Preparing method of super-hydrophobic polyvinylidene fluoride membrane and its application in gas-liquid membrane contactors

A polyvinylidene fluoride film and a technology of polyvinylidene fluoride are applied in the field of preparation of super-hydrophobic polyvinylidene fluoride film, which can solve the problems of complex production process, insufficient hydrophobicity of PVDF film, unsuitable for large-area preparation, etc. Good performance, low cost, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

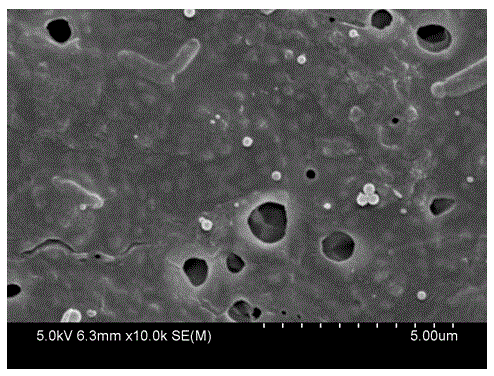

Image

Examples

Embodiment 1

[0039] Mix the dried polyvinylidene fluoride powder and N,N-dimethylacetamide at a weight ratio of 20:80, and stir slowly for 5 hours on a magnetic stirrer with heating, so that the temperature of the membrane liquid is controlled at 50°C , to obtain a uniform and clear casting solution; then put the casting solution in a 50°C oven, let it stand for degassing for 20 hours, make it fully mature, and set it aside.

[0040] At room temperature, scrape the casting solution on the glass plate evenly and quickly, then use the phase inversion method to form a film in the coagulation bath of purified water, soak in the coagulation bath of purified water for 12 hours, wash and dry in vacuum Dried in a container.

[0041] Disperse the Zonyl® 8740 surfactant evenly in distilled water to obtain a homogeneous and transparent aqueous solution. The concentration of the Zonyl® 8740 aqueous solution is 10%, and it is ready for use.

[0042] Finally, soak the polyvinylidene fluoride film in Zo...

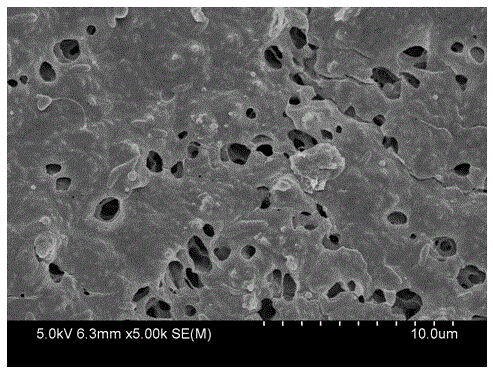

Embodiment 2

[0044] Mix the dried polyvinylidene fluoride powder and N,N-dimethylacetamide at a weight ratio of 15:85, and stir slowly on a heated magnetic stirrer for 8 hours to control the temperature of the membrane liquid at 70°C , to obtain a uniform and clear casting solution; then put the casting solution in an oven at 70°C, and let it stand for degassing for 24 hours, so that it can be fully matured and ready for use.

[0045] At room temperature, scrape the casting solution evenly and quickly on the glass plate, and then use the phase inversion method to form a film in the coagulation bath of n-propanol. After soaking in the coagulation bath of n-propanol for 20 hours, wash , dried in a vacuum desiccator.

[0046] Disperse the Zonyl® 8740 surfactant evenly in distilled water to obtain a homogeneous and transparent aqueous solution. The concentration of the Zonyl® 8740 aqueous solution is 15%, and it is ready for use.

[0047] Finally, soak the polyvinylidene fluoride film in Zony...

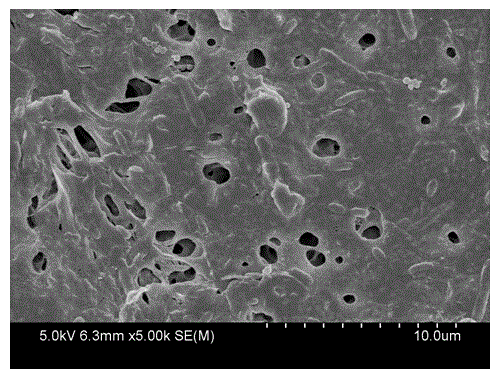

Embodiment 3

[0049]Mix the dried polyvinylidene fluoride powder and N,N-dimethylacetamide at a weight ratio of 10:90, and stir slowly for 7 hours on a magnetic stirrer with heating, so that the temperature of the membrane liquid is controlled at 60°C , to obtain a uniform and clear casting solution; then put the casting solution in an oven at 60°C, and let it stand for degassing for 24 hours, so that it can be fully matured and ready for use.

[0050] At room temperature, scrape the casting solution evenly and quickly on the glass plate, and then use the phase inversion method to form a film in the coagulation bath of ethanol, soak in the coagulation bath of ethanol for 24 hours, wash and dry in vacuum appliance dry.

[0051] Disperse the Zonyl® 8740 surfactant evenly in distilled water to obtain a homogeneous and transparent aqueous solution. The concentration of the Zonyl® 8740 aqueous solution is 5%, and set aside.

[0052] Finally, soak the polyvinylidene fluoride film in a Zonyl® 874...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com