Vapor growth graphite fiber composition, its mixture and application

A technology of graphite fiber and vapor phase growth, applied in the direction of graphene, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as adverse effects, affecting the performance of composite materials, reducing the number of continuous networks, etc., to improve electrical conductivity , improve performance, increase the number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

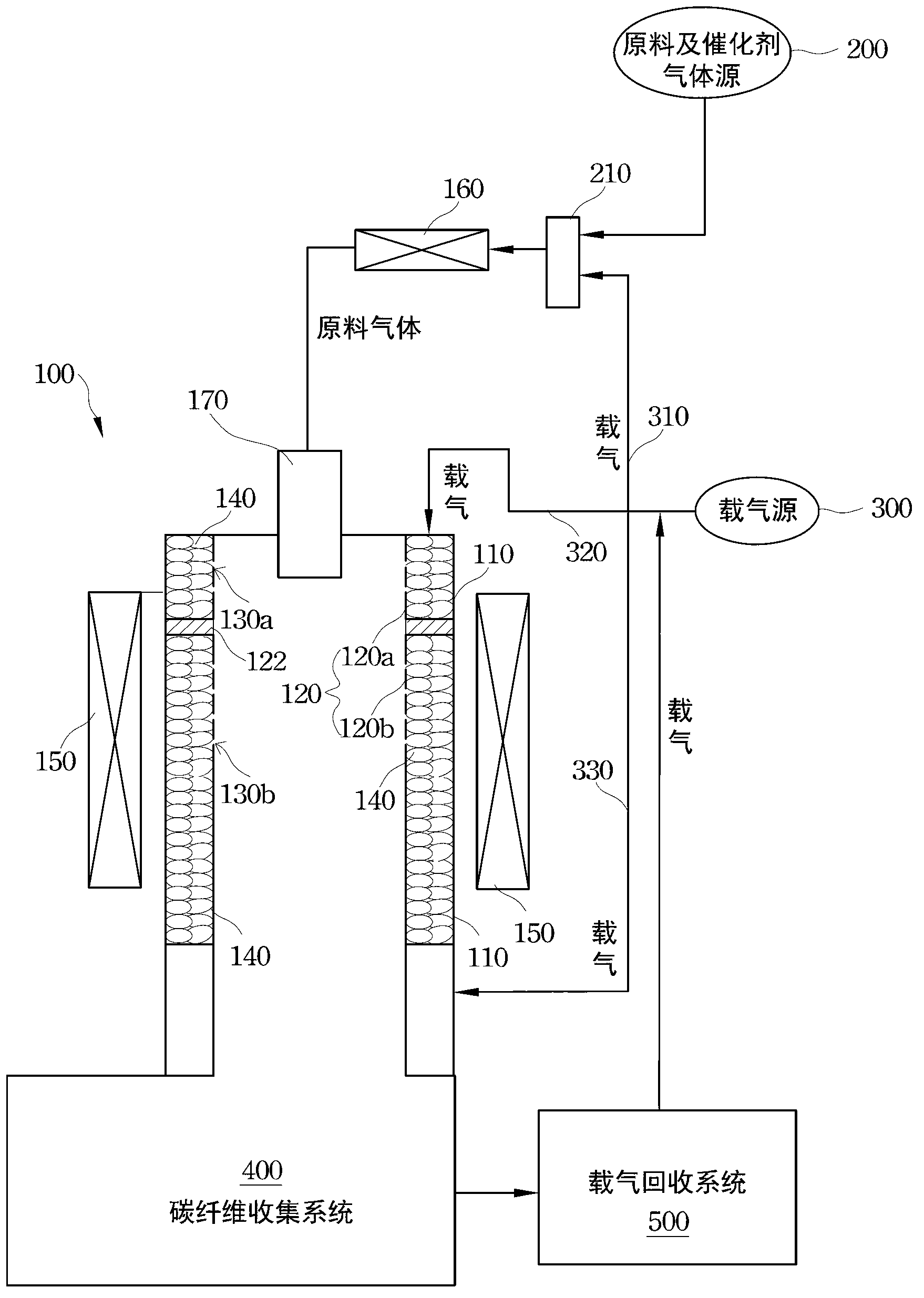

[0041] Firstly, the gas source 200 composed of hydrocarbons, catalysts and co-catalysts delivers the raw gas to the mixer 210 . After being uniformly mixed with part of the carrier gas, the reaction gas of the raw material gas and the carrier gas is sent to the preheater 160 to be preheated to 300°C. Next, the preheated reaction gas is introduced into the reaction furnace body through the gas inlet conduit 170 for reaction. At the same time, the remaining carrier gas is transported to the space between the inner tubes 120a and 120b and the outer tube 110 by the pipeline 320 and the pipeline 330 respectively. The space between the inner tube 120 and the outer tube 110 is filled with a thermally conductive material 140, and the heater 150 heats the reaction furnace outside the tube. (outer tube 110 ) and the thermally conductive material 140 , after the carrier gas is heated by the thermally conductive material 140 , it is ejected from the holes 130 a and 130 b and sent into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com