Method and device for continuously preparing carbon nano-tube composite thin film or fiber

A kind of carbon nanotube composite, carbon nanotube technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

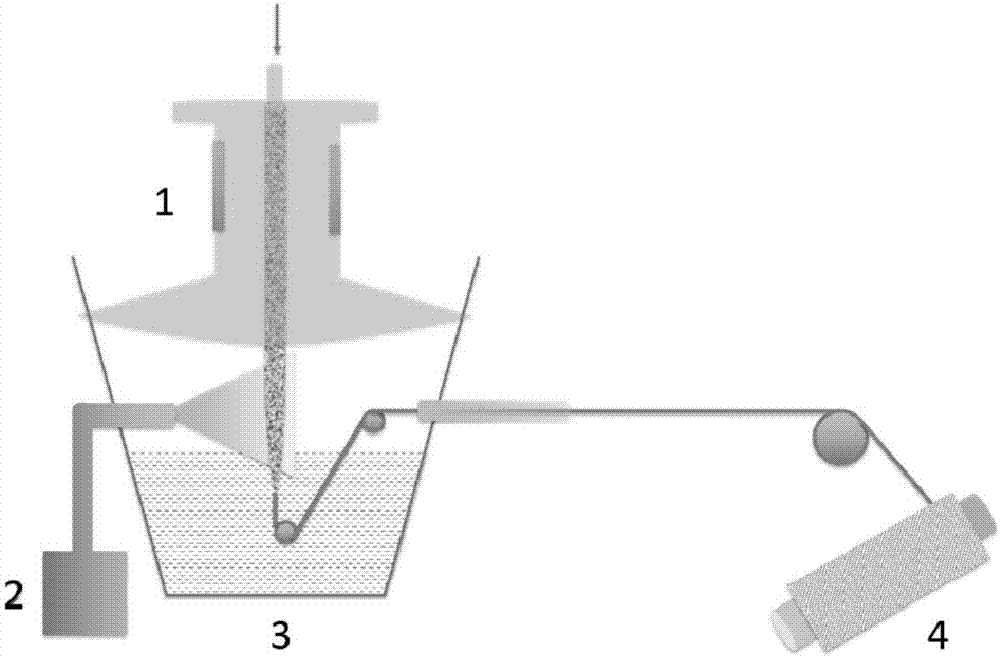

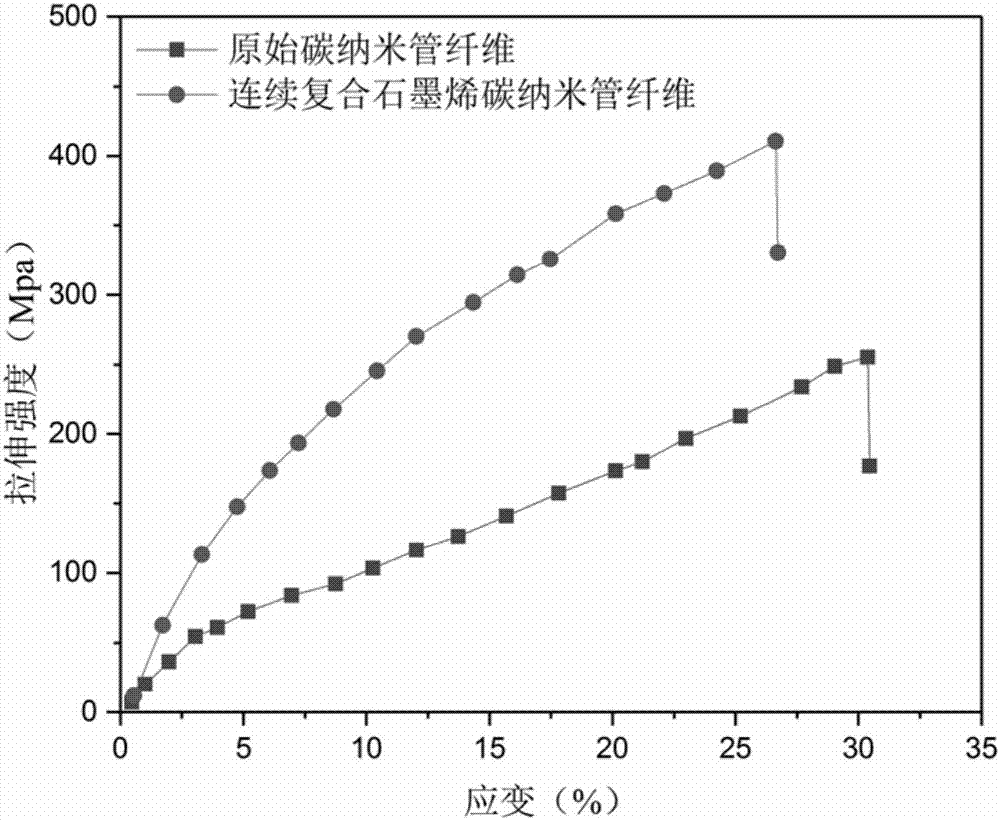

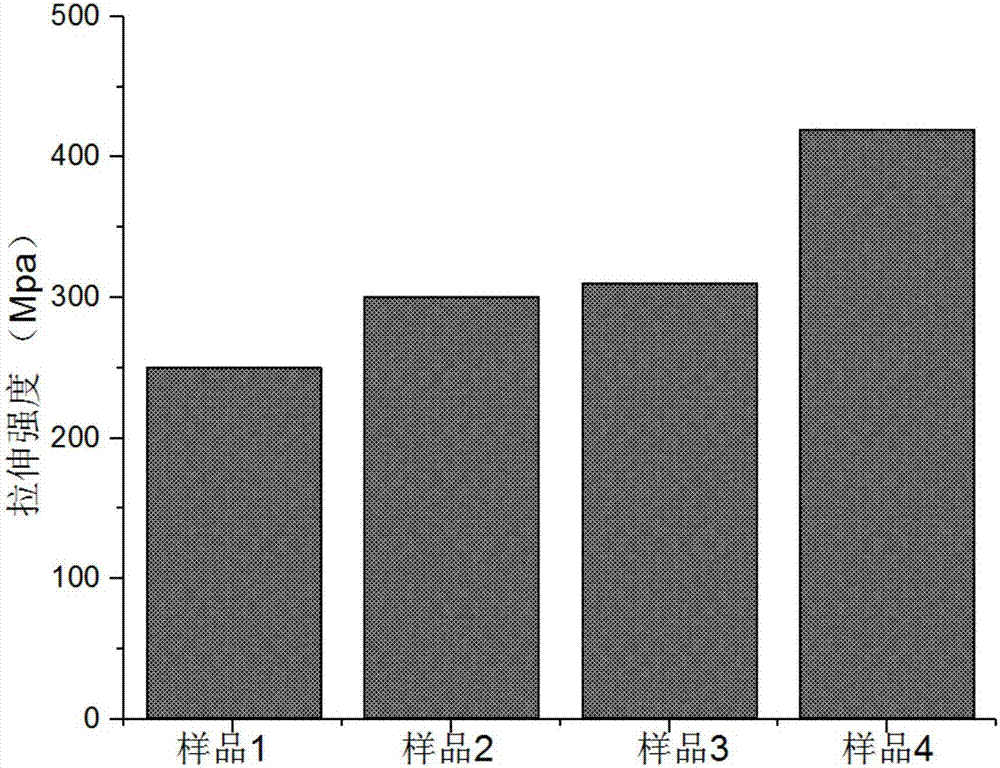

Embodiment 1

[0074] Example 1 see figure 1 As shown, the present embodiment prepares carbon nanotube aggregates by the floating catalytic chemical vapor deposition method, and an injector is added at the outlet of the reaction zone, and the injector is filled with a graphene oxide water dispersion with a concentration of 0.5mg / ml. The nanotube aggregates are continuously sprayed before entering the liquid seal tank, and then the carbon nanotube composite aggregates are driven by the roll to pass through the liquid seal tank filled with water at a speed of 0.1m / min to 1m / min to obtain carbon nanotubes / Graphene composite fiber, and then the obtained composite fiber is passed through a flat heater, and finally twisted to obtain the finished carbon nanotube / graphene composite fiber, and its mechanical tensile curve can be found in figure 2 and image 3 Sample 4 in .

Embodiment 2

[0079] Example 2 see figure 1As shown, the present embodiment prepares carbon nanotube aggregates by the floating catalytic chemical vapor deposition method, and an injector is added at the outlet of the reaction zone, and the injector is filled with a graphene oxide aqueous dispersion with a concentration of 0.5 mg / ml. The