Barrier-film forming apparatus, barrier-film forming method, and barrier-film coated container

a technology of barrier film and forming method, which is applied in the direction of packaging foodstuffs, transportation and packaging, packaged goods types, etc., can solve the problems of difficult to realize such a similar shape, inability to obtain the barrier property for practical use, and the non-uniformity of formed films is greatly increased. achieve the effect of high barrier property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

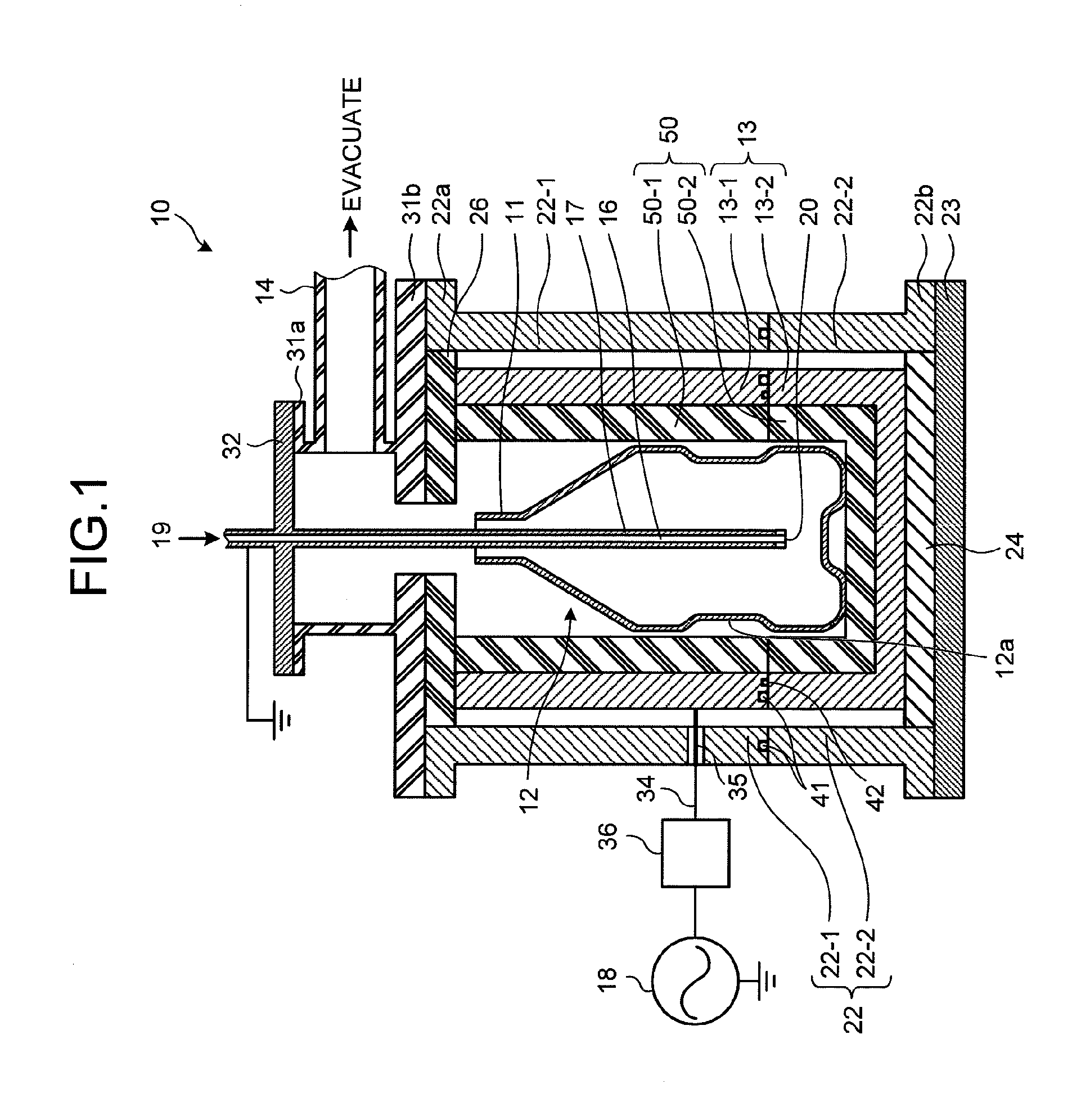

[0104]A barrier-film forming apparatus according to a first embodiment of the present invention will be explained with reference to the accompanying drawings.

