Method for preparing OLED device

A device and process technology, applied in the field of light-emitting display, can solve problems such as poor film thickness uniformity, and achieve the effect of uniform film thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical scheme of a method for manufacturing an OLED device involved in the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0036] One embodiment of the present invention provides a method for preparing an OLED device, comprising the following steps:

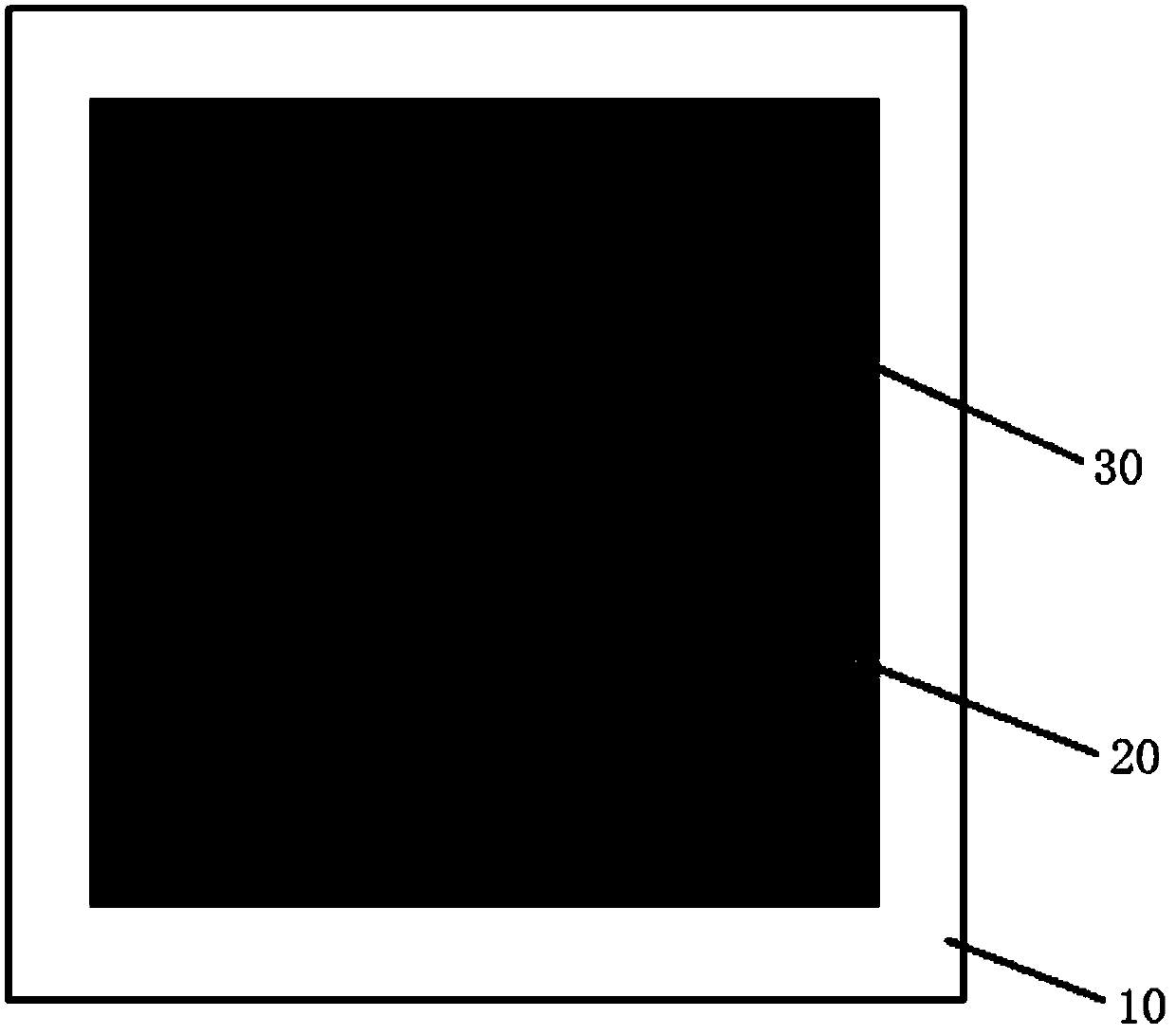

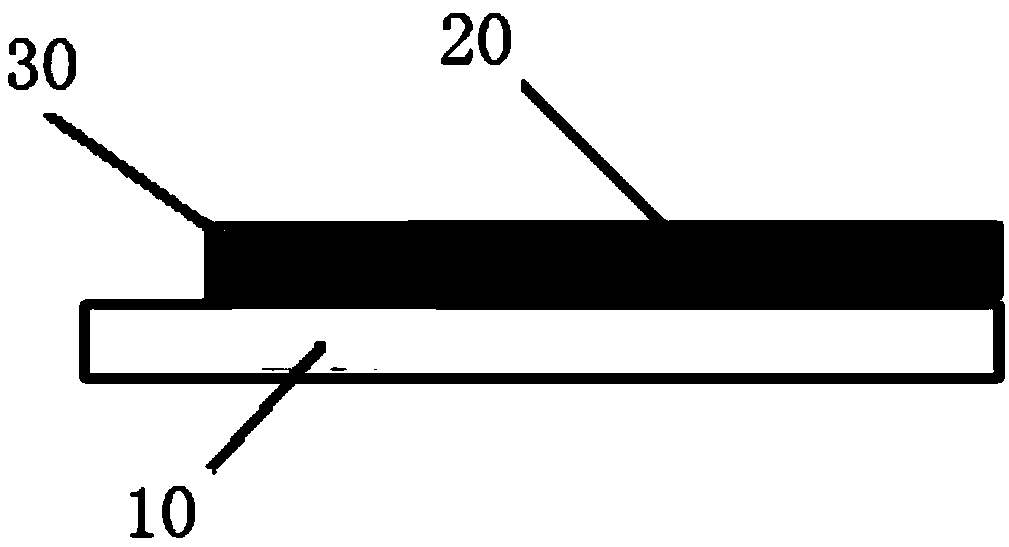

[0037] providing a substrate on which a display area is defined and a temporary coating area located outside the edge of the display area, wherein the temporary coating area is disposed adjacent to the edge of the display area and surrounds the display area;

[0038] The prepared volatile organic resin is coated on the temporary coating area by coating to form a dummy area, and the width of the temporary coating area on each side of the display area is between 2 mm and 100 mm. For example, 15mm, 20mm, 30mm, 50mm, 60mm, etc., the details can be determined according to the needs, and there is no limit;

[0039] Coating a blank solvent of print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com