Fine carbon fiber mixture and composition thereof

A technology of carbon fibers and mixtures, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve problems that are not suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] The present invention will be described below by way of examples.

[0070] (Example)

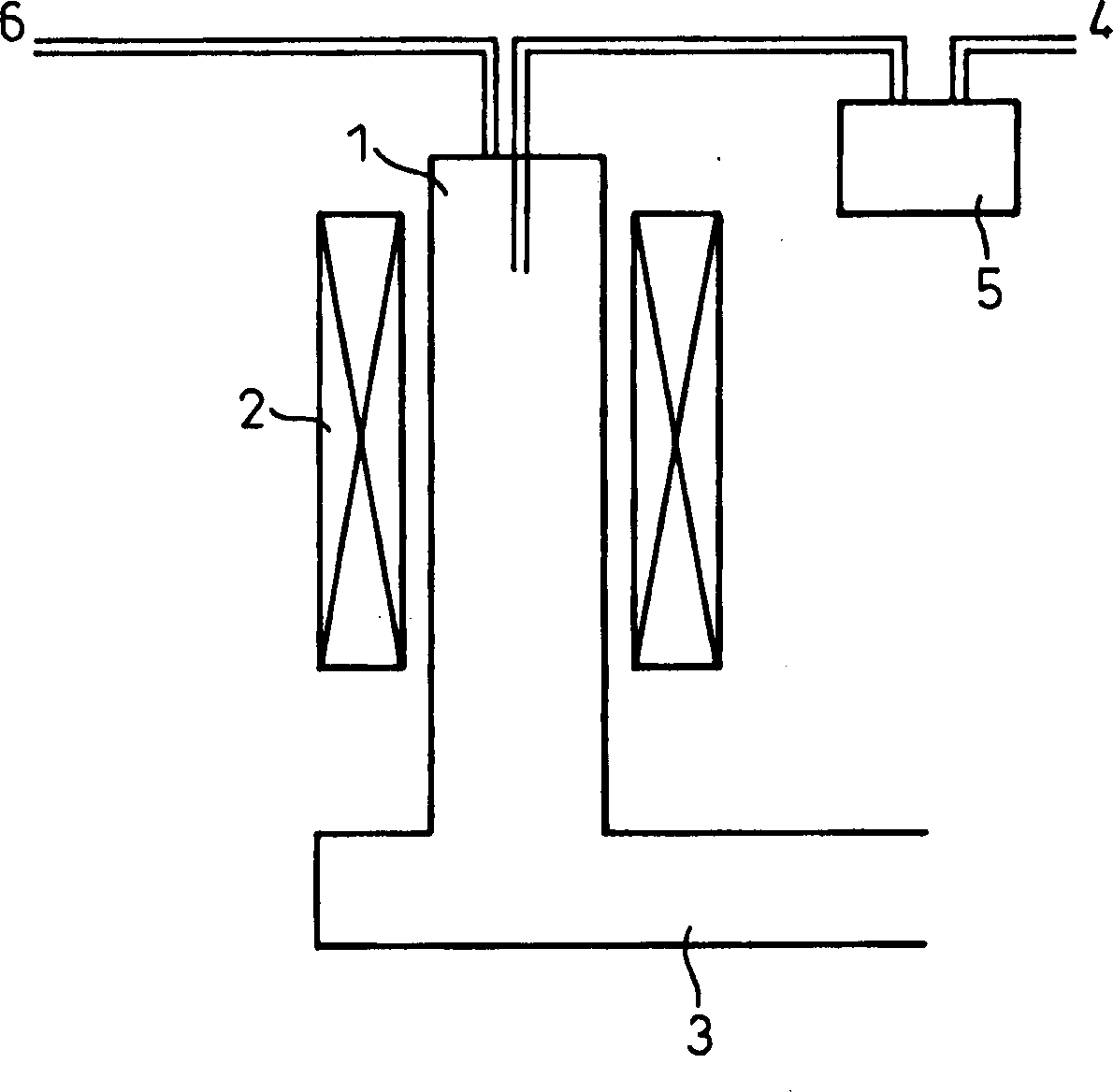

[0071] Such as figure 1 As shown schematically, the raw material feed pipe 4 and the carrier gas feed pipe 6 for adding the raw material gasified in the raw material gasification device 5 are arranged on the top of the vertical heating furnace 1 (inner diameter: 170mm, length: 1500mm) .

