Self-circulation type treatment casing structure of gas compressor of ship gas turbine

A technology for handling casings and gas turbines. It is used in machines/engines, liquid fuel engines, mechanical equipment, etc., and can solve problems such as low operating conditions stability, and achieve the effects of increasing surge margin, accelerating inlet speed, and delaying stall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

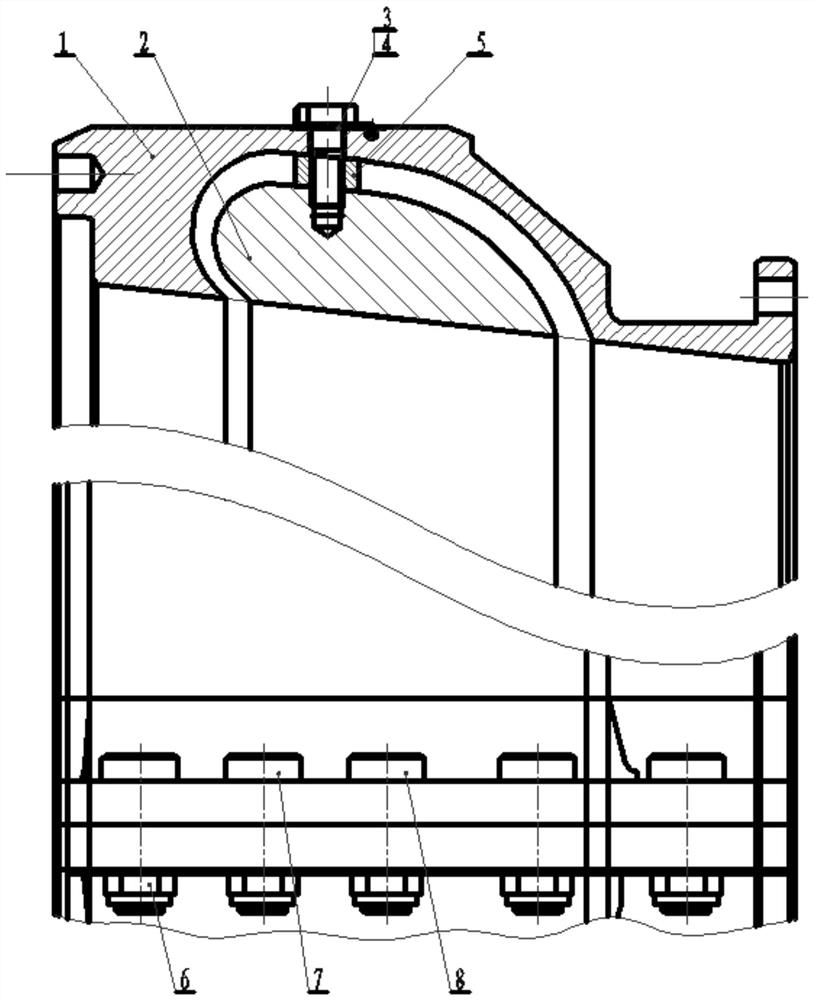

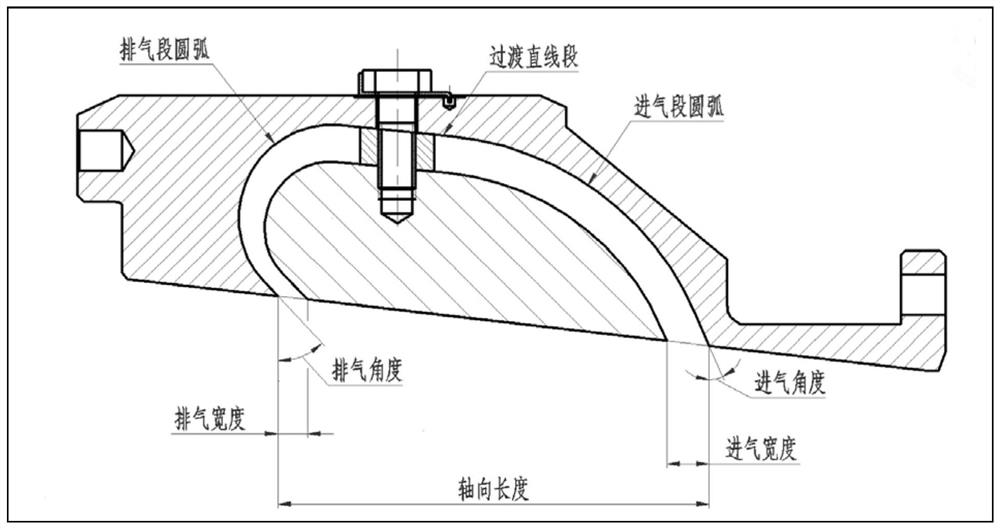

[0014] refer to figure 1 , a marine gas turbine compressor self-circulating processing casing structure, including an outer ring 1, an inner ring 2, screws 3, locking washers 4, bosses 5, self-locking nuts 6, tight fit bolts 7 and bolts 8. The outer ring 1 and the inner ring 2 are connected by screws 3 and locking washers 4, wherein in order to increase the connection strength between the inner and outer rings, a boss 5 is welded on the outer side of the inner ring. The upper and lower half casings are fixed by self-locking nuts 6, tight fit bolts 7 and bolts 8; the bolts 8 are positioned and the tight fit bolts 7 are tightly fitted. The gap between the outer and inner rings forms the bleed flow path for the disposal case. In order to increase the connection strength between the inner and outer rings, bosses are welded outside the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com