Magnet unit, and magnetron sputtering device

一种磁控溅射装置、磁铁单元的技术,应用在溅射镀覆、电气元件、离子注入镀覆等方向,能够解决限制、不能调整磁轨长度等问题,达到膜厚分布均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

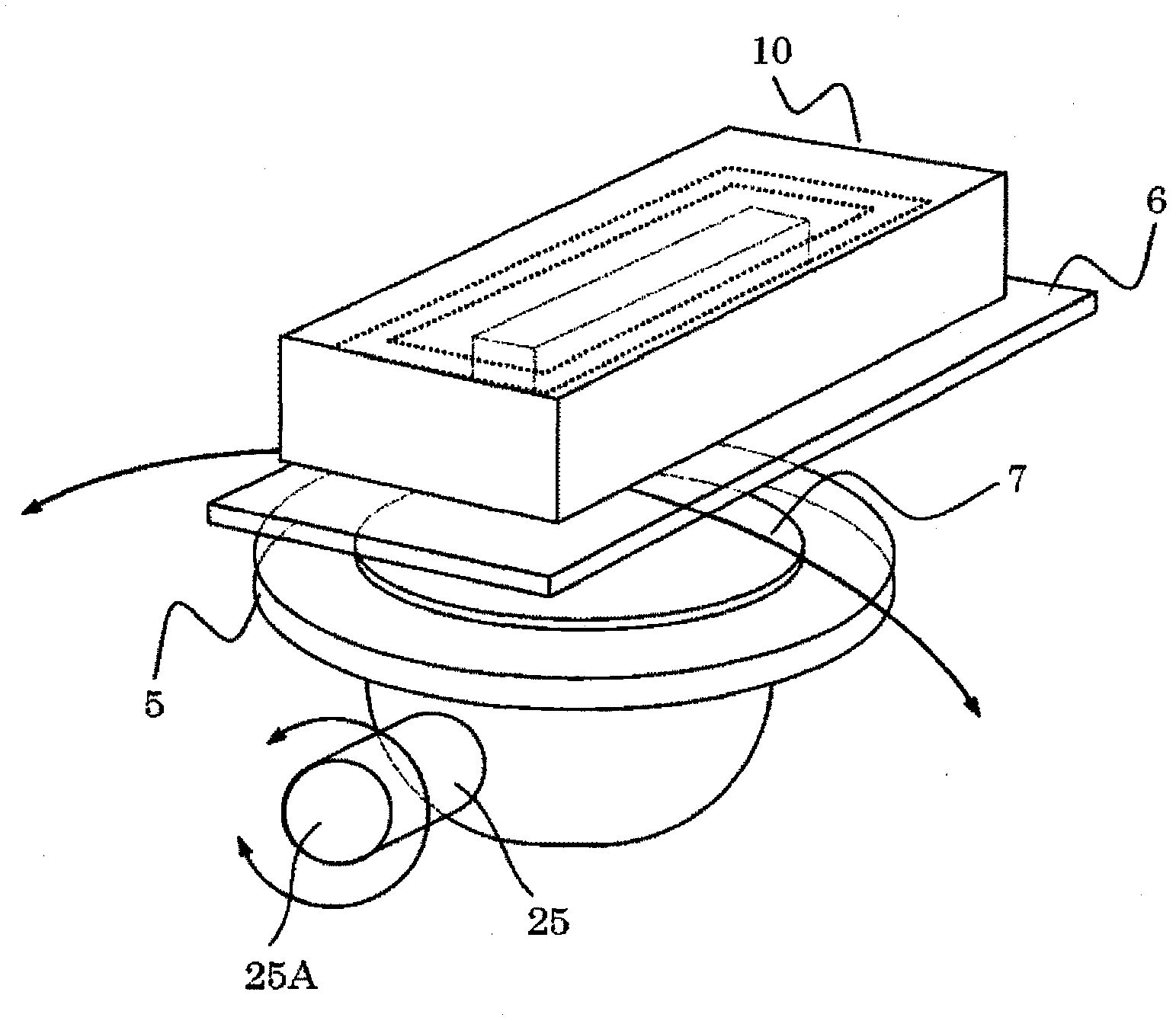

[0044] Next, refer to Figure 4 The magnet unit 10 of the first embodiment mounted in the sputtering apparatus 1 described above will be described. Figure 4 It is a top view showing the structure of the magnet unit of 1st Embodiment.

[0045] Such as Figure 4 As shown, the magnet unit 10 of the present embodiment has a yoke 20 having the same shape (rectangular shape) as the target 6 and made of a ferromagnetic plate material on the back side of the cathode electrode. The yoke is provided with an annular outer magnet 30 arranged along the outline of the target 6 , and an inner magnet 40 arranged in the outer magnet and having a polarity different from that of the outer magnet 30 .

[0046] As described above, the main body (first magnetic pole) 31 of the outer peripheral magnet 30 is formed in a ring shape (rectangular frame shape) along the outline of the target 6 .