[0072]Benzene containing ferrocene (4% by mass) and thiophene (5% by mass (1.9% by mass when converted to atomic sulfur)) was gasified, and the gasified product was fed through the raw material feed pipe 4 at a rate of 15 g / min. , while maintaining the temperature of the product at 200°C, and hydrogen gas serving as a carrier gas was fed at a rate of 180 liters / minute, thereby allowing the reaction to proceed.

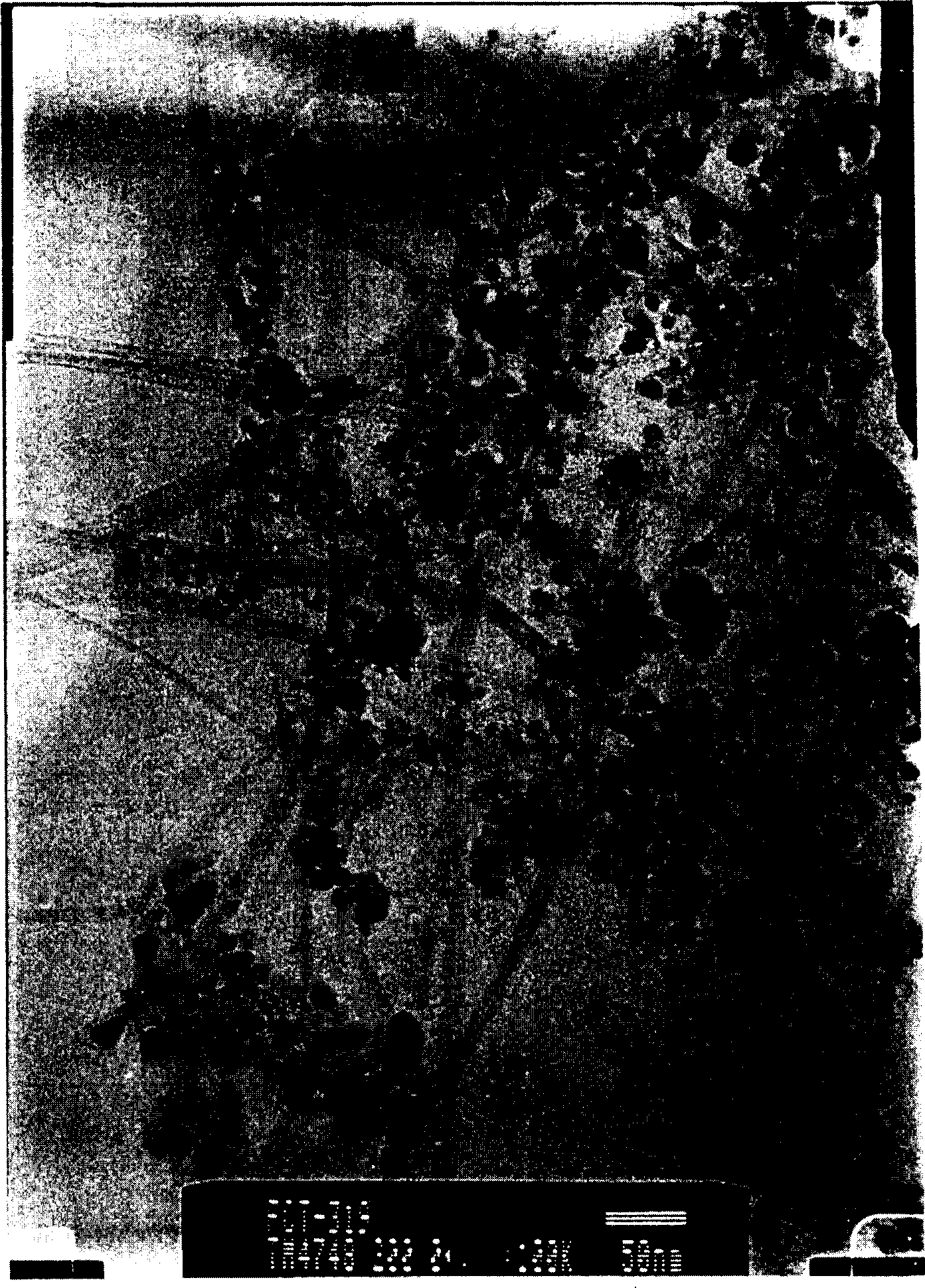

[0073] The fine carbon fibers produced by the above reaction were heat-treated at 1300° C. in an argon (Ar) atmosphere. The thus-treated fine carbon fibers were further subjected to heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com