Preparation method of carbon nanotube fiber/polydimethylsiloxane composite electro-conductive elastomer

A carbon nanotube fiber and dimethylsiloxane technology is applied in the field of preparation of carbon nanotube fiber/polydimethylsiloxane composite conductive elastomer, which can solve the problem of poor durability of conductive elastomer, easy agglomeration of CNTs, Easy to pull off and other problems, to achieve the effects of excellent cycleability and durability, mature preparation technology, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

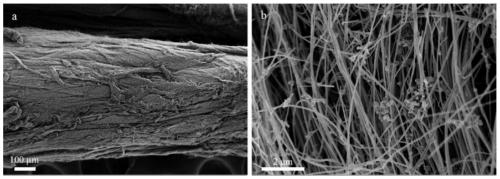

Image

Examples

Embodiment 1

[0038] Step 1: take ethanol (97.4wt%), ferrocene (1.6wt%), thiophene (8wt%) and deionized water (0.2wt%) as raw materials, after mixing, ultrasonic 30min obtains reaction solution, adopts digital syringe pump to The rate of 40mL / h is injected into a horizontal tube furnace at 1180°C, and the hollow cylinder of carbon nanotubes is prepared by floating catalytic chemical vapor deposition, and then immersed in deionized water to bundle and collect, and the air is discharged to process Twist to obtain carbon nanotube fibers, put them in an oven and dry them at 60°C for 2 hours, and set them aside.

[0039] Step 2: Add polydimethylsiloxane and curing agent into the beaker according to the mass ratio of 10:1, stir with a glass rod until fully mixed to obtain a mixed solution, and put the beaker containing the mixed solution into a vacuum drying oven , evacuated at room temperature for 1 hour until all air bubbles were removed.

[0040] Step 3: Pour 2 / 3 of the mixture that has been ...

Embodiment 2

[0046] Step 1: Take ethanol (97.4wt%), ferrocene (1.6wt%), thiophene (8wt%) and deionized water (0.2wt%) as raw materials, mix and sonicate for 30 minutes to obtain a reaction solution, and use a digital syringe pump to The rate of 30mL / h is injected into a horizontal tube furnace at 1180°C, and the hollow cylinder of carbon nanotubes is prepared by floating catalytic chemical vapor deposition, which is then immersed in deionized water to bundle and collect, and the air is discharged to process. Twist to obtain carbon nanotube fibers, put them in an oven and dry them at 60°C for 2 hours, and set them aside.

[0047] Step 2: Add polydimethylsiloxane and curing agent into the beaker according to the mass ratio of 15:1, stir with a glass rod until fully mixed to obtain a mixed solution, and put the beaker containing the mixed solution into a vacuum drying oven , evacuated at room temperature for 1 hour until all air bubbles were removed.

[0048] Step 3: Pour the 2 / 3 mixture tha...

Embodiment 3

[0054] Step 1: Take ethanol (97.4wt%), ferrocene (1.6wt%), thiophene (8wt%) and deionized water (0.2wt%) as raw materials, mix and sonicate for 30 minutes to obtain a reaction solution, and use a digital syringe pump to The rate of 28mL / h was injected into a horizontal tube furnace at 1180°C, and the hollow cylinder of carbon nanotubes was prepared by floating catalytic chemical vapor deposition, and then immersed in deionized water to bundle and collect, and the air was discharged to process Twist to obtain carbon nanotube fibers, put them in an oven and dry them at 60°C for 2 hours, and set them aside.

[0055] Step 2: Add polydimethylsiloxane and curing agent into the beaker according to the mass ratio of 18:1, stir with a glass rod until fully mixed to obtain a mixed solution, and put the beaker containing the mixed solution into a vacuum drying oven , evacuated at room temperature for 1 hour until all air bubbles were removed.

[0056] Step 3: Pour the 2 / 3 mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com