Hydrophilic processing method for zinc nickle alkaline accumulator diaphragm

A technology for hydrophilic treatment and storage batteries, which is applied in battery pack parts, circuits, electrical components, etc., can solve the problems of inability to apply zinc-nickel storage batteries, and achieve good hydrophilic liquid absorption performance, improved cycle life, and good air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

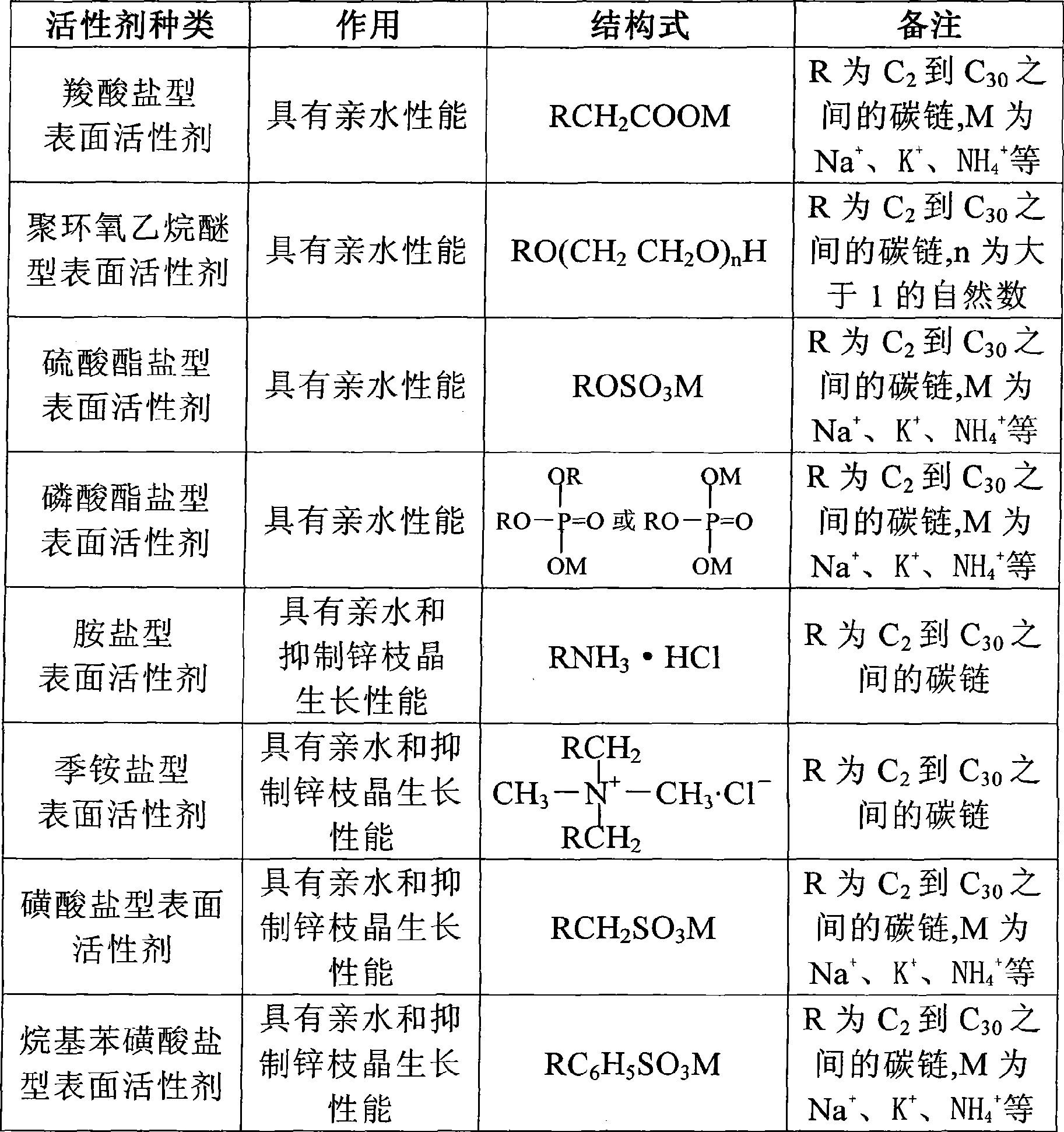

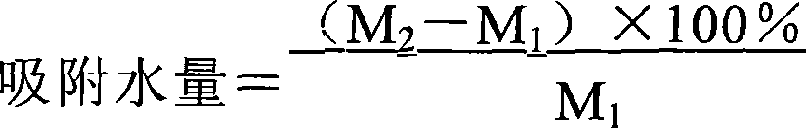

Method used

Image

Examples

Embodiment 1

[0048] This embodiment illustrates a method for treating non-hydrophilic diaphragms with hydrophilicity:

[0049] a. Preparation of hydrophilic treatment solution

[0050] By weight percentage as follows:

[0051] Hydrophilic Surfactant: C 8 h 17 CH 2 COONa 0.1%

[0052] Oxidant: hydrogen peroxide 1%

[0053] Ketones: Acetone 3%

[0054] Alcohols: Isopropanol 3%

[0055] Deionized water: balance

[0056] b. The non-hydrophilic diaphragm is completely immersed in the hydrophilic treatment solution for 5 minutes;

[0057] c. Clean the treated diaphragm with deionized water until the pH value reaches 7;

[0058] d. Prepare coating solution

[0059] By weight percentage as follows:

[0060] Additives for inhibiting zinc dendrite growth: C 8h 17 CH 2 NH 3 ·HCl 6%

[0061] Deionized water: balance

[0062] e. The diaphragm is completely immersed in the coating layer solution for 2 minutes;

[0063] f. Dry at 65°C or dry naturally.

[0064] Note: This proportion of...

Embodiment 2

[0068] This embodiment illustrates a method for treating non-hydrophilic diaphragms with hydrophilicity:

[0069] a. Preparation of hydrophilic treatment solution

[0070] By weight percentage as follows:

