Electrolysis method of continuous terminal

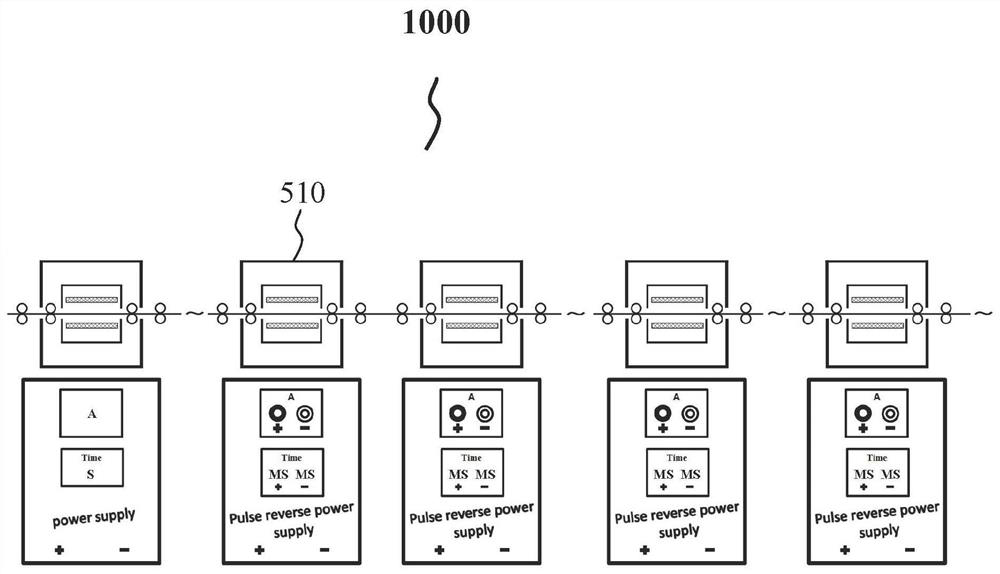

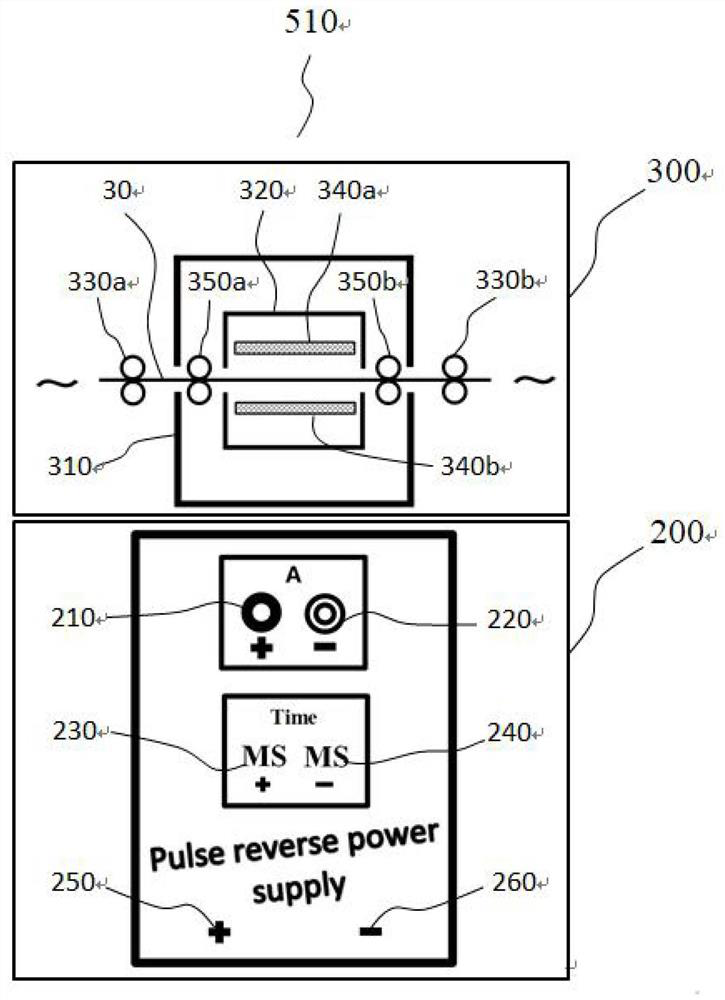

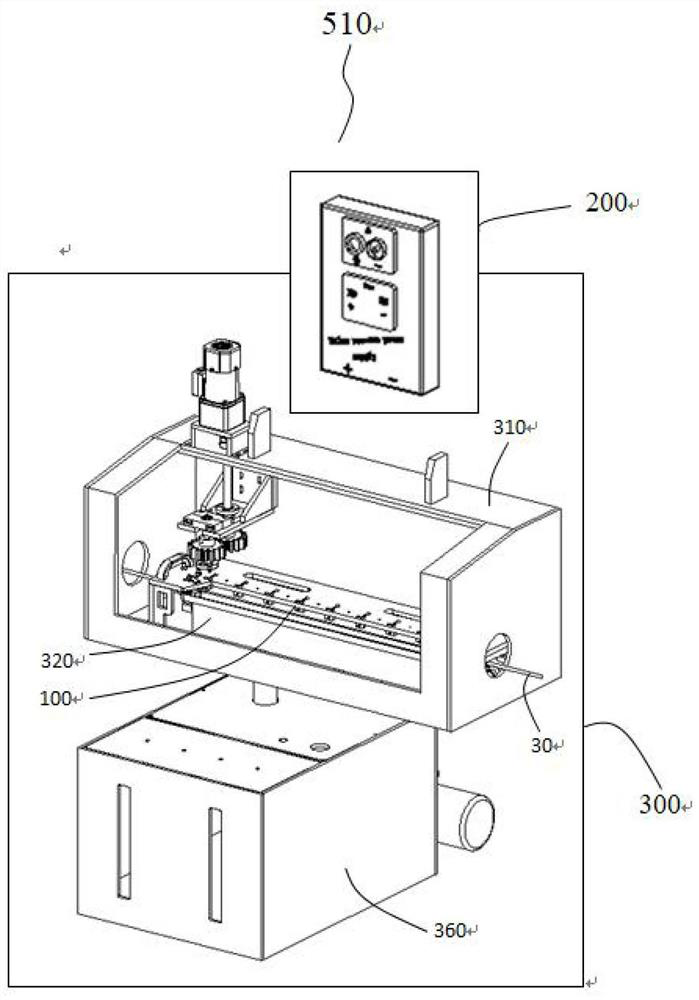

An electrolysis method and terminal technology, applied in the field of electrolysis surface treatment, can solve the problems of uneven distribution of precious metal film thickness, complex structure of local electrolysis equipment, high maintenance cost, etc., and achieve the effects of saving precious metal usage, simple structure and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125](1) Continuous terminal material (material 30): phosphor bronze material, terminal width 13mm, width 0.64mm, thickness 0.16mm; continuous terminal material is pre-plated with nickel film thickness Min 2.0μm, terminal product film thickness measurement point: distance from terminal 1.7mm at the tip, and 0.32mm in the middle of the terminal width ( Figure 13 , 14 ).

[0126] (2) Specifications of continuous terminal electrolytic products: Rh / Ru with a minimum Min 1.27μm is required on one side and one side; no rhodium and ruthenium can be attached to the other side; the thickness of the gold-plated film is 0.03-0.05μm, and the range is consistent with the Rh / Ru plating. Gold cannot be attached to the other side.

[0127] The specific manufacturing process of continuous terminal products is:

[0128] Using the usual roll-to-roll continuous terminal surface treatment production line, the continuous terminal material is introduced into the electrolytic degreasing tank thr...

Embodiment 2

[0149] (1) Continuous terminal material: phosphor bronze material, terminal width 15mm, width 0.64mm, thickness 0.16mm; continuous terminal material is pre-plated with nickel film thickness Min2.0μm, terminal product film thickness measurement point: 2mm from the terminal tip, and 0.32mm in the middle of the terminal width ( Figure 15 and Figure 16 ).

