Method of liquid-drop jet coating and method of producing display devices

A technology of droplet spraying and coating method, which is applied to the device, coating, furnace and other directions of coating liquid on the surface, which can solve the problems of difficult shape control and shape control, and achieve the effect of uniform film thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

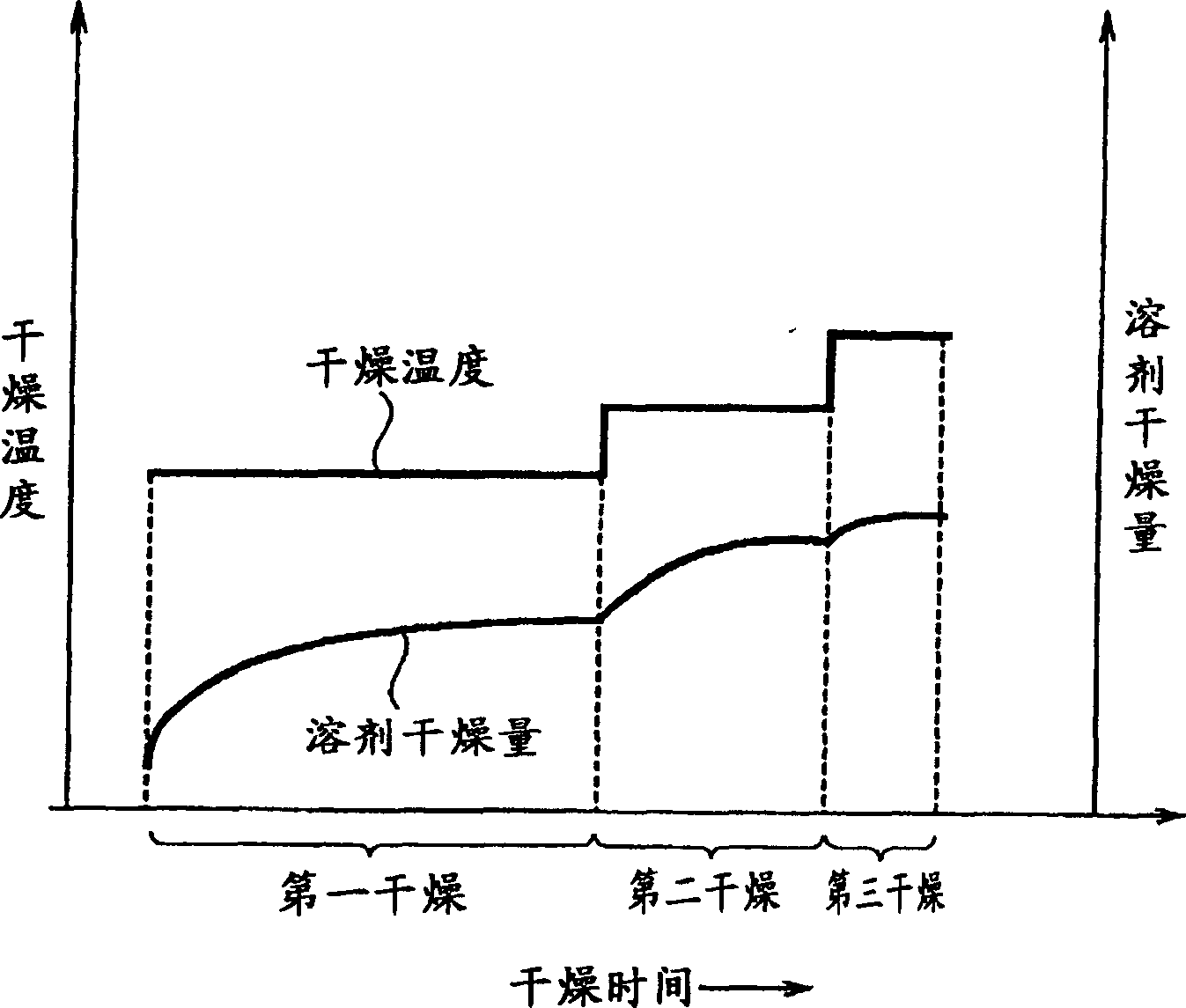

[0041] As a solvent, a pigment ink containing glycerol at a ratio of 1, ethylene glycol at a ratio of 30, and water at a ratio of 70 is coated on the substrate, such as figure 1 As shown, the above-mentioned pigment ink can be dried by heating at 80°C for 5 minutes during the first drying, heating at 120°C for 3 minutes during the second drying, and heating at 180°C for 1 minute during the third drying, and a good film can be obtained. Thick distributed film. On the contrary, when the same pigment ink as the above-mentioned pigment ink is coated on a substrate and dried by heating at 120° C., heat convection is remarkably generated during the drying process, and the film thickness distribution varies in the obtained film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com