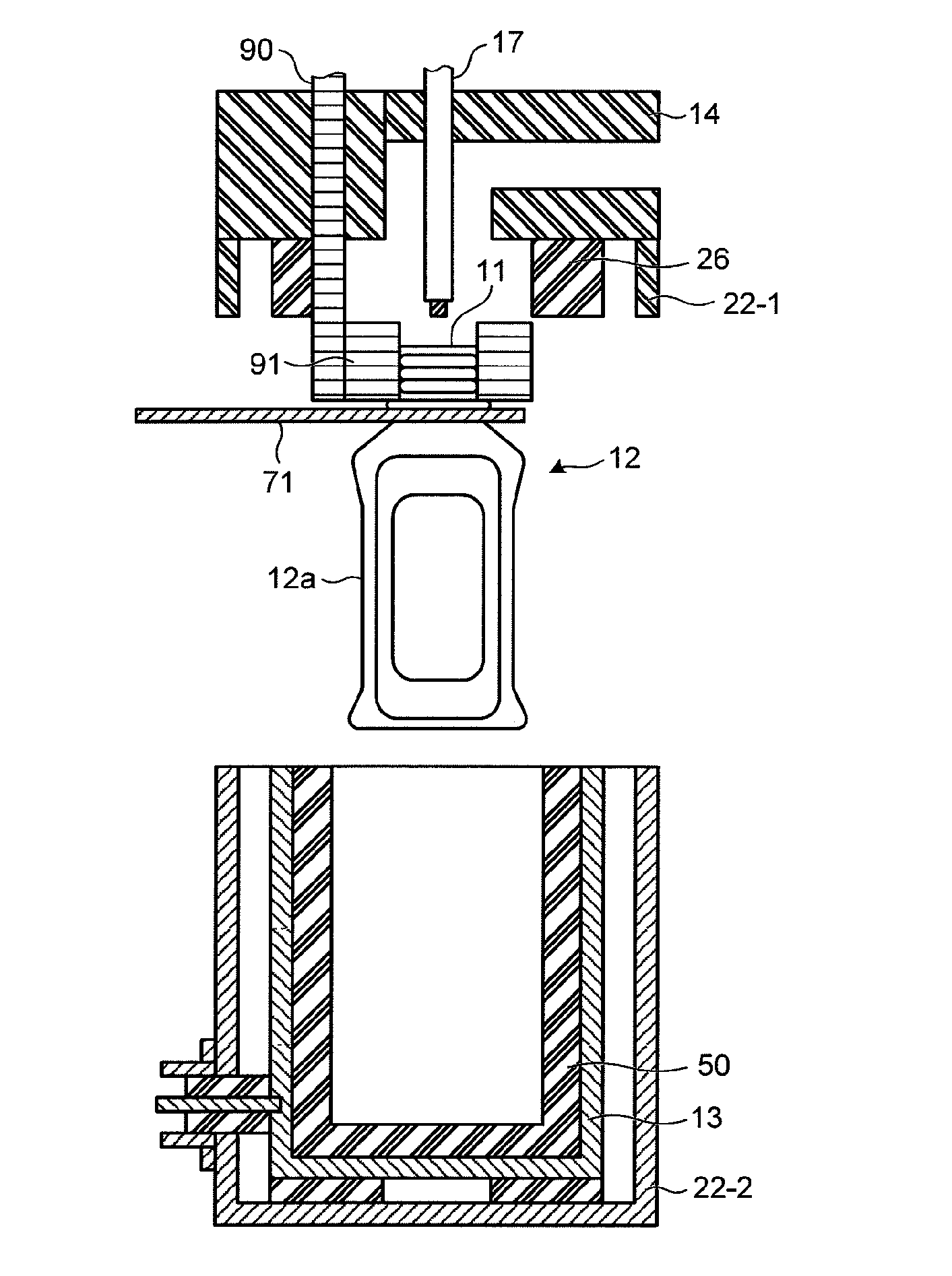

[0105]FIG. 1 is a conceptual diagram of the barrier-film forming apparatus according to the present embodiment. The same members as those in the barrier-film forming apparatus according to the conventional technique explained with reference to FIG. 38 are denoted by like reference numerals and redundant explanations thereof will be omitted.

