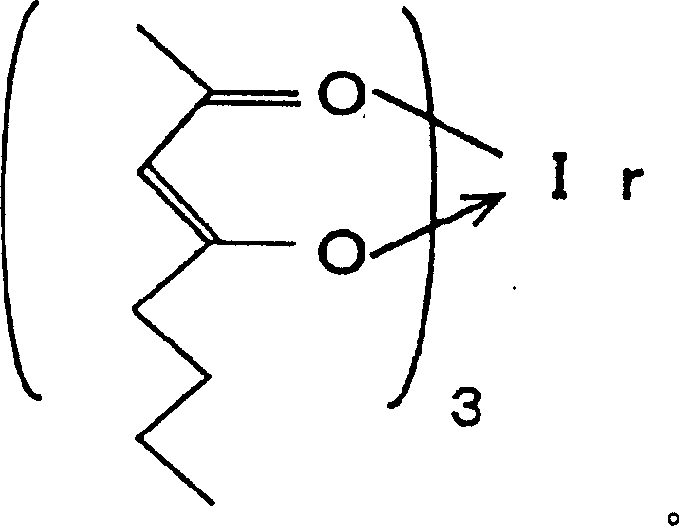

Raw material composition for CVD and its manufacturing method and chemical gas-phase evaporation plating method of iridium or iridium compound film

A compound and raw material technology, applied in gaseous chemical plating, organic chemistry, metal material coating process, etc., can solve the problems of narrowing of the scope of application, weak reactivity, inability to obtain iridium oxide films, etc., and achieve good reactivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

