Vacuum evaporation apparatus

An evaporation and vacuum technology, which is applied in the directions of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of decreasing the effect of increasing the incident angle, reducing the proportion of the flat part of the film pattern, and blurring the pattern. , to achieve the effect of suppressing pattern blur and uniform film thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

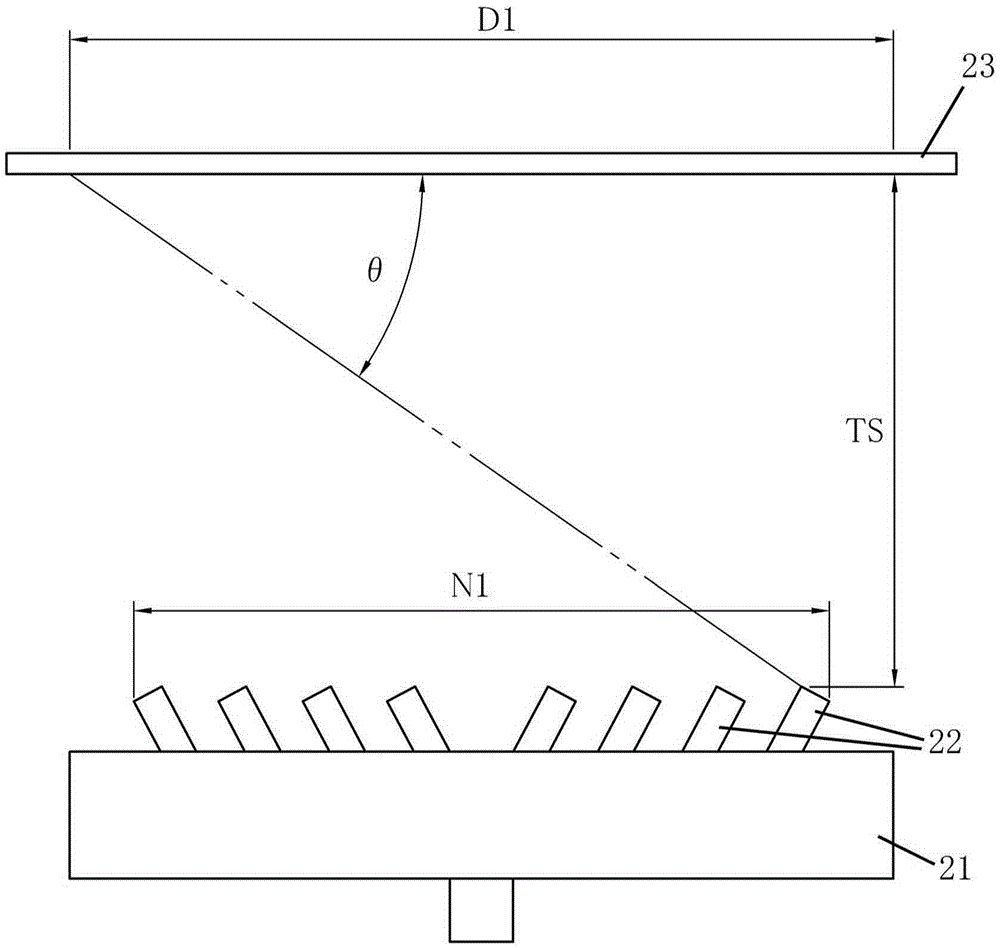

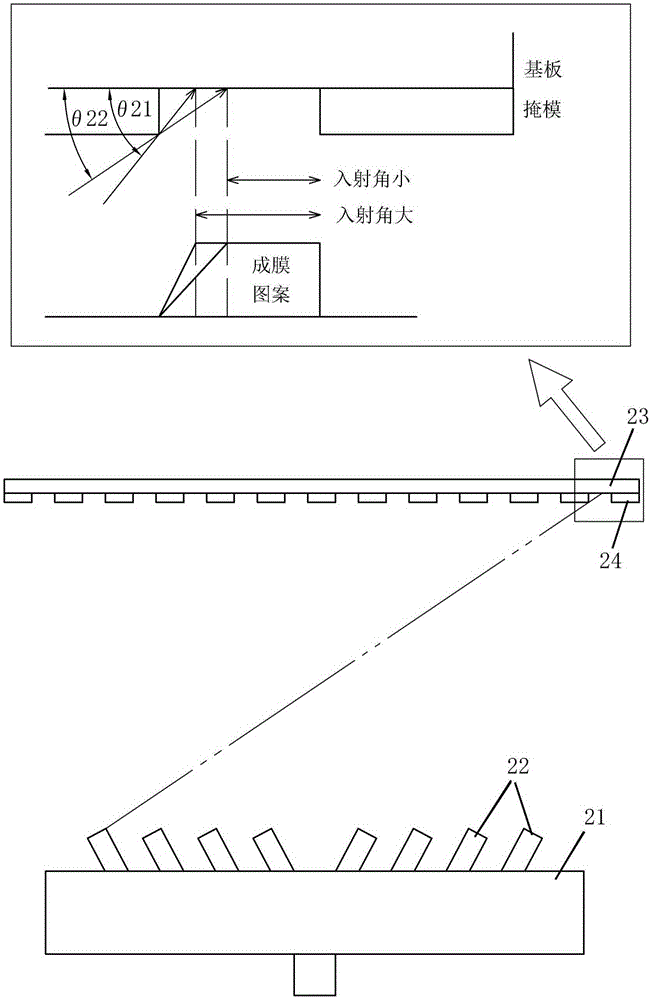

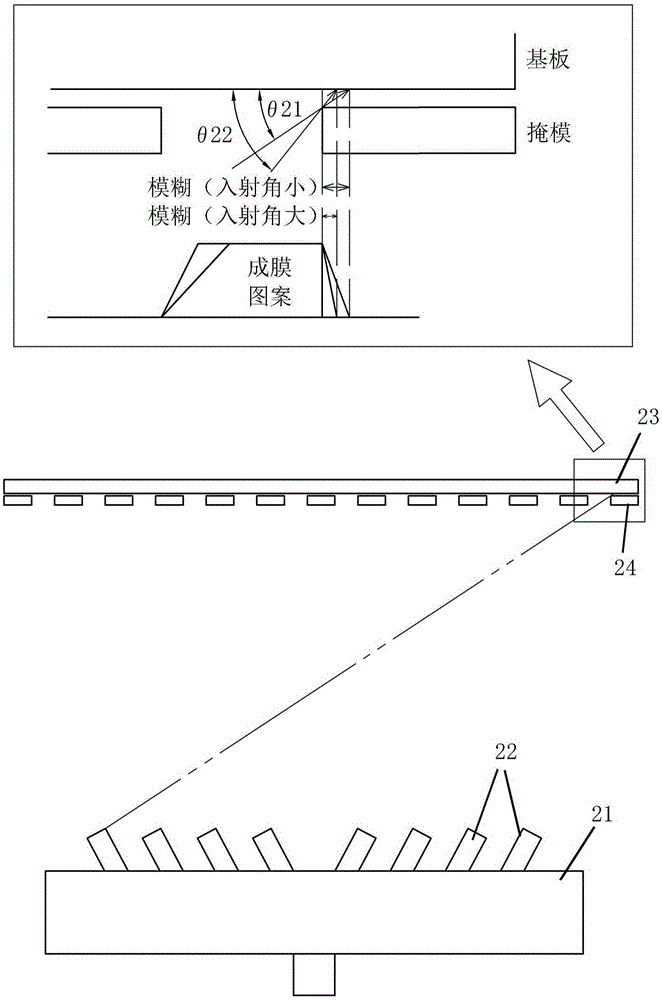

[0064] Specific embodiments of the present invention will be described with reference to the drawings.

[0065] In this embodiment, the present invention is applied to a vacuum evaporation device configured as follows: an evaporation source 1 containing a film-forming material is arranged in a vacuum tank maintaining a reduced pressure atmosphere, and multiple An evaporation port 2 is used to relatively move the evaporation source 1 and the substrate 3 disposed at a position facing the evaporation source 1 in a direction perpendicular to the longitudinal direction of the evaporation source 1. The film-forming material is ejected from the evaporation port 2 to form a vapor-deposited film on the substrate 3 .

[0066] Specifically, in this embodiment, the outermost evaporation ports 2 provided at the outermost ends of the plurality of evaporation ports 2 are each configured to have an inclination toward the outside in the longitudinal direction of the evaporation source 1 . At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com