Preventing electrical breakdown

An electromechanical and housing technology, applied in the direction of electromechanical devices, electrical components, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

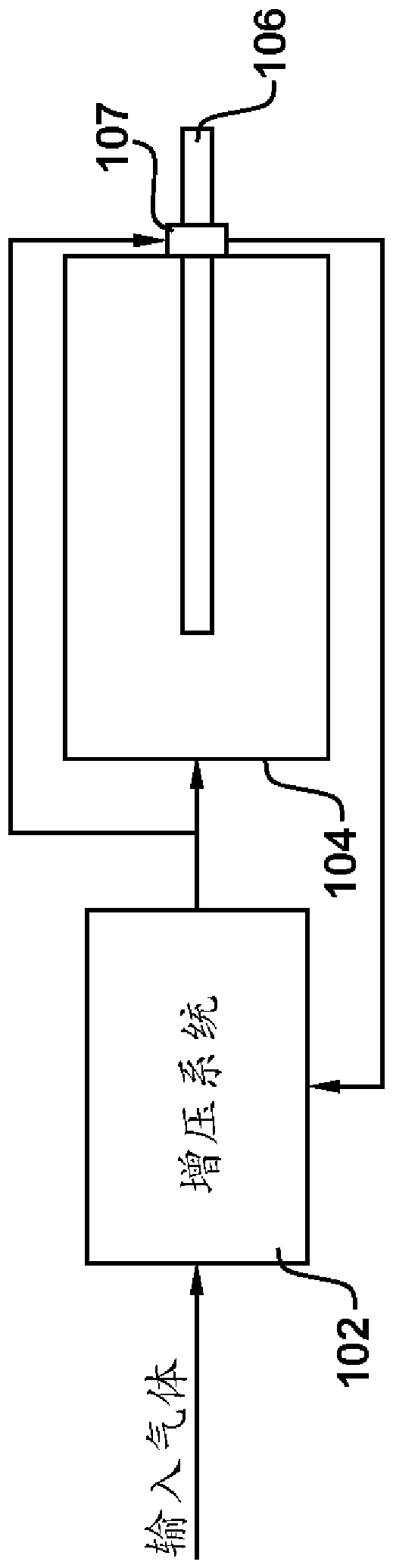

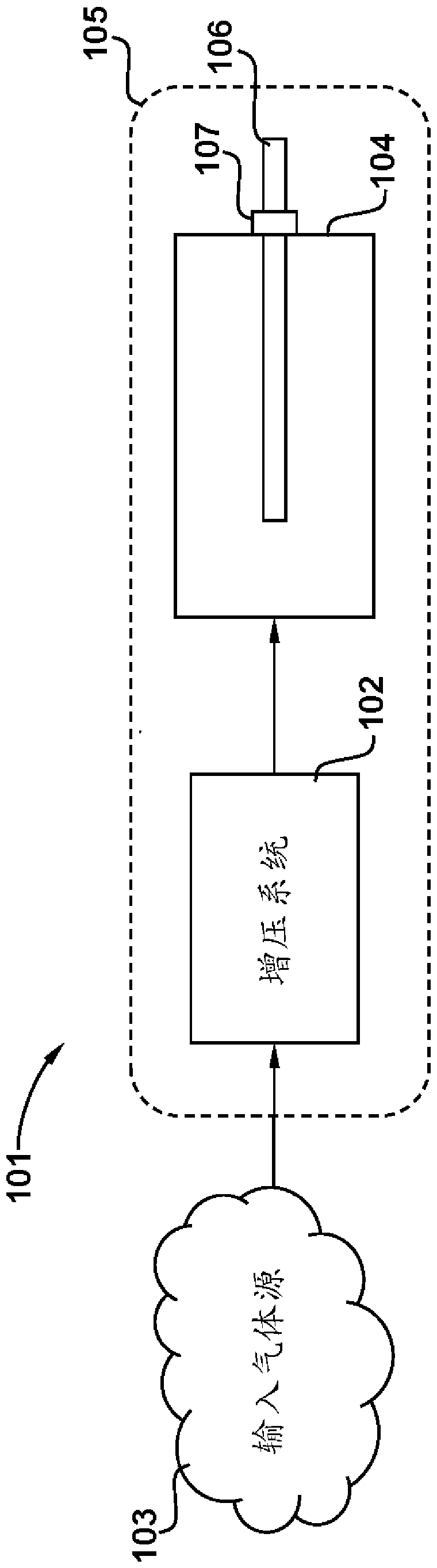

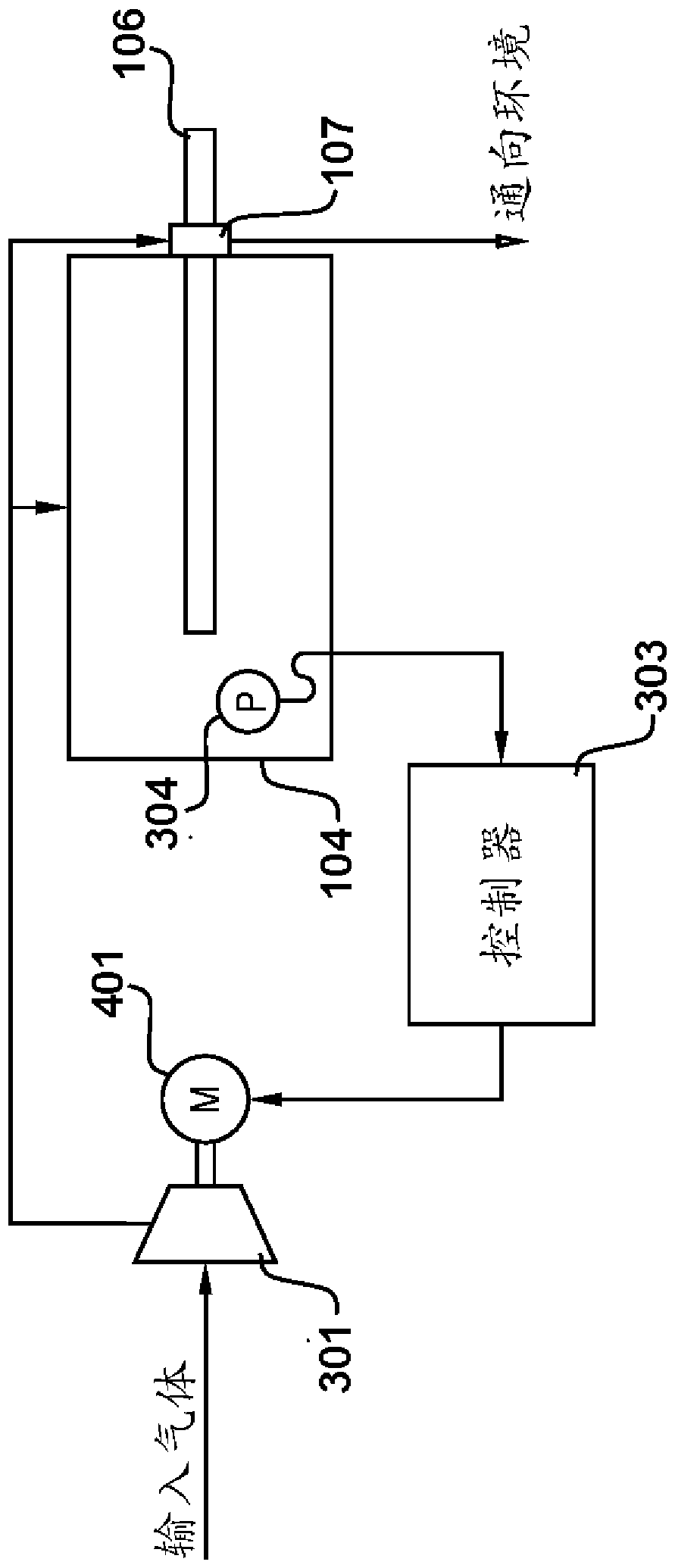

[0020] exist figure 1 A block diagram illustrating an embodiment is shown in , where the motor is shown generally at 101 . The electric machine 101 includes a booster system 102 that receives a supply of input gas from an input gas source 103 . The input gas source 103 may be atmospheric air or, as previously mentioned, a source of pre-pressurized gas, such as an aircraft's bleed air system or cabin exhaust.

[0021] The pressurization system 102 operates to pressurize the housing 104 of the electric machine 101 above the external pressure of the environment 105 in which the electric machine 101 is located.

[0022] The housing 104 houses electromechanical components (not shown) that effectuate the conversion of electrical power into work on the shaft 106 or vice versa depending on the assigned role of the electric machine 101 (eg whether operating as a motor or a generator). It will be appreciated that the exact configuration of the electromechanical components within the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com