[0047] The inner magnet 40 arranged in the main body (first magnetic pole) 31 of the outer peripheral ma...

no. 2 Embodiment approach

[0059] Next, refer to Figure 7 The magnet unit 50 of the second embodiment mounted in the sputtering apparatus 1 described above will be described. Figure 7 It is a plan view which shows the structure of the magnet unit of 2nd Embodiment. In addition, the same code|symbol is attached|subjected and demonstrated about the same component as 1st Embodiment.

[0060] Such as Figure 7 As shown, in the magnet unit 50 of the second embodiment, the structures of the yoke 20 and the outer peripheral magnet 30 are the same as those of the first embodiment. That is, a yoke 20 having the same rectangular shape as the target 6 and made of a ferromagnetic plate is provided on the back side of the cathode electrode. In addition, the main body (first magnetic pole) 31 of the outer peripheral magnet 30 is formed in a rectangular frame shape along the outline of the target 6 . In addition, n−1 protruding magnetic pole portions (second magnetic poles) 32 are protruded from both ends of the...

Embodiment 1

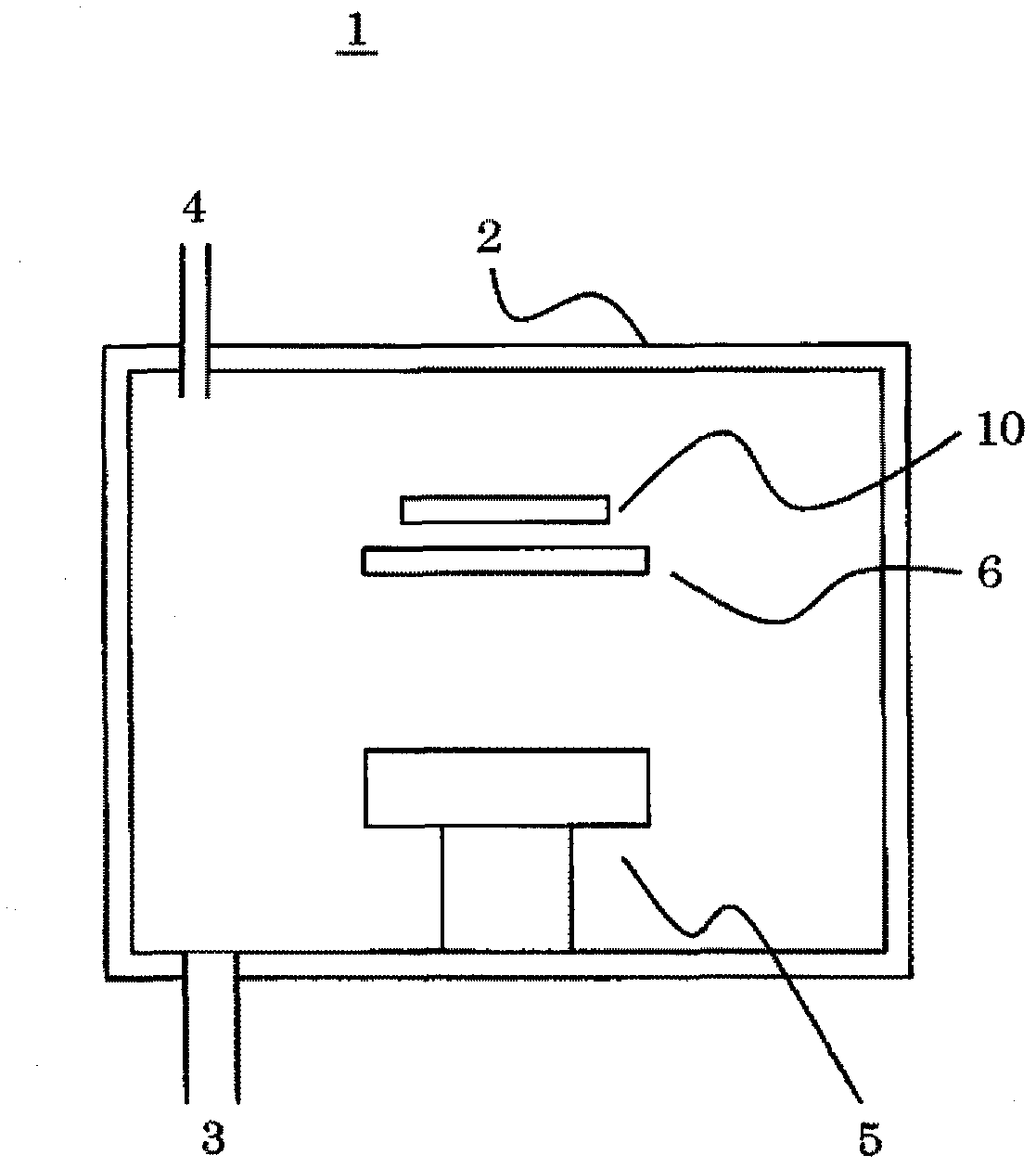

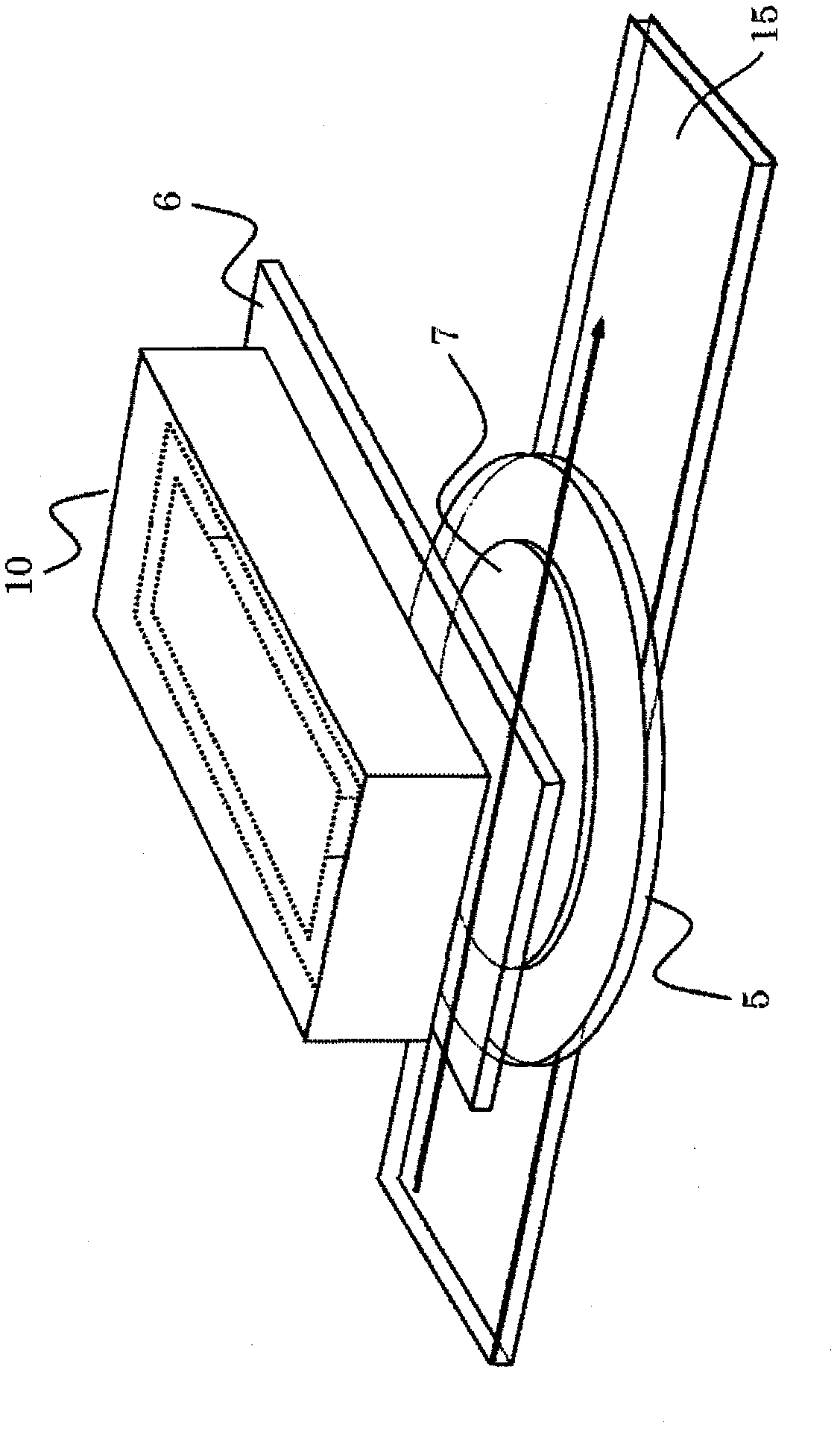

[0074] In Example 1, using figure 1 The sputtering device 1 and figure 2 The transport mechanism (guide rail) 15 supports a plurality of silicon substrates on the guide rail, moves the guide rail in a direction perpendicular to the longitudinal direction of the target, and forms a titanium nitride film on each substrate.

[0075] Using titanium (Ti) as the target 6 supported on the cathode electrode, Ar, N 2 The mixed gas is introduced into the vacuum container 2 as a process gas.

[0076] Figure 10 It is an explanatory diagram showing the state of film formation in Example 1 in relation to the prior art. Such as Figure 10 As shown in (A) and (C), when a conventional magnet unit is mounted in the sputtering apparatus 1, the film thickness changes in the outer peripheral portions of the substrate corresponding to both ends in the longitudinal direction of the target 6 are observed. Thin.

[0077] In contrast to this, as Figure 10 As shown in (B) and (D), when the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com