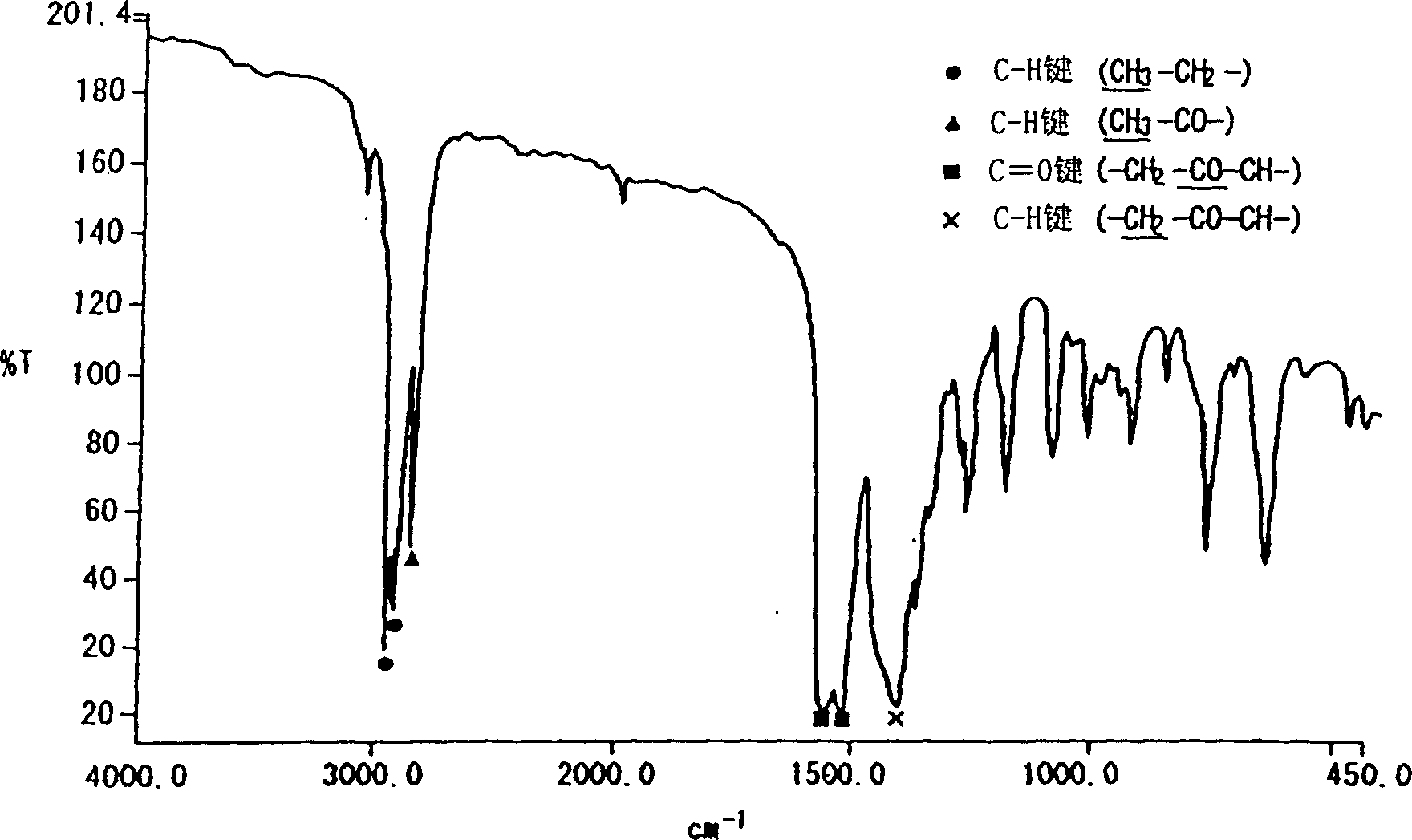

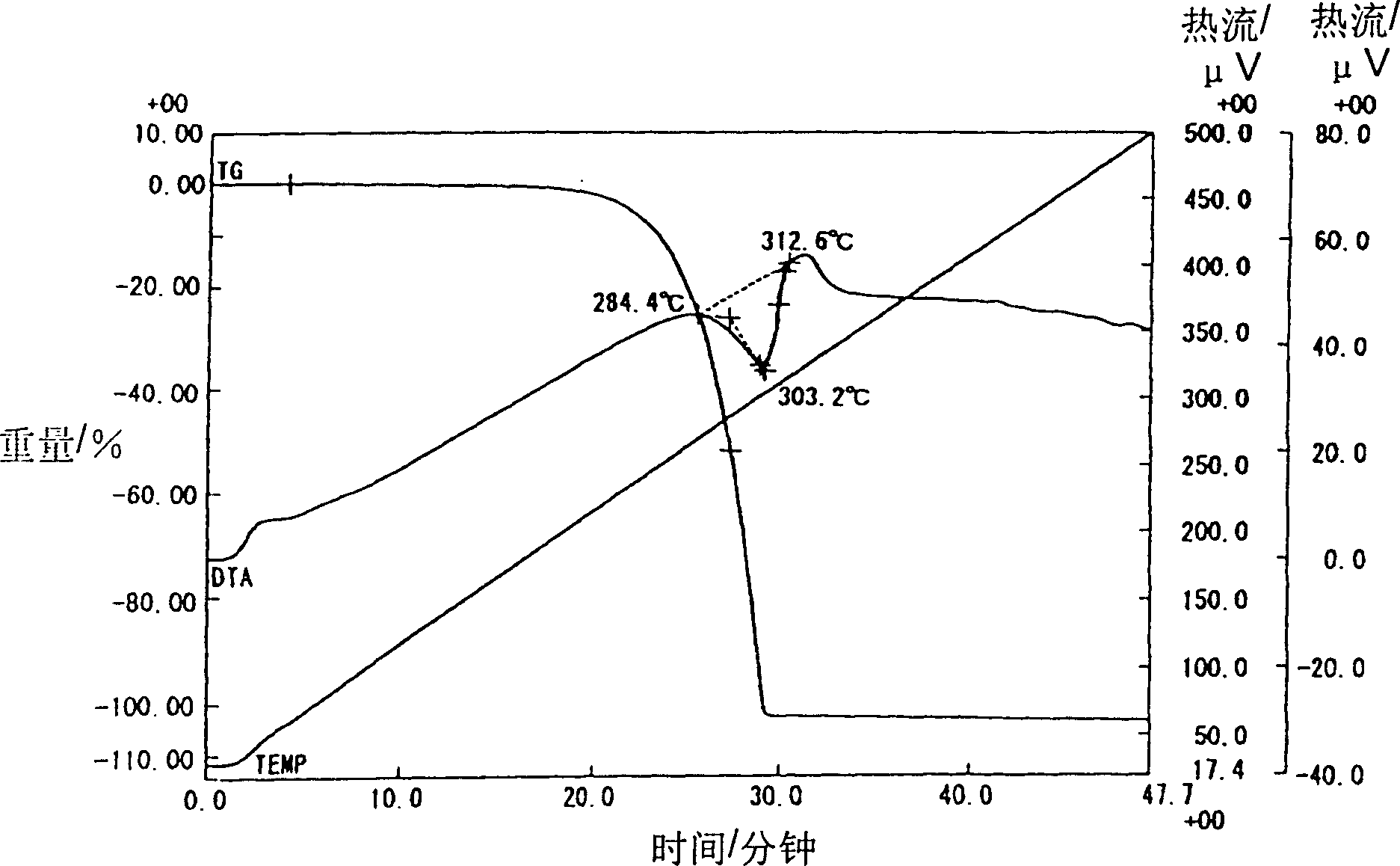

Method used

Image

Examples

Embodiment approach 1

[0041] Embodiment 1 (preparation of organic iridium compound): at 93-95°C, make 32.5g (87.5mmol) of iridium chloride trihydrate and 38.64g (271.25mmol) of 2,4-octanedione take water as solvent After heating to reflux in a separable flask for 2 hours, potassium bicarbonate was added thereto to adjust the pH of the solution to 8.0 (addition amount: 60.15 g). Then, the solution was heated to reflux at 93 to 95° C. for 5 hours to allow the reaction to proceed.

[0042] The reaction solution was transferred to a separatory funnel and extracted with benzene. This extraction operation was repeated 4 to 5 times until the benzene layer was transparent. After reducing the weight of the above-obtained extract with a rotary evaporator, extract again with water, and then add anhydrous magnesium sulfate to the extract (benzene layer) to dehydrate the extract. The extract after the dehydration treatment was sucked and filtered to remove magnesium sulfate, and concentrated with a rotary eva...

Embodiment approach 2

[0061] Embodiment 2 (manufacture of iridium oxide thin film): Hereinafter, using the trans-tris(2,4-octanedionate) iridium obtained in Embodiment 1 as a raw material, an iridium oxide thin film was manufactured by CVD. The reaction conditions in the CVD step were set as follows.

[0062] Raw material heating temperature: 150℃

[0063] Carrier gas (argon) flow: 45sccm

[0064] Reaction gas (oxygen) flow: 45sccm

[0065] Reactor pressure: 530Pa (4 mm Hg)

[0066] Substrate temperature: 350°C

[0067] The morphology of the obtained iridium oxide thin film was observed with an AFM (atomic force microscope). As a result, the surface roughness R MS value is R MS = 2.1 nm, it was confirmed that a thin film with good morphology could be produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com