Pure waterborne epoxy floor paint as well as preparation method and use method thereof

An epoxy floor paint, water-based epoxy technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of long storage time, poor control of dosage and temperature, and achieve less harm to human body, no harm to the human body. The effect of easy bubble peeling, good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

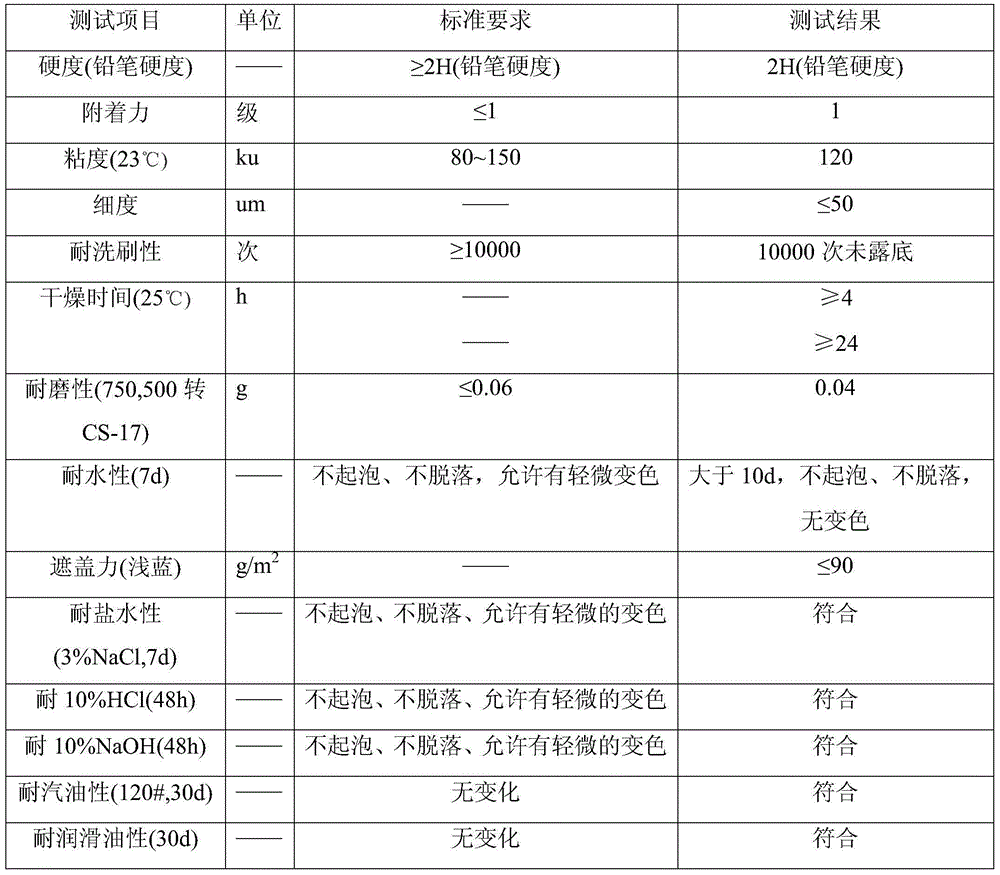

Embodiment 1

[0021] The first step, the production of slurry. At room temperature, 59.4kg of pure water is placed in the batching container, and the stirrer is turned on at 400 rpm. At this speed, 1.2kg of the grinding and dispersing agent produced by the American Gas Chemical Company, 0.4kg of the CT-136, and 0.4kg of the American Low-foaming wetting agent of model DC01 produced by Gas Chemical Company, 1kg of modified polysiloxane defoamer of model 5700 produced by American Gas Chemical Company, 2kg of micro wax powder of model FS511 produced by American Mitsuba Company , 30kg of R-902 type rutile titanium dioxide produced by American DuPont Company, 6kg of 300 mesh high-purity silicate glass powder and 20kg of quartz powder. After adding the above raw materials, adjust the speed of the mixer to 1000 rpm, and continue stirring for about 30 minutes to form a slurry.