container of the graphene oxide aqueous dispersion has an ultrasonic function. After 30 minutes, 600W ultrasonic, the graphene oxide aqueous dispersion with a smaller size is obtained, which is continuously sprayed before the carbon nanotube aggregate enters the liquid seal tank, and then passed through the roll Drive the carbon nanotube aggregates to pass through the liquid-sealed tank evenly at a certain speed to obtain carbon nanotube / graphene composite fibers, then pass the obtained composite fibers through a flat plate heater, and finally twist to obtain carbon nanotube / graphene composite fibers finished product.

Embodiment 3

[0080] Example 3 see figure 1 As shown, the present embodiment prepares carbon nanotube aggregates by the floating catalytic chemical vapor deposition method, and an injector is added at the outlet of the reaction zone, and the injector is filled with a silver nanoparticle aqueous dispersion with a concentration of 1 mg / ml. The tube aggregates are sprayed continuously before entering the liquid seal tank, and then the carbon nanotube aggregates are driven through the liquid seal tank at a certain speed by the roll to obtain carbon nanotube / silver nanoparticle composite fibers, and then the obtained composite fibers are passed through the liquid seal tank. The flat heater is finally twisted to obtain the finished carbon nanotube / silver nanoparticle composite fiber. The electrical conductivity of the obtained composite fiber is improved by 30% to 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com