[0071] Hydrophilic Surfactant: C 9 h 19 CH 2 OSO 3 Na 6%

[0072] Oxidizer: sodium hypochlorite 3%

[0073] Ketones: Acetone 2%

[0074] Alcohols: Isopropanol 2%

[0075] Alkalis: Potassium Hydroxide 0.5%

[0076] Deionized water: balance

[0077] b. The non-hydrophilic diaphragm is completely immersed in the hydrophilic treatment solution for 20 minutes;

[0078] c. Clean the treated diaphragm with deionized water until the pH value reaches 7;

[0079] d. Prepare coating solution

[0080] By weight percentage as follows:

[0081] Additives for inhibiting zinc dendrite growth: C 8 h 17 CH 2 NH3·HCl 6%

[0082] Deionized water: balance

[0083] e. The diaphragm is completely immersed in the coating layer solution for 5 minutes;

[0084] f. Dry at 75°C or d...

Embodiment 3

[0087] This embodiment illustrates a method for treating non-hydrophilic diaphragms with hydrophilicity:

[0088] a. Preparation of hydrophilic treatment solution

[0089] By weight percentage as follows:

[0090] Hydrophilic Surfactant: C 12 h 25 C 6 h 5 SO 3 K 16%

[0091] Oxidant: hydrogen peroxide 1%

[0092] Ketones: Acetone 2%

[0093] Alcohols: Ethanol 3%

[0094] Deionized water: balance

[0095] b. The non-hydrophilic diaphragm is completely immersed in the hydrophilic treatment solution for 30 minutes;

[0096] c. Clean the treated diaphragm with deionized water until the pH value reaches 7;

[0097] d. Prepare coating solution

[0098] By weight percentage as follows:

[0099] Additive for inhibiting zinc dendrite growth: tetrabutylammonium bromide 0.1%

[0100] Deionized water: balance

[0101] e. The diaphragm is completely immersed in the coating layer solution for 1min;

[0102] f. Dry at 85°C or dry naturally.

[0103] Note: This proportion of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com