[0022] The second step is to mix the slurry with the water-based epoxy curing agent. Slowly add 80kg of water-soluble al...

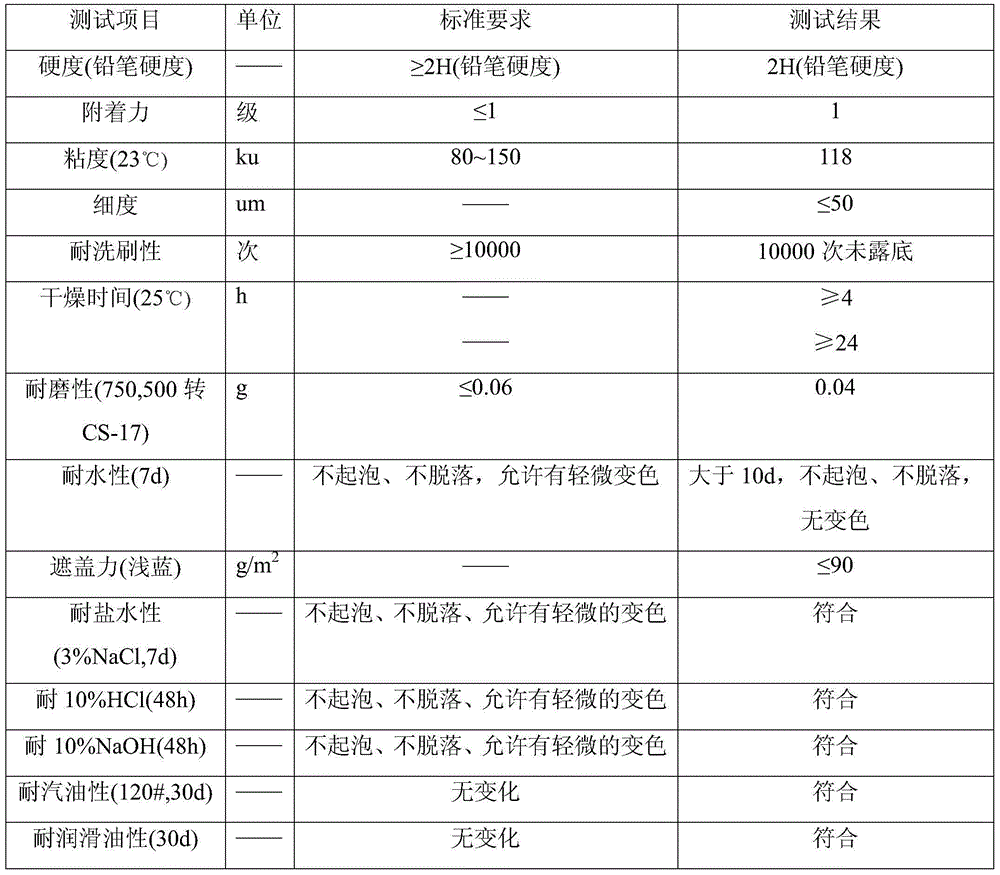

Embodiment 2

[0027] The first step, the production of slurry. At room temperature, put 29.7kg of pure water in the batching container, turn on the mixer at 600 rpm, at this speed, add 0.6kg of silicate dispersant, 0.2kg of sodium dodecylsulfonate wetting agent in sequence , 0.5kg of polyamide defoamer, 1kg of FS511 micro-wax powder produced by American Sanye Company, 15kg of R-902 model rutile titanium dioxide produced by American DuPont Company, 3kg of 300 mesh high-purity silicate glass powder and 10kg Quartz powder. After adding the above raw materials, adjust the speed of the mixer to 1200 rpm, and continue stirring for about 35 minutes to form a slurry.

[0028] The second step is to mix the slurry with the water-based epoxy curing agent. Slowly add 40kg of water-soluble aliphatic modified amine curing agent to the above-mentioned just-prepared slurry, adjust the speed of the mixer to 450 rpm, and continue stirring for 5 to 10 minutes to form the pure water-based ring of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com