Susceptor and vapor growth device

A technology of vapor phase growth and susceptors, applied in the field of susceptors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

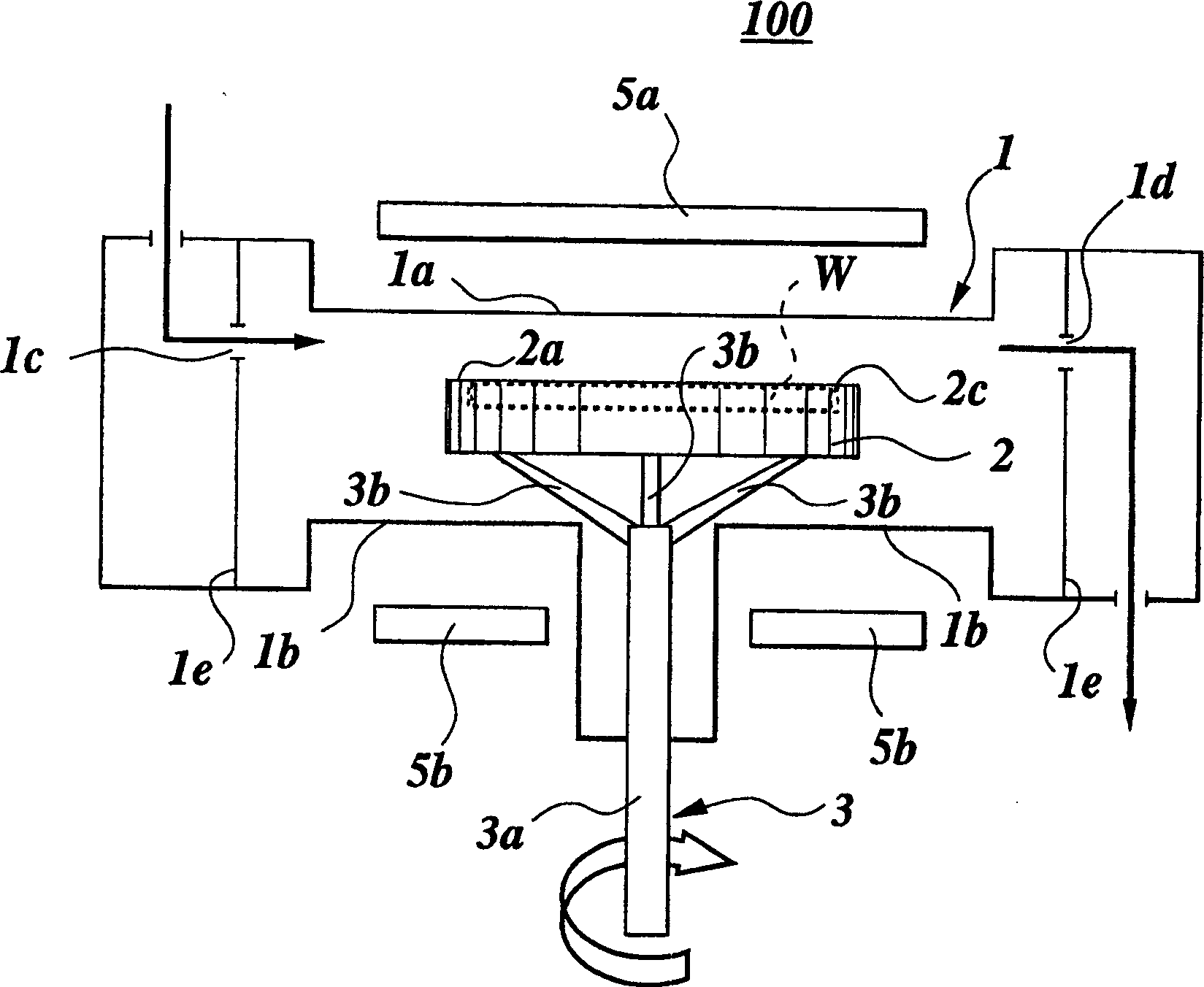

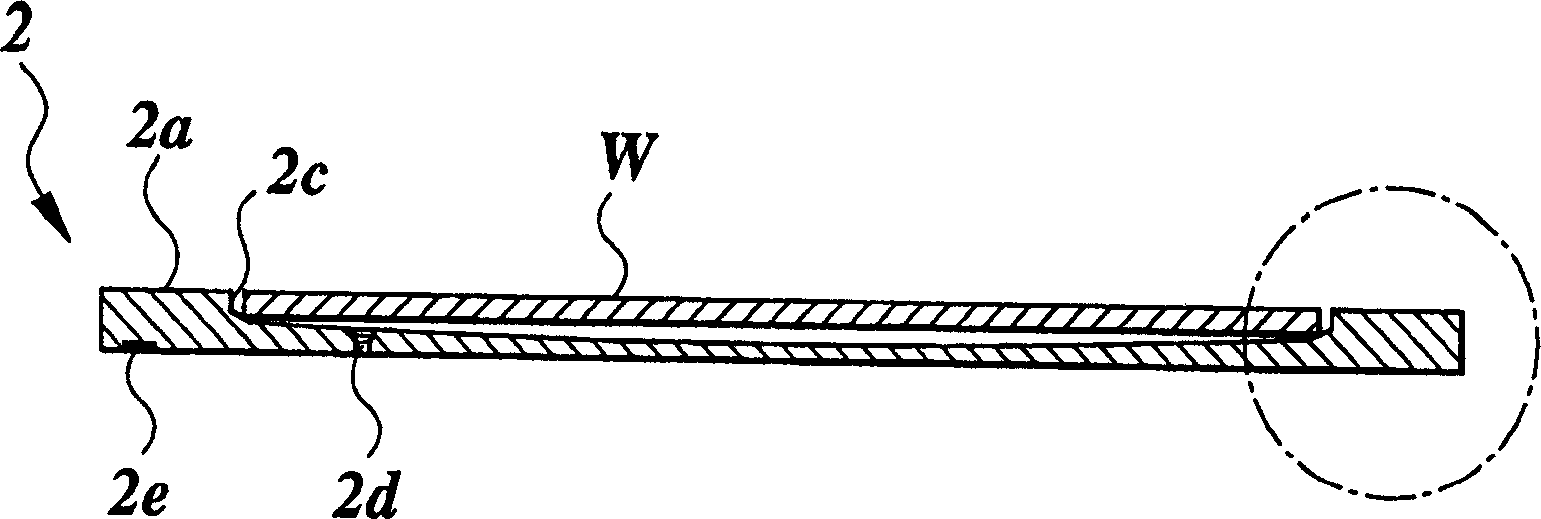

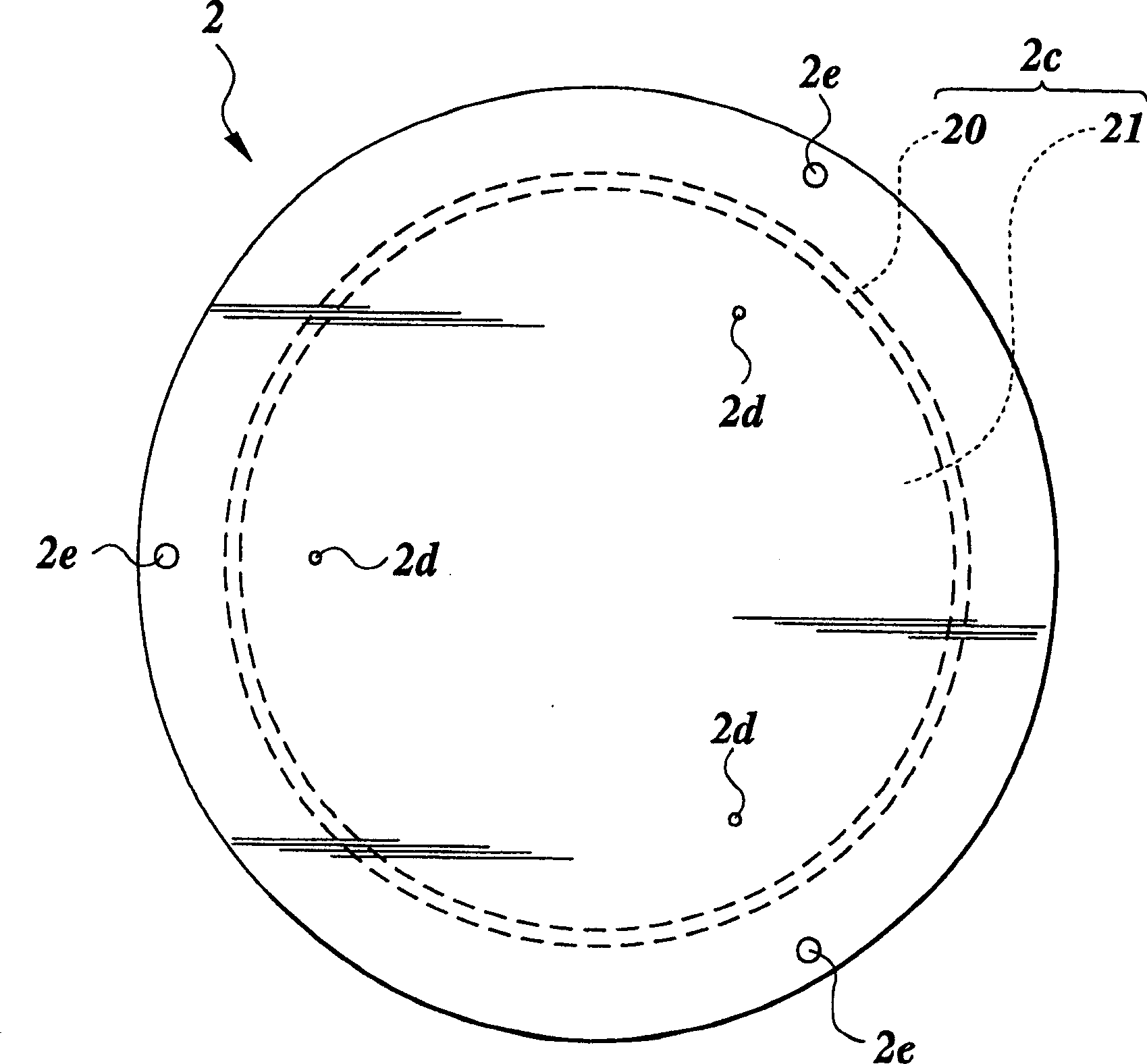

[0020] Next, an embodiment of the vapor phase growth apparatus according to the present invention will be described with reference to the accompanying drawings. This embodiment of the vapor phase growth apparatus is a single-wafer type vapor phase growth apparatus that vapor-grows a single-crystal thin film on the front surface of a semiconductor substrate.

[0021] figure 1 It is a longitudinal cross-sectional view of a schematic structure of the vapor phase growth apparatus 100 . The vapor phase growth apparatus 100 is a single wafer type vapor phase growth apparatus, and includes a reactor 1 in which a semiconductor substrate W such as a silicon single crystal substrate or the like is placed.

[0022] The reactor 1 is a reaction chamber having a top wall 1a, a bottom wall 1b and a side wall 1e. The top wall 1a and the bottom wall 1b are made of translucent quartz. A gas supply opening 1c for supplying a reaction gas for vapor phase growth into the reactor 1 and a gas di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com