Production method for silicon epitaxial wafer, and silicon epitaxial wafer

A technology of silicon epitaxial wafers and manufacturing methods, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, gaseous chemical plating, etc., can solve problems such as shape deterioration, and achieve suppression of unevenness, elimination of discrete, good flatness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

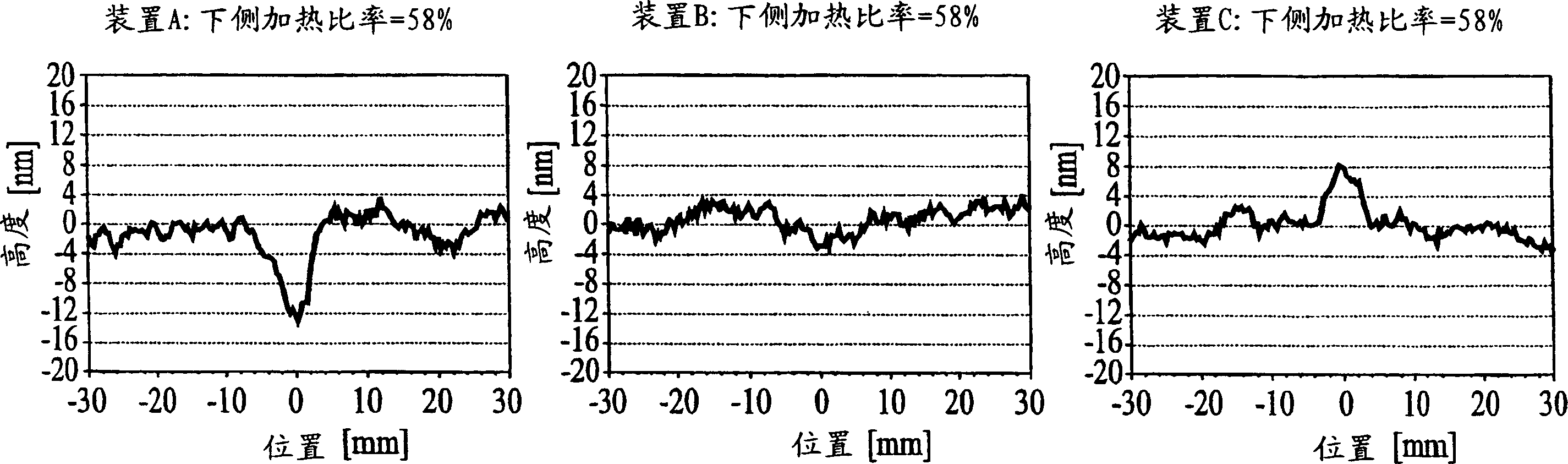

[0060] Using the ejector-type vapor phase growth apparatus A, the heating ratio of the upper heating device 14a and the lower heating device 14b is changed to (44%:56%), (46%:54%), (48%:52%) , for epitaxial growth. Regarding the silicon epitaxial wafers respectively obtained at this time, the surface shape of the silicon epitaxial layer near the push pin 13 was measured, Figure 5 The measurement results are shown.

[0061] from Figure 5 As a result, it can be seen that when the output of the lower heating device 14b is relatively lower than that of the upper heating device 14a (for example, when the output of the lower heating device is 52%), the surface of the silicon epitaxial layer at the position corresponding to the ejector pin 13 The shape is convex. That is, when the output of the lower heating device 14b is lowered, the temperature of the susceptor 20 is lowered, so the temperature of the back surface of the silicon wafer W is lowered, and the temperature of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com