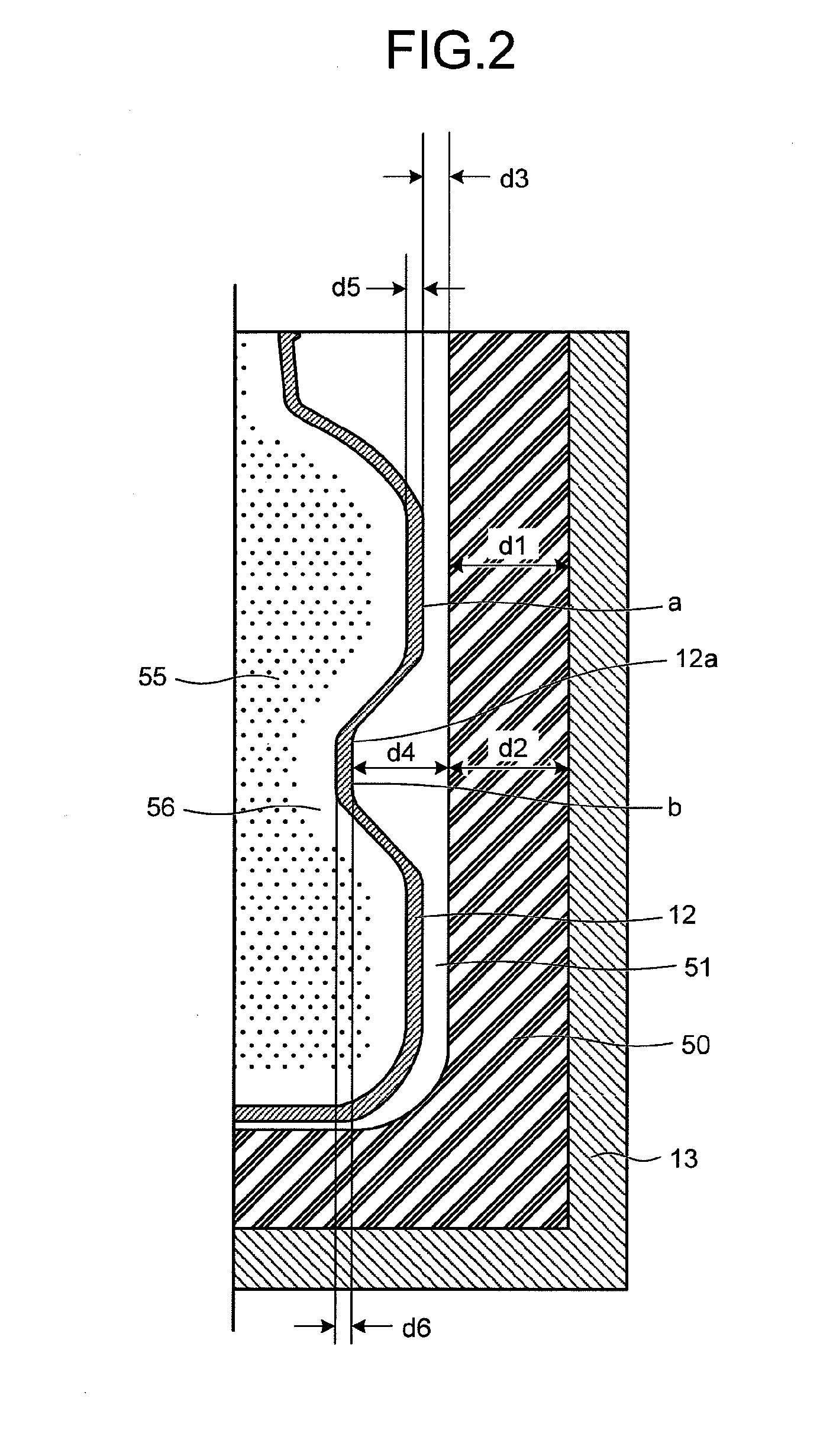

[0106]As shown in FIG. 1, a barrier-film forming apparatus 10 according to the present embodiment forms a barrier film on an inner face of a processing target, which is the plastic container (hereinafter, also “container”) 12 having at least one concave or convex portion 12a. The barrier-film forming apparatus 10 includes a dielectric member 50 that has a cavity sized to enclose at least a major portion of the container 12, the external electrode 13 that covers an outer circumference of the d...

second embodiment

[0229]FIG. 16 is a schematic diagram of a barrier-film forming apparatus according to another embodiment of the present invention.

[0230]As shown in FIG. 16, the shape of the container 12 is changed to have a circular cross section, and the clearance 51 is at least 3 millimeters.

[0231]According to the present embodiment, even when the clearance 51 between the dielectric member 50 and the container 12 is increased, a uniform and satisfactory film (having the BIF fifteen times higher or a higher BIF) can be formed on the inner face of the container.

third embodiment

[0232]FIG. 17 is a schematic diagram of a barrier-film forming apparatus according to still another embodiment of the present invention.

[0233]As shown in FIG. 17, the shape of the container 12 is changed to have a circular cross section, and the clearance 51 is at least 1 millimeter.

[0234]A dielectric member 62 of a convex shape corresponding to a concave portion 12b at the bottom of the container is further provided.

[0235]According to the present embodiment, uniform film formation can be achieved also at the concave portion 12b at the bottom of the container, as well as the concave portion 12a at the body of the container.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com