[0150] Table 2: Allocation quota of coating surface film thickness for manufacturing of 9 pulse reverse power supplies Unit: μm

[0151]

[0152]

[0153]

[0154] (2) Specifications of continuous terminal electrolytic products: palladium-nickel with minimum Min 1.52μm is required on one side and part of the side; palladium-nickel cannot be attached to the other side; the thickness of the plated gold film is 0.03-0.05μm, and the range is consistent with that of the plated Pd / Ni. Gold cannot be attached to one side.

[0155] The specific manufacturing process of continuous terminal products is:

[0156] Using the ...

Embodiment 3

[0169] (1) Continuous terminal material: phosphor bronze material, terminal width 13mm, width 0.64mm, thickness 0.16mm; continuous terminal material is pre-plated with nickel film thickness Min 2.0μm, terminal product film thickness measurement point: 1.7mm from the terminal tip, and terminal width middle 0.32mm ( Figure 13 and 14 ).

[0170] (2) Continuous terminal electrolytic product specifications: palladium-nickel with a minimum Min 0.38μm is required on one side and one side; the other side cannot be attached to palladium-nickel; the thickness of the plated gold film is ≧0.76μm, and the range is consistent with that of the plated Pd / Ni. Gold cannot be attached.

[0171] The specific manufacturing process of continuous terminal products is:

[0172] Using the usual roll-to-roll continuous terminal surface treatment production line, the continuous terminal material is introduced into the electrolytic degreasing tank through the discharge buffer machine to clean and rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com