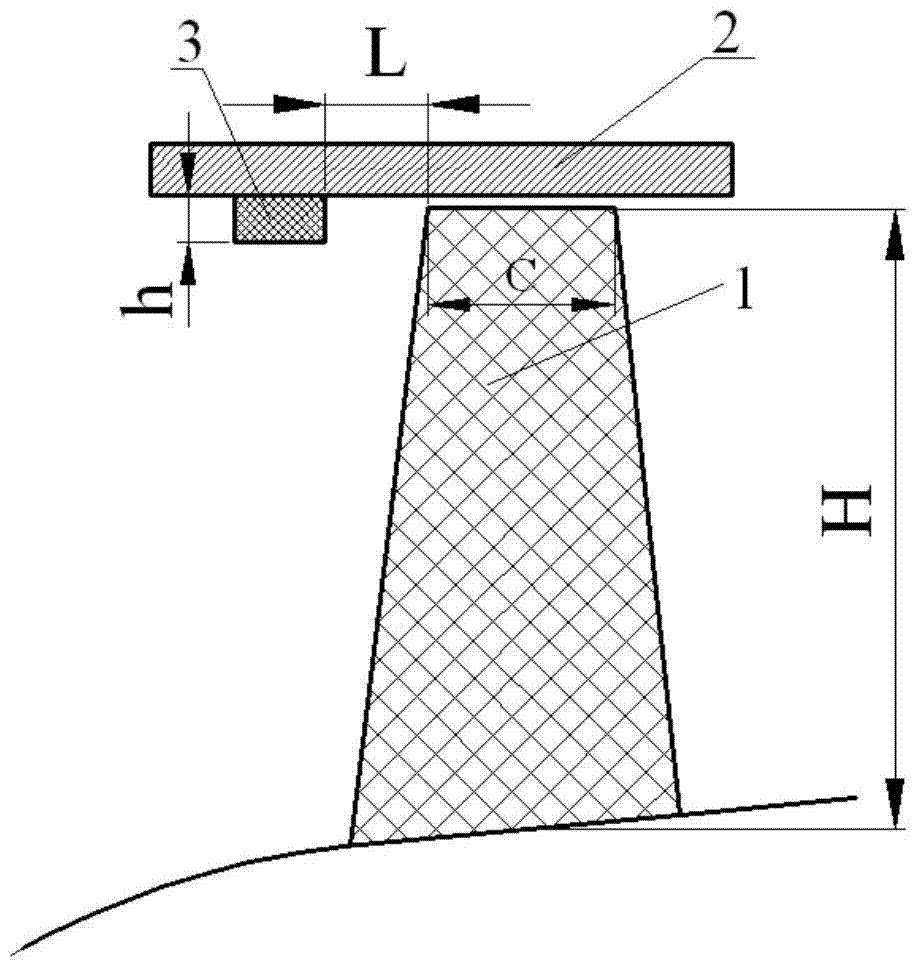

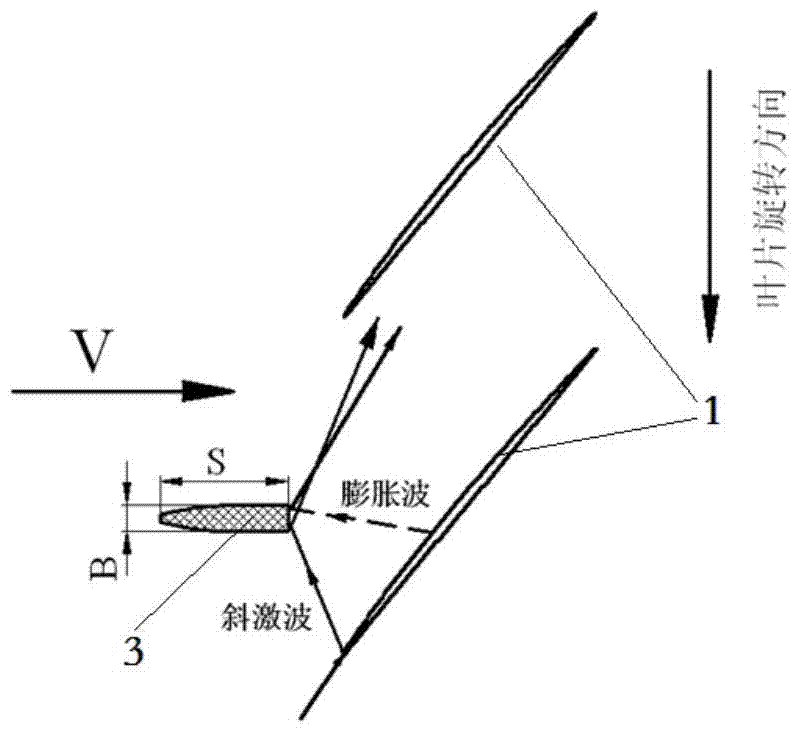

[0017] like figure 1 As shown, the compressor used in this embodiment for a high-performance aero-engine consists of a compressor rotor 1, a compressor outer casing 2 and a front sharp blunt trailing edge body 3. In order to effectively control the shock wave near the tip of the compressor blade 4 on the compressor rotor 1 and improve the stable working margin of the super / transonic compressor, a number of The sharp blunt trailing edge body 1 is 1 / 8~1 / 5 of the number of compressor blades (the minimum number of sharp blunt trailing edge bodies is not less than 3), and the sharp blunt trailing edge body 1 is located 1 / 4 away from the leading edge of the compressor blade tip ~1 / 3 of the axial chord length of the blade tip of the compressor, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com